Systematic backlight flicker troubleshooting requires identifying whether the issue stems from power instability, driver configuration problems, or system integration factors affecting LED current regulation.

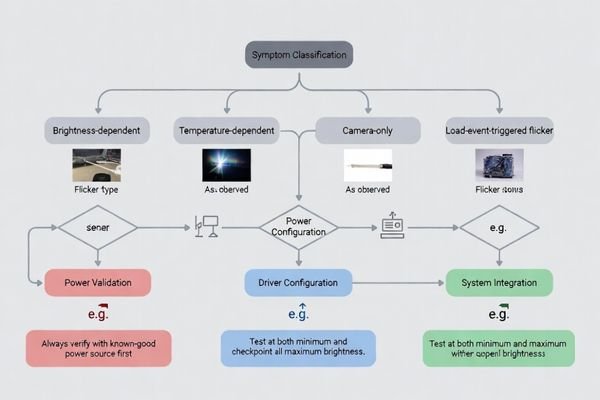

To troubleshoot a flickering backlight quickly, first classify the symptom (camera-only vs visible to the eye, brightness-dependent vs present at 100%, temperature-dependent vs immediate, load-event-triggered vs steady). Then isolate the power path with a known-good supply and fixed brightness, measure input rail stability and LED current ripple, and finally verify grounding/layout and harness conditions to confirm a repeatable root cause before changing multiple parameters at once.

In LCD display module integration work at MEIDAYINGNUO, backlight flicker1 is frequently driven by system-level integration conditions rather than simple component failure. When you connect the flicker behavior to power events, dimming settings, thermal rise, and grounding/harness conditions, you can converge faster on a stable, production-repeatable fix without unnecessary part substitution.

What are the most common root causes of backlight flicker?

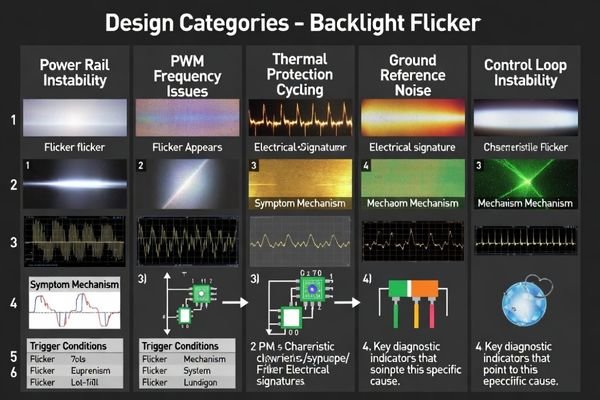

Backlight flicker typically originates from power path instability rather than LCD pixel interface problems, with specific failure modes that can be systematically identified.

Common backlight flicker causes include PWM dimming interactions with driver topology, insufficient power rail headroom forcing driver dropout, poorly controlled inrush behavior causing current regulation oscillation, grounding and return path issues injecting noise into LED current sense loops, thermal protection cycling, and control loop compensation mismatches when LED string characteristics differ from driver expectations.

Backlight flicker diagnosis becomes efficient when you correlate the symptom with system conditions. Flicker that tracks brightness settings suggests PWM modulation2 choices or current-regulation behavior, while flicker correlated with temperature rise or supply voltage points to margin limitations or protection behavior. Establishing these correlations early prevents chasing multiple “possible fixes” without proving the mechanism.

Power Supply Related Issues

Input voltage instability, insufficient headroom, and supply transients can push LED drivers into dropout or protection modes that manifest as visible brightness fluctuation.

Driver Configuration Problems

Incorrect PWM frequency selection, inappropriate current limits, and control loop compensation mismatches create regulation instability that appears as flicker under specific operating conditions.

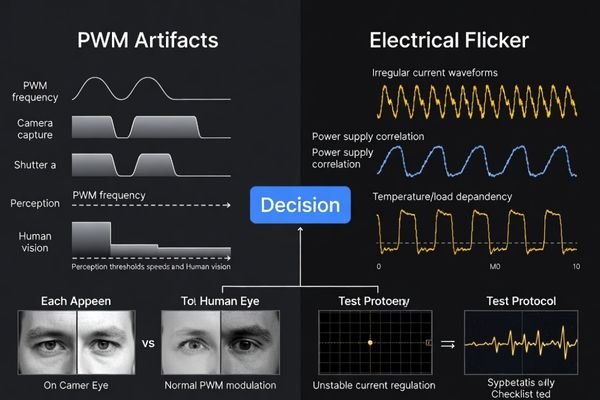

How do you distinguish "PWM artifact" from real electrical flicker?

Separating perception effects from actual LED current instability requires systematic testing across different viewing conditions and measurement techniques.

Distinguish PWM artifacts from electrical flicker by testing visibility across different observers and camera settings, varying dimming mode between PWM and analog if available, adjusting PWM frequency, and testing at multiple brightness points. Real electrical flicker persists across dimming methods and often correlates with supply voltage, temperature, or load changes rather than modulation parameters.

