EVT stage documentation transforms engineering validation results into repeatable, reviewable baselines enabling controlled progression to production phases.

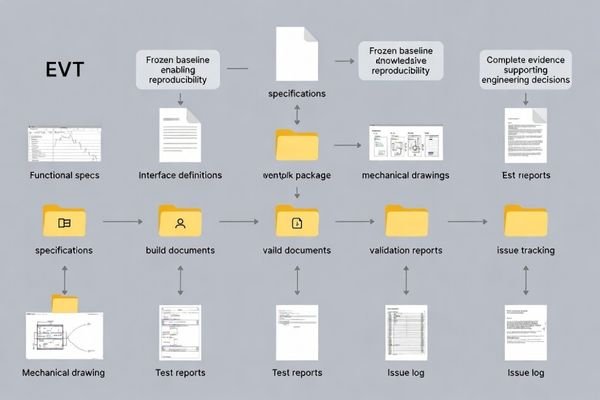

EVT deliverables should let another engineer rebuild the module, rerun the same tests, and reach the same conclusions. Provide a frozen spec baseline, controlled drawings/stack-ups and BOM with revision control, and evidence-based EVT reports tied to sample IDs, test recipes, and an issue log for clean handoff into DVT.

In my LCD display module integration work at MEIDAYINGNUO, I’ve found that EVT documentation quality1 directly impacts downstream phase success because unclear baselines create rework, delays, and inconsistent builds. EVT is where teams should move from “it works” to “it’s defined, reproducible, and reviewable,” so decisions can carry forward without tribal knowledge. The best EVT packages make it easy to compare lots, isolate variables, and prove fixes with minimal back-and-forth.

What is EVT in an LCD display module project, and why do documents matter?

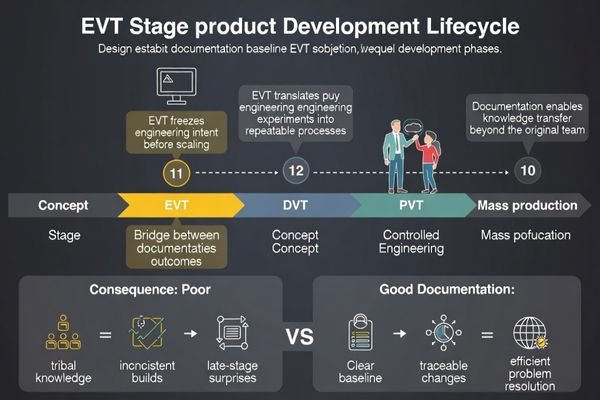

EVT represents the engineering validation phase proving design functionality before production scaling, with documentation enabling repeatability and knowledge transfer.

EVT proves the design works as an engineering solution before scaling. Documents matter because they freeze what was built, how it was tested, and what limits were found—so issues can be traced to design variables, fixes can be reverified across builds, and DVT can start from a clear baseline instead of guesswork.

EVT is the bridge from concept to controlled engineering reality, and it typically precedes DVT (design maturity) and PVT (production validation). For LCD display modules, EVT is not only “does it light up,” but whether timing, power/backlight behavior, optical performance, mechanical stack-up, and reliability margins are consistent under defined conditions. Without explicit documentation, teams cannot reproduce the same build or the same test state, which leads to late-stage surprises and uncontrolled changes.

EVT Design Validation Scope

EVT should document the full scope being validated—electrical, optical, mechanical, and reliability—tied to acceptance criteria. This includes the test conditions that strongly affect results: temperature, brightness/dimming state, test patterns, measurement geometry, and any special configuration required to reach the tested state. If the validation scope is not written, downstream teams will unintentionally change conditions and invalidate comparisons.

Documentation Impact on Project Continuity

Strong EVT documentation2 turns results into durable design knowledge that survives team changes and schedule pressure. It enables clean comparisons between sample lots, makes root-cause work faster, and reduces DVT churn by preventing re-discovery of known constraints. Most importantly, it provides a controlled baseline so future changes can be evaluated against a stable reference.

