How do you choose modules for logistics sorting equipment?

Logistics sorting equipment runs long hours with fast operator workflows and tough conditions like dust, vibration, temperature swings, and EMI

Logistics sorting equipment runs long hours with fast operator workflows and tough conditions like dust, vibration, temperature swings, and EMI

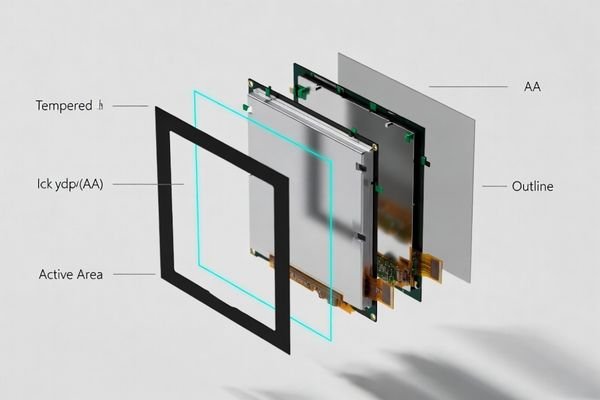

Active area is the LCD’s true pixel boundary, not the outer glass or frame. Because modules include non-display regions (mask,

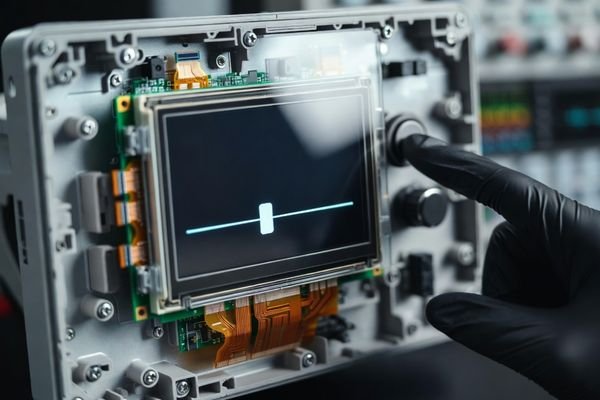

A true line defect typically stays in the same pixel position across test patterns and normal viewing angles. If the

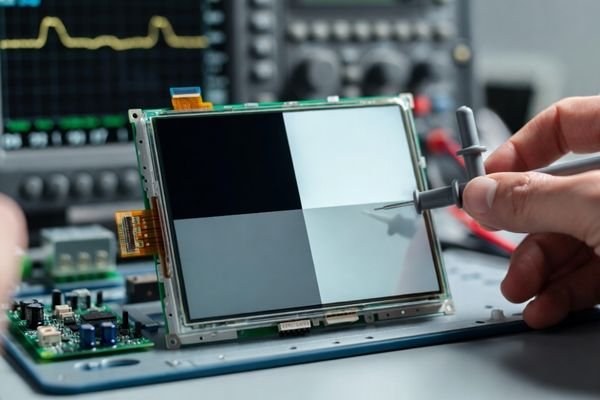

Brightness is only enforceable in procurement when test conditions are locked. Define what is measured (luminance at the display surface),

Input lag is the end-to-end delay from an input (touch, click, key press) to visible feedback on the display. It

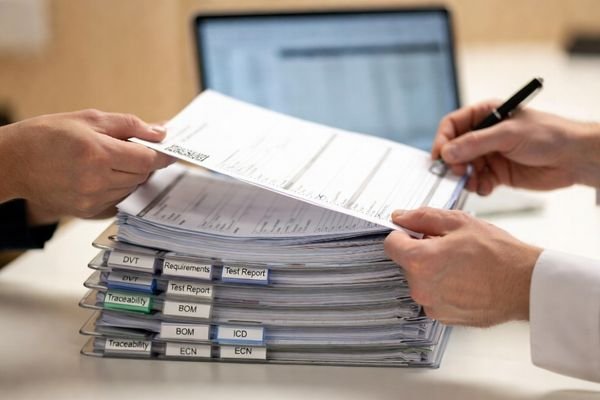

PVT deliverables prove production readiness: a locked build configuration, repeatable production-intent processes, and standardized quality evidence with stable yield. For

DVT deliverables are an evidence package: they freeze the validated design configuration and prove requirement coverage with traceable test plans,

A sudden contrast drop is usually caused by a shifted operating point: LCD bias/VOP or VCOM drifting, backlight or ambient

EVT deliverables should let another engineer rebuild the module, rerun the same tests, and reach the same conclusions. Provide a

We will contact you within 1 working day, please pay attention to the email with the suffix “@lcdmodulepro.com”.