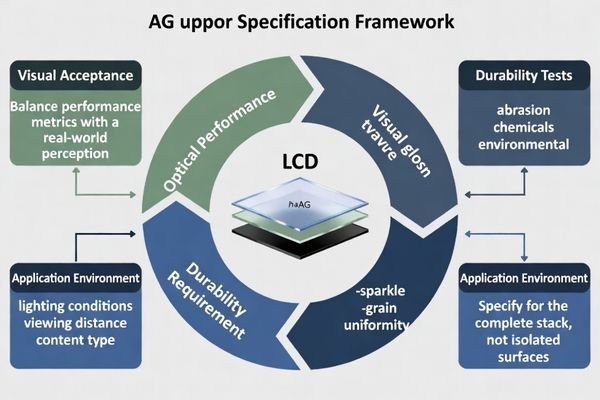

AG surface treatment specification should define optical targets, test conditions, visual acceptance, and durability validation as one closed loop, tied to the real application environment and the final display stack.

An acceptable AG surface is not a single haze value. It is a practical balance between glare reduction, readable contrast, uniform appearance, and durability under real use. Acceptance should cover what users see, what cameras capture, and what production can repeat across lots with controlled defects and stable yield. Define it for the actual stack and lighting.

Teams often over-focus on one metric and miss stack interactions, measurement geometry, and wipe or chemical exposure. A strong specification prevents supplier interpretation gaps, aligns engineering and quality early, and reduces field complaints caused by glare, sparkle, or post-stress appearance drift. The goal is repeatable performance across real lighting, consistent mass production, and long-term reliability1 without disputes.

What does "acceptable" mean for AG surface treatment in LCD modules?

Acceptable AG treatment represents balanced performance meeting optical requirements, visual quality expectations, and durability standards under specific application conditions rather than absolute specifications.

“Acceptable” should be defined as a repeatable outcome in your real environment, not a generic label. It means glare is reduced without obvious milky haze, sparkle is controlled at the intended viewing distance, and contrast remains stable for the content. It also means the same look can be produced across lots with clear defect limits.

In practice, acceptance must be scenario-specific because display luminance, pixel density, cover lens structure, and viewing geometry change the perceived result. Define the typical ambient lighting, viewing distance, and tilt angle, then evaluate the finished stack, not an isolated surface coupon, since bezel and edge reflections can alter real perceived glare.

User Perception Requirements

Acceptable AG treatment must reduce harsh reflections and sparkle visibility while maintaining adequate contrast and color fidelity under typical viewing conditions, requiring evaluation at actual viewing distances and lighting environments representative of deployment scenarios.

Manufacturing Consistency Standards

Production acceptance requires consistent optical properties2 across manufacturing lots, controlled defect levels, and stable yield rates ensuring reliable supply and quality consistency throughout product lifecycle and volume production requirements.

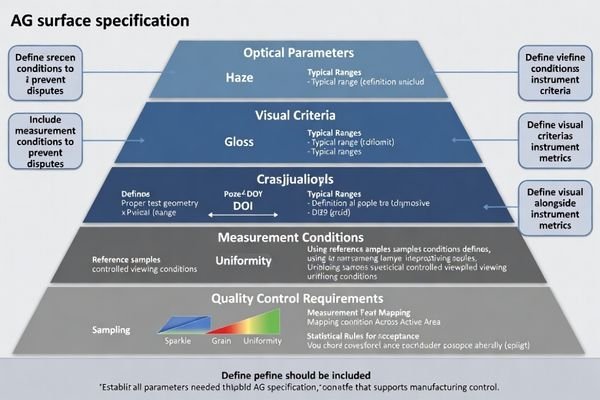

Which parameters should be written into the AG surface specification?

Comprehensive AG specification requires systematic definition of optical targets, measurement conditions, visual criteria, and durability requirements ensuring reproducible results and manufacturing control.

A complete AG specification must define the stack location and method, target optical ranges (haze, gloss, and optional DOI), and visual criteria for sparkle, grain, color shift, and uniformity. It must also lock measurement conditions, sampling/AQL, and change-control rules. Numbers without method and conditions frequently cause disputes in mass production.

To make the document executable, include test geometry and instrument details, sample conditioning, measurement mapping across the active area, and the statistical rule used for pass/fail. Pair instrument limits with a controlled visual grading setup using reference samples (golden sample + boundary samples). Clarify defect definitions3 (scratch, pit, contamination, non-uniform haze) and whether acceptance is based on average, max, or a defined percentile.

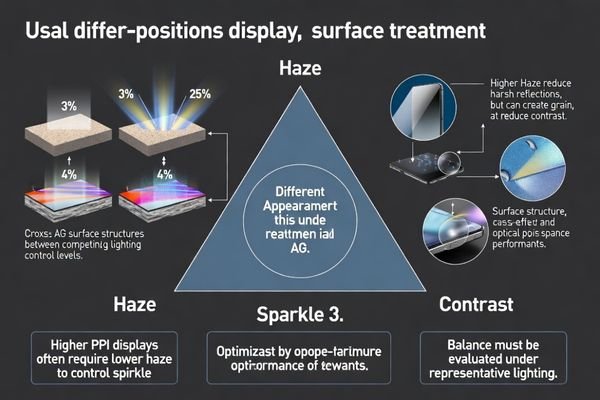

How do you balance haze, sparkle, and contrast for real viewing environments?