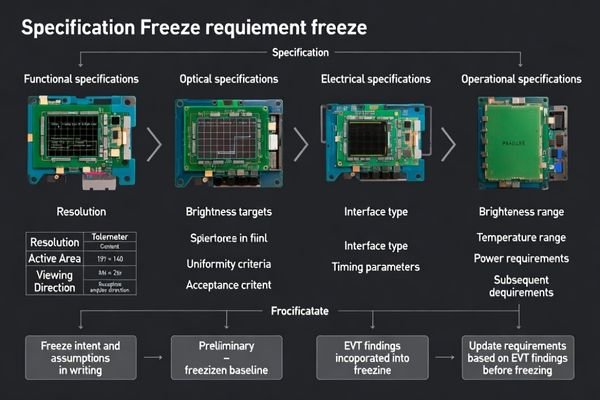

Which engineering specifications must be frozen or updated at EVT?

EVT requires freezing critical specifications defining module functionality and expected behavior while updating requirements based on validation findings.

Freeze the documents that define “what you built” and “how it should behave”: the module functional spec plus interface, power, and backlight expectations. Update them using EVT findings so DVT starts from corrected requirements, not tribal knowledge—especially for timing, sequencing, optical targets, and operating limits.

At EVT, the core is locking intent and assumptions in writing. Functional specifications3 should cover resolution/active area, viewing direction, brightness targets under defined conditions, acceptable uniformity or mura criteria, operating temperature ranges, and key optical stack assumptions. Electrical specifications should define interface type and mapping expectations, timing parameters and margins, power rails and sequencing, backlight control method and dimming ranges, and protection expectations for EMI/ESD as engineering targets. EVT should also incorporate corrections discovered during validation so the “frozen” baseline is accurate.

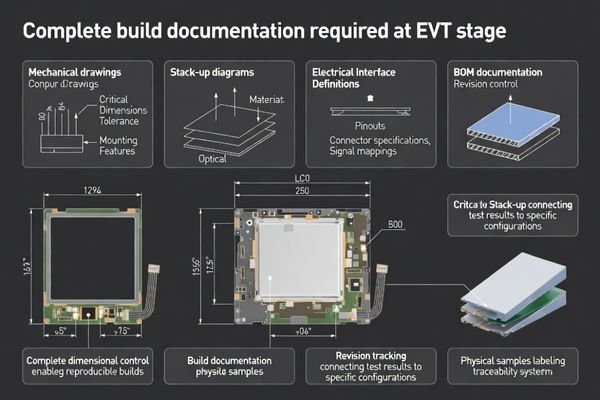

What drawings and build documents are required to make EVT repeatable?

EVT requires complete physical and electrical build definitions enabling sample reproduction and build variation explanation.

Deliver controlled build definitions so the same module can be reproduced: mechanical drawings (outline, active area, mounting, connector), stack-up and tolerances tied to fit/optics, and electrical pin/interface definitions. Include BOM and revision control plus traceability rules so every test result can be linked to a specific build version.

Repeatability depends on controlling the physical and electrical reality of what was tested. Mechanical deliverables should include outline, active area, bezel/cover lens stack, mounting features, connector location, and keep-out zones, plus a stack-up definition that links tolerances to fit and optical performance4. Electrical deliverables should include pin definitions, interface mapping assumptions, and any required strap/configuration states. The build package should also include BOM with revision control, approved material definitions for key optical parts, and labeling/traceability rules that connect EVT data to build revisions and sample serials.

| Document Category | Critical Elements | EVT Requirements |

|---|---|---|

| Mechanical Drawings | Outline, active area, mounting features | Controlled dimensions with tolerances |

| Stack-up Definition | Layer materials and thicknesses | Tied to optical and fit performance |

| Electrical Interface | Pin assignments and timing | Complete mapping and configuration |

| BOM Control | Part numbers and revisions | Traceability to test results |

Comprehensive build documentation enables EVT data correlation to specific build configurations, supporting systematic problem resolution and ensuring downstream phase consistency.