A useful working definition is: PWM artifact is a sampling/perception interaction, while electrical flicker3 is LED current instability. PWM artifacts often become most noticeable at low brightness where duty cycles are small and the modulation falls into sensitive ranges for cameras or human perception. Electrical instability tends to remain present across different viewing conditions and is more likely to change with rail headroom, thermal drift, or load transients than with camera shutter settings.

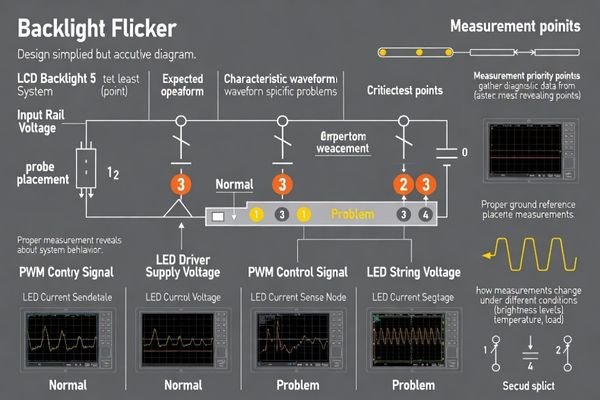

Which quick measurements isolate power, driver, and load problems?

Specific measurement points enable rapid isolation of backlight flicker root causes by examining power supply stability, driver behavior, and load interactions.

Key measurements include input rail stability during brightness changes and load transients, LED string voltage monitoring, and LED current ripple analysis under different brightness conditions. Check for input voltage droop that crosses undervoltage thresholds, compare current waveforms at low versus high brightness, and examine sense node noise relative to driver ground reference to identify regulation loop contamination.

Thermal correlation testing often reveals margin problems that only appear after temperature rise. Running steady brightness until thermal equilibrium and observing whether flicker appears after heating helps identify thermal foldback behavior, component drift, or marginal headroom that is acceptable when cold but unstable when warm.

| Measurement Point | Diagnostic Purpose | Failure Indicators |

|---|---|---|

| Input Rail Stability | Power supply adequacy | Voltage droop, transients during load changes |

| LED Current Waveform | Regulation loop stability | Low-frequency ripple, periodic on/off behavior |

| Sense Node Reference | Grounding integrity | Noise injection, ground bounce effects |

Systematic measurement correlation with operating conditions enables rapid identification of specific failure mechanisms affecting backlight stability4.

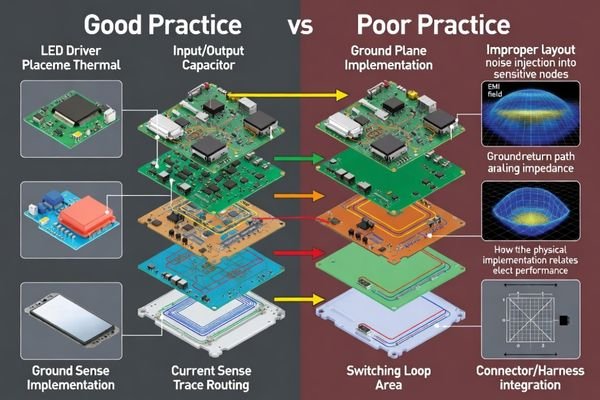

What layout and grounding issues can create flicker even with a "good" driver?

Poor layout and grounding implementation can destabilize LED driver control loops and create flicker symptoms even with properly specified components.

Layout issues affecting backlight stability include long or shared return paths between LED current sense and switching nodes, poor input/output capacitor placement, excessive switching loop area, routing sense traces near high dV/dt nodes, and mechanical integration factors such as long harnesses, loose connectors, or variable chassis grounding that creates intermittent resistance and ground reference shifts.

Even robust LED drivers5 can become unstable when the sense loop integrity is compromised by switching noise or ground impedance variation. Treat the backlight circuit as a high-current, noise-sensitive subsystem: keep sense routing tight and protected, control the switching loop area, and ensure the grounding approach gives the sense reference a clean, stable baseline. For comprehensive backlight system design review and stability analysis, engineering teams can contact info@lcdmodulepro.com during integration planning.

Control Loop Contamination

Switching noise injection into current sense paths can cause false regulation responses that manifest as brightness fluctuation even when actual LED current remains stable.

System Integration Effects

Harness routing, connector integrity, and chassis grounding implementation affect reference stability and can create intermittent flicker that varies with mechanical assembly conditions.

