Align requirements and constraints early to prevent late rework.

- Application & environment

- Size & mechanical envelope

- Brightness & power budget

- Interfaces & project stage

We help equipment manufacturers develop custom industrial LCD modules that are special-shaped, high-brightness, and integration-ready. From mechanical feasibility and optical performance to interface compatibility and long-term reliability, our engineering team reduces project risk early and supports stable delivery from prototype through production.

Industrial display projects often fail not because of the LCD panel itself, butbecause engineering risks are discovered too late.Our role is to identify and solve these risks early.

When standard displays don’t fit your product design:

We deliver:

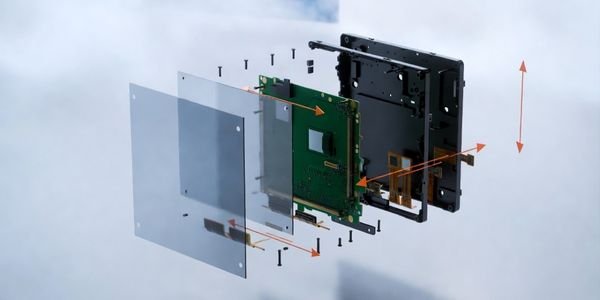

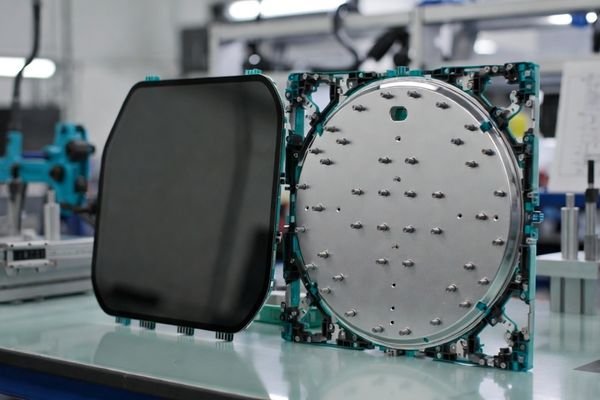

We evaluate mechanical feasibility, active area redesign,backlight re-configuration, and assembly structure tomake sure your special-shaped LCD module can truly bebuilt and integrated.

When visibility and lifetime both matter:

We deliver:

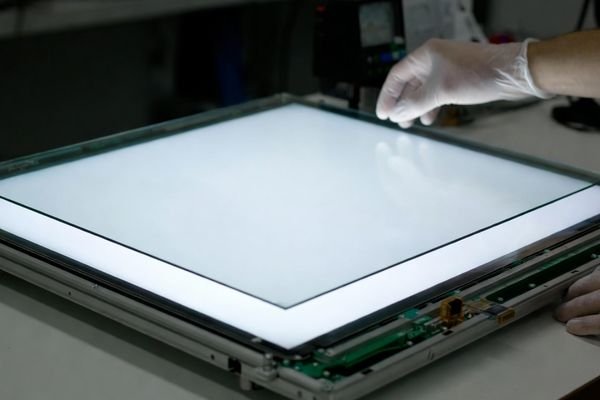

We engineer high-brightness backlight systems, opticalbonding structures, and thermal solutions to achieveindustrial-grade visibility with stable performance.

When the display must work reliably inside a real system:

We deliver:

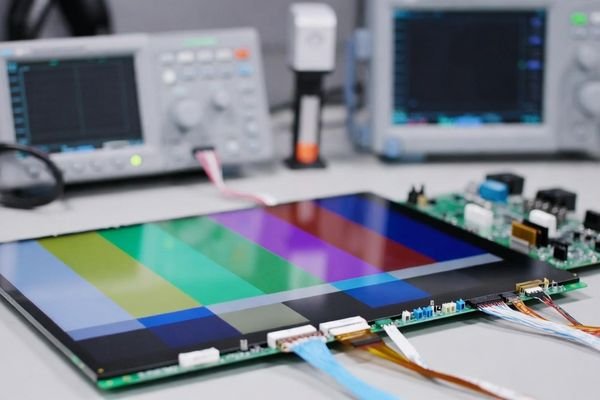

We help ensure your LCD module fits your electronicsplatform and works consistently.