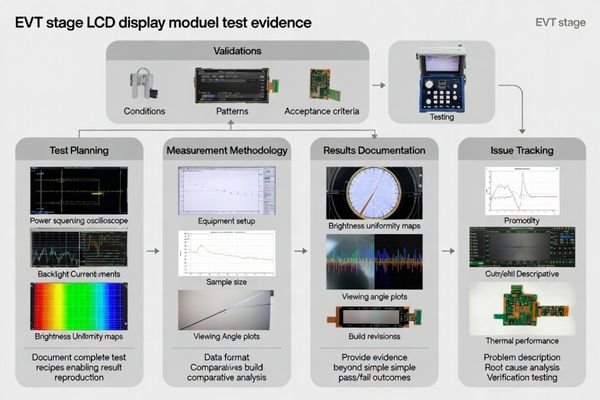

What validation reports and test evidence should be included in EVT deliverables?

EVT deliverables require comprehensive test evidence enabling result reproduction and margin understanding beyond simple pass/fail outcomes.

Include test reports that others can rerun: test recipes (conditions, patterns, geometry), instruments, sample size, acceptance criteria, and results with evidence. For LCD modules, attach power/sequencing observations, backlight current/protection behavior, brightness and uniformity maps, viewing-angle checks, plus an issue log with retest outcomes linked to build revisions.

EVT reports5 should provide margin understanding, not just pass/fail. Define test conditions (temperature, brightness state, patterns, measurement geometry), instruments used, sample size, and acceptance criteria. Provide evidence such as traces, captures, photos, or measurement maps where relevant. Typical LCD module EVT evidence includes power rail and sequencing observations, backlight current behavior and protection events, brightness and uniformity mapping under defined states, viewing-angle checks, and basic EMI/ESD risk observations tied to integration assumptions. A consolidated issue log should capture symptoms, conditions, suspected causes, corrective actions, and retest outcomes so DVT does not repeat EVT learning. For comprehensive EVT documentation development and validation report optimization during complex LCD module engineering validation requiring systematic evidence collection, engineering teams can contact info@lcdmodulepro.com when documentation requirements demand specialized expertise in validation planning and test evidence organization.

Test Evidence Documentation

Test evidence should include the exact recipe needed to reproduce the result: configuration state, pattern set, brightness/dimming mode, temperature stabilization method, viewing direction, and measurement geometry. Results should be recorded in a form that supports comparison across builds (consistent units, consistent sampling points, consistent filenames/IDs). Without recipe-level detail, differences across labs or builds become unresolvable.

Issue Tracking and Resolution

An EVT issue log should be treated as a deliverable, not an internal note. It should link each issue to build revision and sample ID, document decision points, and include retest evidence after fixes. This prevents “tribal knowledge” and provides a clean handoff into DVT risk management.

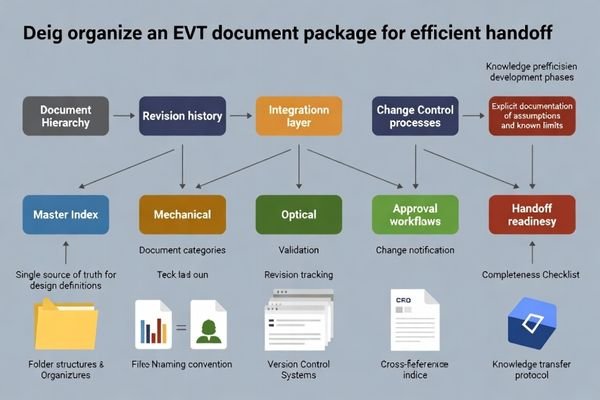

How do you define an EVT document package that supports handoff and customization?

EVT document packages require structured organization enabling efficient handoff while supporting customization requirements and change control.

Build a handoff-ready package with a single source of truth: revision control, change log, and documents grouped by layer (mechanical, optical, electrical, power/backlight, validation). Explicitly record assumptions and known limits found in EVT, and tie every report to build revisions and test recipes—especially critical for custom modules.

A strong EVT package is organized for handoff readiness: another engineer should be able to rebuild, retest, and integrate with minimal back-and-forth. Start with a single source of truth for revisions and a clear change log, then group documents by integration layer: mechanical stack and mounting constraints, optical targets and measurement recipes, electrical interface and timing expectations, power/backlight control and protection behavior, and validation reports with issue tracking. Include explicit assumptions and “known limits” discovered during EVT so downstream teams do not unknowingly operate outside validated conditions. For application-specific projects, customization documentation should also capture agreed acceptance criteria and how variability will be controlled across batches and lifecycle.

