LCDModulePro supports equipment manufacturers with non-standard, special-shaped, and application-specific LCD modules—where catalog parts are not enough. We work as a project-oriented solution partner, helping teams move from requirements to stable, long-term supply.

This positioning allows us to participate in development discussions, adapt solutions tospecific equipment, and remain involved beyond the sample stage.

Our focus is not transactional supply, but longer-term projectcooperation.

We engage early in requirement alignment and riskidentification-before decisions harden into rework.

We adapt mechanics, interfaces, and integrationconstraints to fit the realities of your device platform.

We scale delivery through a managed network withconsistent process control and quality expectations.

We translate requirements into measurable acceptancecriteria to reduce sample-stage uncertainty.

We stay involved through iteration, ramp-up, andchange control-not only at the sample handoff.

We prioritize milestone-based collaboration overtransactional supply, with ongoing technical support.

We deliberately focus on projects where engineering involvement changes outcomes.

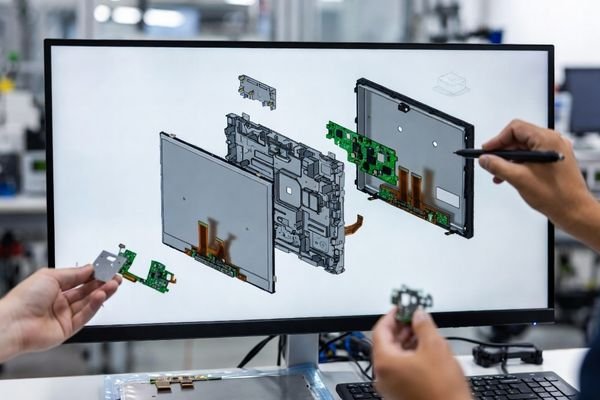

Display form factors, mounting, I/O, or stack-up require custom integration decisions.

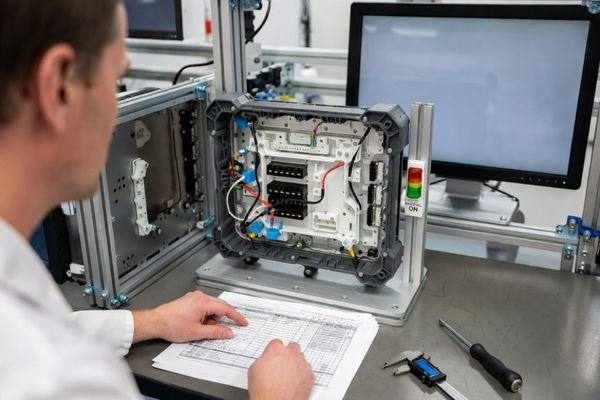

Thermal, vibration, sealing, EMC, and space limits drive engineering trade-offs.

Projects require consistency over time: lifecycle control, reliability, and steady performance.

The display module impacts mechanical layout, electronics, UI, and overall product constraints.

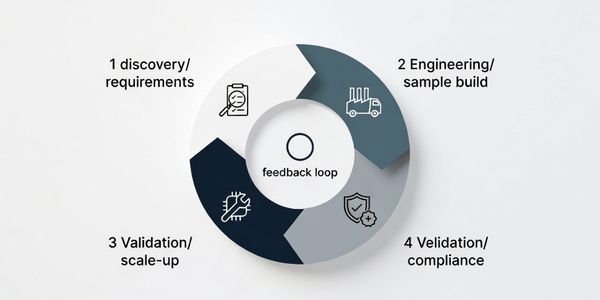

A gated engagement flow that keeps scope, checkpoints, and “done” criteria clear from alignment through pilot handover.

Align context, constraints, and success criteria before work begins.

Turn scope into a plan with risks, owners, and clear gates.

Validate against agreed checkpoints, then iterate with change control.

Pilot for repeatability, then hand over what’s locked and verified.

We work best with organizations that bring clear equipment context and treat the display module as part of the product system—so decisions can be evaluated, integrated, and carried forward beyond prototypes.

Projects with real equipment context and integration constraints.

A technical owner who can define, review, and verify requirements.

Decisions impact structure, usability, and long-term reliability.

A clear path from samples to stable, repeatable supply.

We set clear boundaries to keep delivery predictable and cooperation efficient—so projects stay focused, verifiable, and execution-ready.

We operate around project scoping and integration, so retail-style fulfillment is not our model.

Without equipment context, pricing alone cannot define feasibility, risk, or what “done” means.

We need the device environment, interfaces, and constraints to evaluate integration and stability.

If continuity after prototypes is not planned, we cannot ensure consistent supply and outcomes.

Integration decisions need verification time; skipping validation increases rework and supply risk later.

If key constraints cannot be shared, we can’t scope feasibility or align on acceptance expectations.

Our objective is practical and consistent: to participate in industrial equipment projects as a reliable display engineering partner, supporting solutions that can be developed, integrated, and sustained.

Move from requirements to prototype with verifiable checkpoints, so the solution can be built and accepted.

Fit real equipment context—interfaces, mechanics, and workflow—reducing integration risk and rework.

Support long-term consistency with stable supply, controlled changes, and maintainable delivery.

If your project involves specialized equipment, non-standard displays, or long-term product development, we welcome a discussion.

Tell us about your equipment context and project stage.

📧 Email: info@lcdmodulepro.com

📞 Phone/WhatsApp: +86 18971642327

📍 Address: Shenzhen, Guangdong, China

We will contact you within 1 working day, please pay attention to the email with the suffix “@lcdmodulepro.com”.