Effective brightness procurement requires measurable, repeatable terms that lock test conditions and acceptance rules—not just a single nit number. When “brightness” is defined like a contract test, both sides can evaluate lots consistently and avoid disputes caused by different patterns, dimming settings, geometry, or optical stacks.

Brightness is only enforceable in procurement when test conditions are locked. Define what is measured (luminance at the display surface), the operating mode (backlight and dimming settings, test pattern), the measurement setup (geometry and ambient), and the lot acceptance rule. Without these, the same module can “pass” and “fail” depending on how it is tested.

Brightness disputes usually happen when procurement terms leave room for interpretation. If a supplier measures full-white at one backlight setting and the buyer measures a window pattern with different dimming or warm-up, both results may be “correct” yet incompatible for acceptance decisions.

A procurement-ready brightness spec translates user readability expectations into controlled measurement conditions, clear acceptance thresholds1, and a defined dispute process. The goal is simple: the same sample measured under the agreed method should produce the same pass/fail result, regardless of who performs the test.

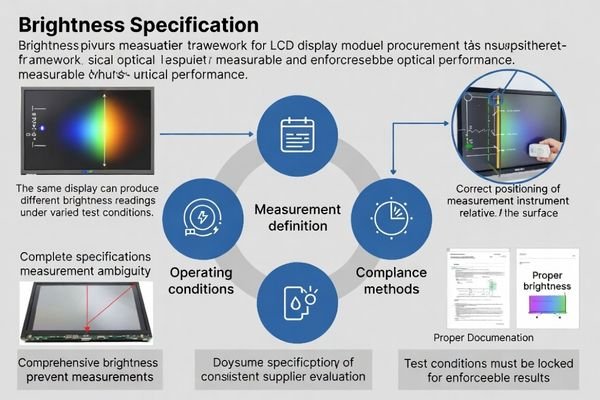

What does "brightness" mean in procurement terms?

Brightness in procurement must be defined as measurable optical performance under controlled operating conditions rather than marketing specifications or theoretical maximums.

In procurement, brightness must be a measurable outcome under controlled conditions, not a marketing value. For LCD display modules, define the measured quantity (luminance at the display surface), the operating mode (backlight setting, dimming state, test pattern), and the measurement environment (geometry and ambient). A nit value without these anchors is not a contract term.

Brightness readings can vary widely with pattern choice, drive settings, measurement geometry, and optical stack conditions. A strong definition prevents “spec gaming” by making the measurement comparable across suppliers and lots, and by aligning the number to the user experience you are actually buying.

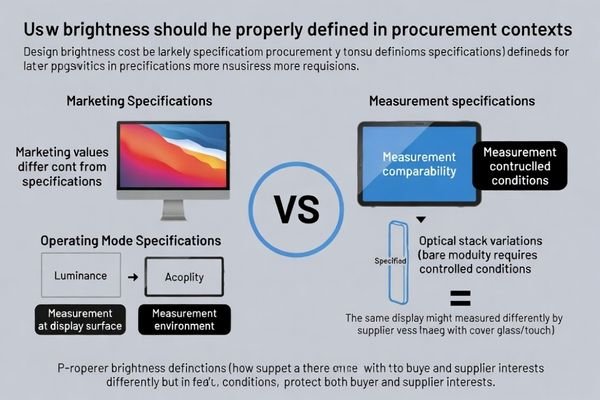

Measurable Performance Definition

Procurement brightness specifications2 should define luminance at the display surface under controlled conditions, and clearly state whether the requirement applies to the module alone or to an integrated stack that includes a cover lens, bonding, or touch. This avoids mixing “module capability” with “system optical loss” in a single ambiguous term.

Operating Condition Control

Effective brightness terms lock the backlight drive setting, test pattern, dimming state, and thermal conditions used for measurement. These constraints make the result repeatable and meaningful, rather than a best-case peak value that does not represent real operation.