EVT Document Package Framework:

- Revision Control and Change Management: Establish single source of truth for document versions with comprehensive change log tracking design evolution, implement controlled revision numbering linking documentation to specific build versions, define change approval process6 ensuring design modifications are systematically reviewed and documented, maintain traceability between document updates and validation results enabling correlation analysis

- Integration Layer Organization: Group mechanical documents including drawings, stack-up definitions, mounting constraints, and tolerance analysis, organize optical specifications including brightness targets, uniformity criteria, viewing angle requirements, and measurement procedures, compile electrical documentation including interface definitions, timing parameters, power requirements, and protection specifications, consolidate validation evidence including test reports, issue logs, and acceptance criteria verification

- Assumption and Limitation Documentation: Document explicit design assumptions discovered during EVT validation, identify known operational limits and environmental constraints requiring downstream attention, define acceptance criteria and measurement procedures enabling consistent evaluation, establish variability control strategies for custom applications requiring batch consistency

- Handoff Readiness Verification: Ensure documentation completeness enabling independent module rebuild and integration, validate test procedure reproducibility through independent execution, confirm change control processes support future design evolution, verify knowledge transfer completeness through structured review and handoff validation

FAQ

Should EVT documents be different for standard modules versus custom modules?

The structure is similar, but custom projects typically require tighter control of drawings, stack-ups, acceptance criteria, and change logs because small differences can impact optical and reliability outcomes.

What is the minimum "must-have" EVT document set?

A controlled specification, mechanical drawing/stack-up, interface and power definition, BOM with revision control, test plan with conditions, and an EVT report with issue log and retest results.

How do you prevent EVT results from becoming "tribal knowledge"?

Use explicit test recipes, link every result to a build revision/serial, maintain an issue tracker with decisions, and freeze key assumptions as written requirements.

Do I need optical measurement reports at EVT if the UI is simple?

Yes, because brightness, uniformity, and viewing-angle behavior affect readability and reliability, and they can drift with thermal and mechanical changes even for simple content.

What should be included in the EVT issue log?

Symptoms, conditions, affected build versions, suspected causes, corrective actions, retest evidence, and any remaining risks carried into DVT.

When is EVT "complete" from a documentation standpoint?

When the build is reproducible, acceptance criteria are defined, key risks are documented with evidence, and the handoff package supports DVT planning without gaps.

Conclusion

EVT document deliverables transform engineering validation into repeatable, reviewable baselines for LCD display module projects by systematically freezing design definitions, test procedures, and validation evidence while establishing controlled handoff processes for subsequent development phases. Effective EVT documentation combines controlled specifications, complete build definitions, comprehensive validation reports, and structured change management enabling smooth transitions from engineering validation through production planning. Strong EVT packages prevent late-stage surprises and reduce development iteration cycles by establishing clear design baselines with explicit assumptions, acceptance criteria, and issue tracking supporting systematic problem resolution.

MEIDAYINGNUO provides comprehensive EVT documentation and validation services for LCD display module projects requiring systematic engineering validation support, including specification development, test plan creation, validation report preparation, and structured handoff package organization for complex custom applications. Our engineering team offers specialized expertise in EVT documentation framework development, change control implementation, and validation evidence organization ensuring smooth project transitions from engineering validation through production phases while maintaining design knowledge continuity and supporting long-term product lifecycle management. Contact our technical specialists when EVT documentation requirements demand systematic validation planning and comprehensive handoff package development.

✉️ info@lcdmodulepro.com

🌐 https://lcdmodulepro.com/

-

Understanding EVT documentation quality can help improve project outcomes and reduce rework in integration processes. ↩

-

Exploring this resource will help you understand how EVT documentation ensures project continuity and reduces risks. ↩

-

Understanding Functional specifications is crucial for ensuring product quality and meeting engineering standards. ↩

-

Exploring the impact of optical performance on design can enhance product quality and user experience, making it a vital area of study. ↩

-

Understanding EVT reports is crucial for effective engineering validation, ensuring comprehensive documentation and evidence collection. ↩

-

Understanding the change approval process is crucial for effective project management and ensuring systematic design modifications. ↩