Optimal AG balance requires systematic evaluation under representative lighting conditions accounting for display characteristics, viewing geometry, and content requirements for specific applications.

Higher haze can reduce mirror reflection but may lower perceived contrast and add a milky look. Lower haze preserves contrast but can leave harsh glare and increase sparkle, especially on high-PPI displays at short distance. Balance must be evaluated in representative environments with the final stack and a repeatable visual method, not haze alone.

For engineering alignment, define four representative environments: office overhead lighting, near-window daylight, dim indoor, and outdoor semi-shaded. Validate with a controlled setup that matches the real stack, bezel, and viewing geometry because small changes in cover thickness, air gap, or bonding can shift perceived glare and grain. Combine instrument metrics with standardized visual grading since sparkle and grain are often best captured by controlled viewing with defined distance, angle, and content patterns.

| Environment Type | Key Characteristics | AG Balance Strategy | Critical Evaluation Parameters |

|---|---|---|---|

| Office Overhead Lighting | Uniform illumination, moderate intensity | Moderate haze for glare control4 | Sparkle visibility, contrast retention |

| Near-Window Daylight | High intensity, directional lighting | Higher haze for reflection control | Milky appearance limits, readability |

| Dim Indoor Conditions | Low ambient light, minimal reflections | Lower haze for contrast preservation | Color accuracy, viewing angle performance |

| Outdoor Semi-Shaded | Variable intensity, multiple light sources | Balanced haze with high contrast | Reflection control, readability range |

Environmental balance optimization ensures AG treatment provides effective glare control while maintaining visual quality and readability across the full range of expected operating conditions and user interaction scenarios.

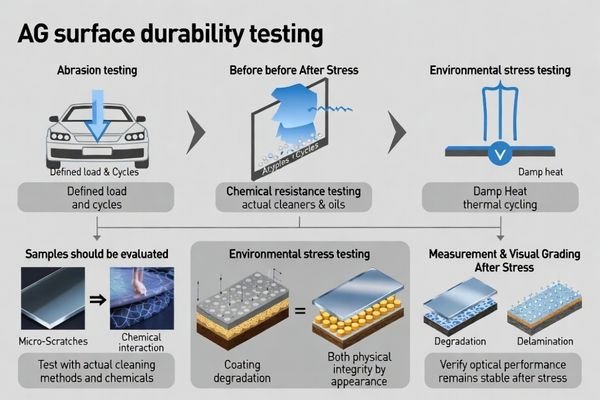

How should reliability and durability tests be defined for AG-treated module surfaces?

Durability testing requires systematic evaluation of AG surface integrity under mechanical stress, chemical exposure, and environmental conditions representative of actual deployment scenarios.

Durability testing must reflect wiping, handling, and the real environment. Define abrasion under specific load/cycles, scratch resistance expectations if hardcoat is used, and chemical resistance to actual cleaners and oils. Add damp heat and thermal cycling, then re-measure optical values and re-grade appearance after stress, because drift often fails acceptance before peeling does.

Appearance drift is a common failure mode: micro-scratches increase local haze, chemical exposure changes gloss, and thermal/humidity stress can shift coating microstructure. For stacks with cover lens or touch integration, include adhesion and delamination checks across the full assembly, and confirm that nearby conductive layers do not create ESD/EMI side effects that impact touch or display performance. Keep pass/fail tied to both physical integrity and post-stress optical/visual criteria so quality decisions remain aligned with user perception.

Mechanical Stress Testing Requirements

Abrasion Resistance Evaluation:

Test wiping/abrasion using defined load, material, and cycles that match real maintenance. After the test, re-check haze/gloss uniformity and visually grade sparkle and grain versus reference samples to confirm no meaningful appearance shift in the active area.

Adhesion and Delamination Assessment:

Evaluate adhesion through thermal cycling and humidity exposure on the full stack where applicable. Acceptance should include no delamination plus post-stress confirmation that optical targets and visual grades remain within limits.

Environmental and Chemical Durability Validation

Chemical Resistance Testing5:

Expose samples to the actual cleaners, oils, and contaminants expected in the field. Confirm there is no whitening, gloss change, or uneven haze, and re-grade appearance under the same visual booth conditions used for initial acceptance.

Environmental Stress Validation:

Apply damp heat, thermal cycling, and extended high-temperature storage aligned with deployment risk. Re-measure optical parameters and repeat visual grading to ensure AG performance and uniformity remain stable over time.

How to choose an AG-treated LCD module solution for your product?

AG solution selection requires systematic analysis of application requirements, stack architecture, and engineering trade-offs to achieve optimal balance between optical performance and integration constraints.

Selection should start from real lighting and viewing constraints, then work backward to AG target that protects readability without over-sacrificing contrast while considering complete stack integration requirements and lifecycle management needs.