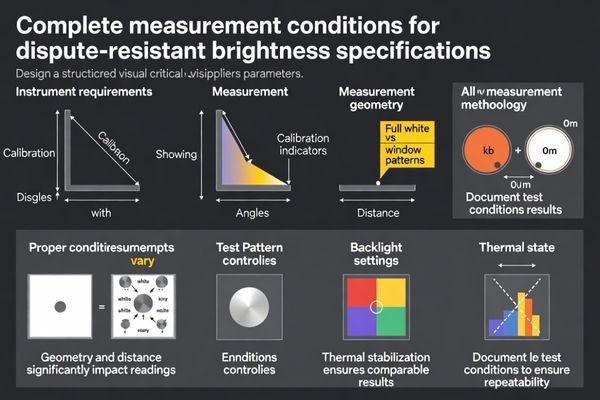

Which measurement conditions must be specified to avoid disputes?

Dispute-resistant brightness terms require comprehensive specification of measurement setup, operating conditions, and thermal state to ensure repeatable results.

To prevent disputes, lock the setup and operating point: instrument type and calibration status, on-axis geometry and distance/FOV, the exact test pattern (full white vs window size), backlight drive condition (current or PWM duty/frequency), and thermal state (warm-up time and stabilized temperature). Also state whether acceptance applies to the bare module or the integrated stack.

Clear measurement conditions turn brightness from a subjective perception into a controlled comparison3. They also make it easier to diagnose disagreements: if supplier results differ from buyer results, the first checks are pattern, dimming settings, geometry, and warm-up/temperature—not arguments over intent.

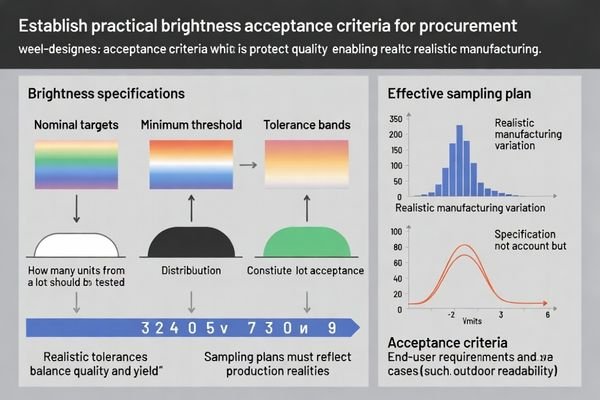

How should you set acceptance criteria and tolerances for brightness?

Practical brightness acceptance requires nominal targets, tolerance bands, and sampling plans balancing clarity with manufacturing reality and yield considerations.

A usable clause defines a nominal target, a minimum shipment threshold, and a tolerance band—plus a sampling plan and lot disposition rule. Don’t rely on “≥ X nits” alone. Specify how many units are tested per lot, what pass/fail means for the lot, and how measurement uncertainty is handled. Separate typical intent from minimum acceptance to avoid yield-driven disputes.

Tie acceptance logic to the real use case. If the product must be sunlight-readable, define brightness in the same optical configuration and ambient assumptions the end user will see. Otherwise, you risk paying for unnecessary headroom—or rejecting acceptable lots because the acceptance test4 does not match the intended operating mode.

| Acceptance Parameter | Specification Requirement | Implementation Guidance |

|---|---|---|

| Nominal Target | Design intent brightness level | Representative of typical production capability |

| Minimum Threshold | Shipment acceptance floor | Accounts for manufacturing variation and yield |

| Tolerance Band | Allowable variation range | Balances quality control with production feasibility |

| Sampling Plan | Lot acceptance criteria | Defines test quantity and pass/fail decision rules |

Use this table as a template for writing terms that are both fair and enforceable. If uniformity affects usability, define it as a separate clause (e.g., center-to-corner limits) rather than letting it silently confuse the brightness requirement.

What supporting documents make brightness terms enforceable in contracts?