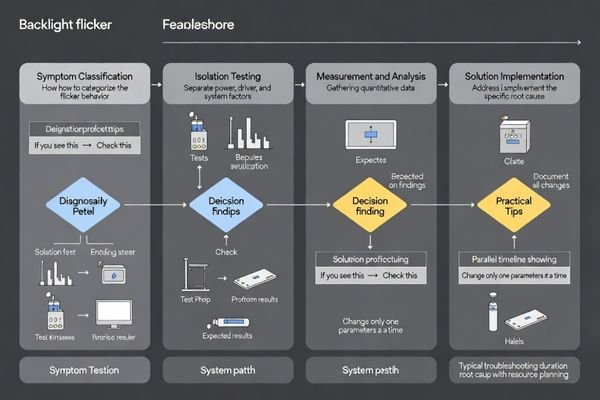

How do you build a fast, safe troubleshooting workflow for flickering backlights?

Systematic troubleshooting workflow organization enables rapid backlight flicker diagnosis while avoiding unnecessary component changes and system modifications.

Effective workflow begins with symptom classification to separate brightness-dependent, temperature-dependent, or load-triggered flicker, followed by controlled testing with known-good power sources, dimming configuration validation, and layout risk assessment under representative system conditions.

Workflow discipline prevents iteration cycles that result from changing multiple parameters simultaneously. The goal is to prove one hypothesis per test, record what changed, and keep conditions repeatable so the final fix remains stable in production.

Rapid Troubleshooting Workflow:

- Symptom Classification: Determine whether flicker correlates with brightness setting, temperature rise, camera-only conditions, or system load events to narrow the mechanism early

- Power Supply Validation: Lock brightness at a fixed level and test with a known-good external supply to isolate system power path issues from driver and load problems

- Configuration Optimization6: Verify dimming parameters (PWM frequency and limits), current limits, and any mode selection (PWM vs analog if available) match the LED string and operating requirements

- Quick Waveform Checks: Measure input rail droop during load/brightness events, LED string voltage behavior, and LED current ripple to distinguish dropout/protection cycling from loop instability

- Grounding/Layout Review: Inspect sense reference cleanliness, capacitor placement, switching loop area, and return paths; confirm connector integrity and harness routing assumptions

- Representative Re-Test: Repeat the same tests with the intended harness length, routing, and enclosure grounding to confirm the fix holds outside a bench setup

- Stop Criteria: If flicker persists at 100% brightness under stable input power and does not track PWM settings, prioritize headroom, grounding/layout, and protection-cycling causes over further parameter tweaking

FAQ

Why does backlight flicker appear only at low brightness?

Low brightness often uses small PWM duty cycles or low analog current levels where control loops and perception effects are more sensitive, making artifacts and instability more visible.

Can an unstable system power rail cause flicker even if the LED driver is rated correctly?

Yes. Input droop, transients, or noise can push the driver into dropout or protection behavior, producing visible flicker even when average ratings look acceptable.

What is the quickest test to separate mapping/timing issues from backlight flicker?

Freeze the displayed image and observe whether brightness fluctuates uniformly across the screen. Backlight flicker changes luminance, while mapping/timing issues typically affect image content, tearing, or synchronization.

How do I choose PWM frequency to reduce visible flicker?

Choose a frequency high enough to avoid visible modulation under expected viewing conditions and camera requirements, while staying within driver and EMI constraints; verify with your actual enclosure and dimming range.

Can poor grounding alone create flicker?

It can. Noise on the current-sense reference or ground bounce can modulate the regulation loop and create apparent current ripple that becomes visible as flicker.

When should I consider redesign versus parameter tuning?

If flicker persists at full brightness, under stable power, and across dimming modes, the root cause is likely in layout, grounding, or insufficient headroom—issues that often require hardware changes for robust production stability.

Conclusion

Backlight flicker troubleshooting requires systematic analysis of power supply stability, driver configuration, and layout factors that affect LED current regulation. Success depends on distinguishing between PWM artifacts and actual electrical instability through controlled testing and measurement correlation with operating conditions. Understanding the interaction between power path design, grounding implementation, and system integration enables faster convergence on stable solutions while avoiding unnecessary component substitution.

MEIDAYINGNUO provides comprehensive backlight system design and troubleshooting support including power supply analysis, driver configuration optimization, and layout review for stable operation across operating conditions. Our engineering team specializes in systematic diagnostic techniques that separate component issues from integration problems while providing proven solutions for production-ready backlight stability. Contact our technical team when backlight flicker challenges require expert analysis and validated troubleshooting workflows for reliable long-term operation.

✉️ info@lcdmodulepro.com

🌐 https://lcdmodulepro.com/

-

Understanding the causes of backlight flicker can help you troubleshoot and prevent issues in LCD display modules. ↩

-

Understanding PWM modulation is crucial for diagnosing flicker issues in LED drivers, ensuring optimal performance. ↩

-

Exploring the causes of electrical flicker can enhance your knowledge of LED performance and stability, leading to better lighting solutions. ↩

-

Exploring backlight stability will provide insights into its critical role in ensuring optimal display performance. ↩

-

Understanding best practices for LED drivers can help you maintain stability and performance in your designs. ↩

-

Exploring configuration optimization techniques can enhance LED performance and reduce flicker, ensuring a better user experience. ↩