Application Requirements Analysis

Environmental and Viewing Condition Assessment:

Define the use scenario, lighting intensity and directionality, typical viewing distance, and content type (text-heavy vs image-heavy). Use these inputs to set practical glare and sparkle limits while preserving contrast and color stability under the actual operating conditions.

Stack Architecture Considerations:

Decide where AG belongs in the stack and whether touch is present. Each added interface increases reflection risk and can amplify haze or sparkle if mismatched, so specify the full stack definition and confirm performance on representative builds, not on isolated layers.

Engineering Trade-off Optimization

Performance Balance Evaluation:

Align display size/resolution with expected viewing distance to avoid visible grain, confirm viewing-angle behavior across the intended range, and ensure the interface/timing and signal chain do not introduce artifacts. Also validate backlight control behavior6 so dimming does not create perceived shimmer or non-uniform appearance.

Integration and Lifecycle Management:

Plan mechanical mounting and sealing to prevent edge reflections and light leaks, and choose bonding strategies that reduce internal reflections. Include reliability validation, serviceability expectations, and supply continuity/change-control measures so appearance and performance remain stable across production years.

Selection Methodology Implementation

Systematic Evaluation Process:

Build acceptance criteria that combine instrument metrics with repeatable visual grading, approve a golden sample set, and validate on prototypes built with the real assembly process. Define change-control steps to qualify any material, process, or supplier shifts before mass production release.

Validation and Quality Control:

Use controlled testing under representative lighting, define sampling and AQL rules for production monitoring, and implement periodic audits that include optical re-measurement and visual grading. This maintains consistency across lots and reduces the risk of late-stage disputes.

FAQ

Q: Does higher haze always mean better anti-glare performance?

A: Not necessarily. Higher haze can reduce mirror-like reflections, but it can also lower perceived contrast and introduce a milky look or stronger grain. “Better” must be judged in the target lighting and viewing distance with the final stack.

Q: Why do two suppliers show the same haze value but different visual results?

A: Measurement setups can differ (instrument geometry, aperture, calibration, sample conditioning, and averaging rules). Sparkle and grain also depend on panel PPI, backlight, and stack reflections, so haze alone is not enough without defined conditions.

Q: Should AG be on the cover lens or on an internal surface of the module stack?

A: It depends on scratch exposure, cleaning habits, and whether touch is present. External AG can control reflections effectively but needs stronger abrasion/chemical resistance. Internal AG may be better protected but can leave external reflections untreated unless combined with other measures.

Q: How should sparkle and grain be evaluated in a repeatable way?

A: Define a controlled lighting booth, viewing distance, angle, and reference samples, then use a standardized visual grading method alongside instrument metrics. Sparkle perception is highly sensitive to geometry, content, and stack interfaces.

Q: What durability tests matter most for AG surfaces in industrial use?

A: Abrasion/wipe testing with defined load and cycles, chemical resistance to the real cleaners and oils, and thermal/humidity cycling that can shift appearance over time. Acceptance should include post-test optical re-measurement and visual grading, not only adhesion.

Q: How can we reduce the risk of mass-production disputes about AG appearance?

A: Lock the stack definition, measurement conditions, and visual acceptance criteria early, approve golden samples, and define sampling/AQL and change-control rules so process drift or material substitutions are detected and qualified before shipment.

Conclusion

AG surface treatment specification requires comprehensive approach that extends beyond simple haze values to include systematic parameter definition, measurement conditions, visual acceptance criteria, and durability requirements tailored to specific application environments. Effective specification balances glare reduction with contrast preservation while ensuring manufacturing consistency and long-term reliability under actual use conditions. By defining complete stack architecture, establishing controlled testing methodology, and implementing systematic validation procedures, teams can achieve optimal AG performance that maintains readability in bright environments while preventing production disputes and appearance variations throughout manufacturing lifecycles.

MEIDAYINGNUO provides comprehensive AG surface treatment specification and optimization services for LCD module applications requiring systematic parameter definition, durability validation, and performance optimization across demanding environmental and operational requirements. Our engineering team offers specialized expertise in AG surface analysis, environmental testing methodology, specification development, and quality control implementation ensuring LCD modules deliver consistent anti-glare performance while maintaining optical quality and manufacturing feasibility throughout extended deployment periods. Contact our AG optimization specialists when surface treatment challenges require expert specification development and systematic validation support for successful display integration projects.

✉️ info@lcdmodulepro.com

🌐 https://lcdmodulepro.com/

-

Exploring long-term reliability strategies can enhance product durability and customer satisfaction, making it a vital resource. ↩

-

Understanding optical properties is crucial for ensuring product quality and performance in various applications. ↩

-

Understanding defect definitions is crucial for effective quality control and ensuring product standards. ↩

-

Explore this link to understand various glare control strategies tailored for specific lighting environments, enhancing visual comfort. ↩

-

Exploring chemical resistance testing methods can help ensure your materials withstand real-world conditions effectively. ↩

-

Exploring backlight control behavior can help you learn how to prevent issues like shimmer and ensure consistent display quality. ↩