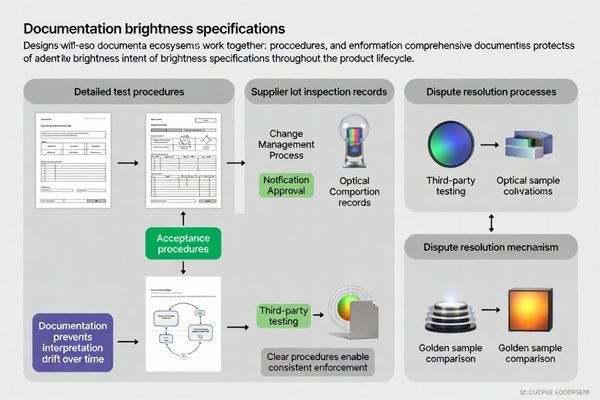

Enforceable brightness terms require comprehensive supporting documentation including test procedures, inspection records, and dispute resolution processes.

Brightness becomes contract-enforceable when paired with shared documents: a test procedure (equipment, setup, warm-up, pattern, reporting), supplier lot inspection records, and a defined dispute path (re-test method, third-party lab option, or agreed reference setup/golden sample). Lock the acceptance mode if multiple brightness modes exist, and require change notification for any backlight or optical-stack change.

These supporting documents prevent “numeric compliance5” from drifting away from the intended user experience over time. They also protect both parties by making responsibility boundaries explicit: what the supplier must control and report, what the buyer will verify, and how disagreements are resolved consistently.

Test Procedure Documentation

Test procedures should define instrument requirements (with traceable calibration), setup parameters, warm-up protocols, test patterns, measurement geometry, ambient conditions, and the reporting format. A good procedure makes it difficult to accidentally measure a different “brightness” than the one being purchased.

Quality Control and Lifecycle Management

Lot inspection records, change notification rules, and a dispute-resolution process keep the term enforceable throughout the lifecycle. If backlight LEDs, diffuser films, light guides, drivers, or optical stack materials change, the contract should require notification and define whether re-qualification is needed.

How do you write a procurement-ready brightness clause template?

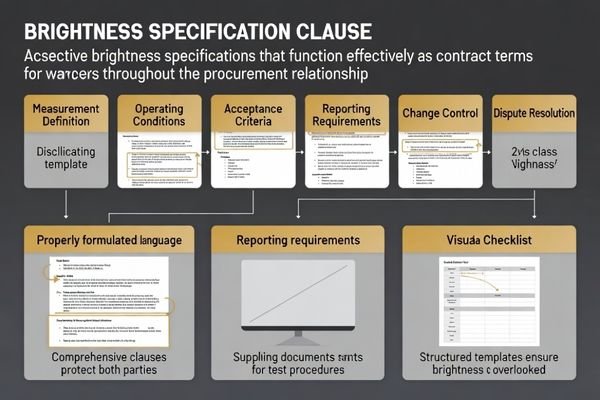

Procurement-ready brightness clauses require structured templates defining measurement objects, operating conditions, acceptance rules, and change control procedures.

A procurement-ready brightness clause reads like a testable agreement. Define the measurement object (module-only or integrated stack), operating conditions (backlight drive, dimming method, pattern), measurement setup (geometry, instrument and ambient), and acceptance rules (nominal, minimum, tolerance band, sampling, lot disposition). Add required report fields, re-test authority, and change-control triggers for backlight/optical-stack modifications.

This structure protects both sides: suppliers know exactly how they will be evaluated, and buyers receive brightness performance that matches real usability rather than an isolated lab number. Values shown below are placeholders to be filled per project requirement and agreed test conditions.

Core Specification Elements

Measurement Definition:

Brightness shall be measured as luminance (cd/m², nits) at the display surface using a calibrated luminance meter (traceable calibration, defined accuracy) positioned on-axis at 50cm distance with a defined measurement field of view under controlled ambient lighting (<1 lux).