When the module must fit into your housing:

We deliver:

We design LCD modules as part of your product, not asisolated components.

When your product must work long-term in real

Principle:

Reliability is engineered into the solution, not assumed

Engineering capability matters only when it reduces integration surprises and keeps performance stable beyondsamples.

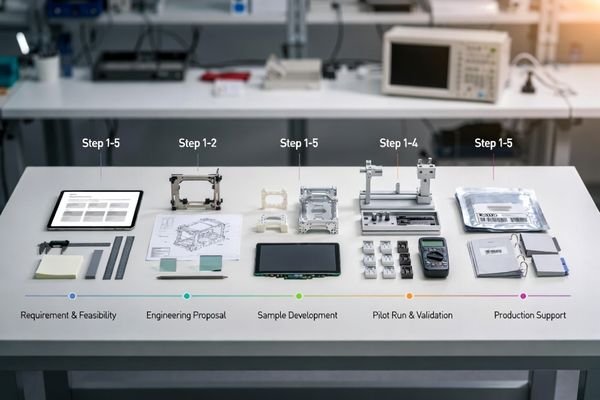

Our engineering process is designed to reduce uncertainty and support long-term industrial projects.

Align requirements and constraints early to prevent late rework.

Propose a verified approach with risks, mitigations, and clear alternatives.

Build and iterate prototypes to confirm performance and integration assumptions.

Run a pilot build to validate consistency and system-level behavior.

Support production with stable builds, change control, and long-term continuity.

We operate as an engineering-driven solution provider supported by a qualified manufacturing ecosystem. This system keeps engineering flexible while maintaining production reliability across sourcing, manufacturing control, quality coordination, and long-term supply planning.

We work with a controlled manufacturing network covering the processes required for industrial LCD module delivery.

Manufacturing is managed as part of the engineering process—checkpoints, traceable changes, measurable outcomes.

An engineering-integrated supply system designed to reduce uncertainty from prototype through mass production.

Engineering-driven industrial LCD module solution provider, secured by a controlled manufacturing ecosystem.

An engineering-driven approach helps equipment manufacturers achieve measurable outcomes in development, integration, and long-term performance.

Risks are often discovered late, when changes are expensive and schedules are already committed.

Engineering makes the project clearer, safer, and more controllable by validating critical risks early.

We focus on engineering not to make projects complex, but to make them clearer, safer, and more controllable.

Share your target display size, expected resolution/interface, brightness target, environment (indoor/outdoor), mounting constraints, and your current project stage. A simple sketch or enclosure outline is very helpful.

Yes. We typically start by confirming the active area, corner radius/cutouts, bezel limits, and mechanical tolerance stack-up, then align on feasible tooling and validation steps.

It depends on viewing conditions. We align on your ambient light and viewing distance, then propose a target luminance range and verify readability with a practical acceptance method.

Outdoor-facing designs usually require stronger optical control (reflection management), thermal strategy (sun load), ingress protection expectations, and long-term stability considerations.

The key items are mechanical envelope, connector orientation and strain relief, cable routing, heat dissipation path, mounting points, and serviceability. Confirming these early avoids late redesign.

Yes. We can review your enclosure and mounting concept, identify risk items (warpage, stress points, tolerance risks), and propose a verification plan that can be executed with early prototypes.

We usually go from requirement definition → feasibility and risk review → sample/prototype → integration validation → pilot build → acceptance criteria sign-off. The goal is predictable performance before scaling.

We confirm your source output, timing requirements, cable length, and EMI constraints, then lock a compatible baseline configuration and define how it will be verified during integration tests.

If your project involves:

We invite you to start an engineering-level discussion.

Tell us about your application, size expectations, brightness requirements, and current project stage.

We will contact you within 1 working day, please pay attention to the email with the suffix “@lcdmodulepro.com”.