Operating Conditions:

Measurement shall be performed with module at nominal backlight drive current (XXX mA), using full-white test pattern (255,255,255 RGB), after 30-minute warm-up period, with PWM dimming disabled or at 100% duty cycle.

Acceptance Criteria6:

Nominal brightness target: XXX cd/m² ±10%

Minimum acceptance threshold: XXX cd/m²

Sampling plan: 5 units per production lot

Lot acceptance: ≥4 units must meet minimum threshold

Compliance and Control Framework

Reporting Requirements:

- Measurement data including individual readings, average, standard deviation, and pass/fail status

- Test conditions verification including equipment calibration status and environmental parameters

- Lot traceability information linking brightness results to specific production batches

- Deviation reporting for any units failing acceptance criteria with root cause analysis

Change Control Procedures:

- Notification requirement for any backlight component, diffuser, or optical stack modifications

- Re-qualification trigger conditions requiring brightness validation after design changes

- Approval process for substitutions or alternates affecting optical performance

- Documentation updates ensuring specification alignment with modified configurations

Dispute Resolution Process:

- Re-test procedures using agreed equipment and conditions for measurement conflicts

- Third-party laboratory option for independent verification when internal results disagree

- Golden sample or agreed reference setup enabling standardized comparison for borderline cases

- Escalation authority and timeline for resolving acceptance disputes efficiently

FAQ

Should brightness be specified as "typical" or "minimum" in procurement?

Use both: a typical target for design intent and a minimum acceptance threshold for shipment, paired with a sampling plan so the requirement is realistic and enforceable.

Do I need to specify the test pattern (full white vs window)?

Yes—different patterns change average power and optical behavior; specifying the pattern prevents two parties from measuring different "brightness."

Should brightness be measured on the bare module or with the cover lens/touch stack?

It depends on what you are buying; for user experience, measure the integrated stack, but keep a module-only control measurement to manage supplier responsibility and troubleshooting.

How do we handle measurement uncertainty and instrument differences?

Define instrument class/accuracy, calibration status, geometry, and a re-test procedure; consider a third-party lab or agreed reference setup for disputes.

Can PWM dimming settings affect brightness acceptance?

Yes—PWM duty/frequency and driver configuration can change measured output and perception; lock the dimming method and settings in the acceptance condition.

What changes should trigger brightness re-qualification?

Backlight LEDs, diffuser films, light guide, driver changes, and any optical stack modifications should trigger notification and evaluation because they can shift brightness and uniformity.

Conclusion

Brightness procurement terms work only when they are measurable, repeatable, and tied to the real operating mode and optical stack you will ship. By locking measurement conditions, defining acceptance logic (including sampling and lot disposition), requiring clear reports, setting a dispute process, and enforcing change control, buyers avoid “numbers that pass but products that fail,” and suppliers get a clear, fair target. For LCD display module purchasing, the best clause is the one that aligns lab measurements with real readability in the intended environment.

MEIDAYINGNUO provides LCD display module procurement support for brightness specifications, including clause template development, test method alignment, acceptance and sampling logic, dispute re-test frameworks, and change-control triggers to keep brightness performance consistent across lots and lifecycle changes.

✉️ info@lcdmodulepro.com

🌐 https://lcdmodulepro.com/

-

Exploring this topic will help clarify how to set clear standards for product acceptance, reducing disputes. ↩

-

Understanding brightness specifications is crucial for ensuring consistent display quality and performance across different suppliers. ↩

-

Exploring controlled comparison methods can provide insights into achieving reliable and objective measurement results. ↩

-

Learn about effective acceptance testing methods to ensure your products meet quality standards and specifications. ↩

-

Understanding numeric compliance is crucial for maintaining user experience standards and ensuring product quality. ↩

-

Learn about acceptance criteria to understand how products are evaluated for quality and performance standards. ↩