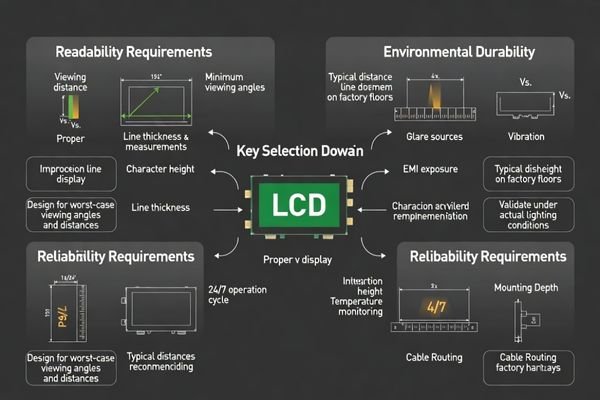

Production line dashboard module selection requires balancing readability requirements, environmental durability, and long-term reliability for continuous industrial operation.

Production line dashboard module selection requires evaluating viewing distance and angle requirements, ambient lighting and glare conditions, interface stability under EMI exposure, and long-term reliability for 24/7 operation. Effective selection balances size and resolution for operator readability, brightness and optical treatments for factory floor visibility, robust interfaces for industrial environments, and lifecycle consistency supporting multi-year deployment across production facilities.

Production line dashboards are “glance displays”: operators must read key KPIs quickly, at real distances, under mixed lighting, and often from off-axis positions while moving. That makes module selection a system decision focused on readable information design, glare control1, stable behavior under industrial electrical noise, and predictable long-term support. A useful outcome of this process is a deployable spec package: target viewing distance/angles, minimum character height for critical KPIs, brightness and cover-lens strategy, interface/cable plan, thermal and backlight lifetime assumptions, and acceptance tests that keep units consistent across lines and batches.

What makes production line dashboards different from typical LCD module use cases?

Production line dashboards require optimization for dependable readability, continuous operation, and industrial environmental conditions rather than visual appeal.

Production line dashboards prioritize dependable readability, uptime, and consistency across shifts and environments over visual aesthetics, operating with static or semi-static content for extended periods while maintaining legibility under mixed lighting including overhead LEDs, daylight spill, and reflections from various viewing angles. Integration constraints include enclosure depth limitations, cable routing near motors and power equipment, EMI and ESD exposure, and stable behavior during frequent power cycling or network reconnections.

In factory deployments, the “best-looking” panel on a bench can fail in the field because dashboards live with glare, vibration, electrical noise, and long run times. Selection priorities shift toward readability under reflections, stable operation during power events, and consistent performance across many identical installations. Because dashboards are often replicated across multiple lines, batch-to-batch consistency and lifecycle continuity can outweigh peak specifications. Treating these requirements as first-class inputs prevents late-stage fixes like oversized enclosures, excessive brightness, or repeated field adjustments.

Operational Environment Demands

Production floors combine overhead fixtures, daylight spill, and reflective machinery, so glare and off-axis viewing are routine rather than edge cases. Operators rarely stand perfectly centered; they approach from aisles, glance while walking, and rely on quick recognition of alarm colors and large numbers. Electrical noise from motors and power equipment can stress signal integrity2 and control lines, so “stable in the lab” is not a sufficient criterion. Validate the module choice against the real floor layout and lighting, not only a spec sheet.

Integration Constraint Management

Dashboard installations are constrained by mounting depth, cable routing, and service access, and they often experience frequent power cycling or network reconnect events. Plan for clean strain relief, reliable connectors, and predictable initialization and recovery behavior so the display returns to a readable state without manual intervention. Consider maintenance workflows: how quickly a unit can be replaced, whether replacement parts will match optics and color, and what quick checks confirm acceptable performance. These integration realities heavily influence which modules are “easy to deploy at scale.”

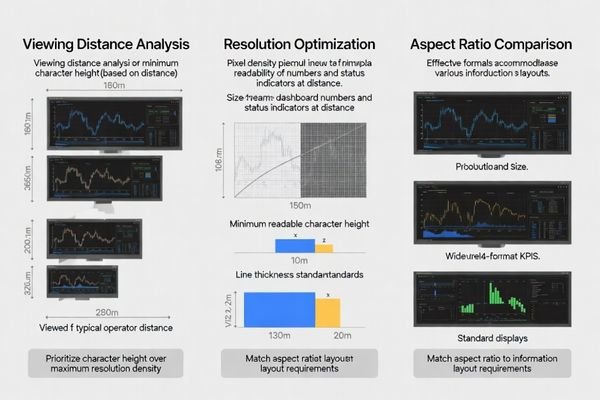

What size, resolution, and aspect ratio best support dashboard readability at distance?

Size and resolution optimization should prioritize operator readability and information layout efficiency over specification maximization.

Dashboard size and resolution selection should prioritize legibility of key numbers, status colors, and alarms at real viewing distances, often favoring larger pixels and clear typography over maximum resolution density. Size and aspect ratio choices should match information layout requirements with wide formats supporting multi-column KPIs and timeline displays while standard rectangles accommodate legacy UI frameworks and camera preview integration.

A practical rule is to design from the floor backward: pick the typical viewing distance and off-axis angles, then ensure critical KPIs meet a minimum character height and line thickness at that distance. Resolution should be treated as layout density, not a quality badge—overly dense layouts reduce glanceability3 and increase operator mistakes. Wide aspect ratios can improve scanning for multi-column KPIs, shift summaries, and line-wide status bars, while standard rectangles may simplify software reuse and reduce integration complexity. Prototype the UI at scale early so the module choice is driven by real readability rather than assumptions.

How do brightness, contrast, and anti-reflection choices impact factory-floor visibility?

Optical performance optimization must address factory lighting conditions and reflection management for consistent visibility.

Factory floor visibility depends on managing reflections and glare as much as raw luminance, requiring brightness strategies matching ambient lighting ranges and optical treatments including anti-glare or anti-reflection cover lenses, appropriate haze levels, and polarization considerations. Contrast and color performance support status signaling effectiveness, particularly for quick recognition of red, amber, and green operational states from various viewing angles under challenging lighting conditions.

On production floors, glare control4 often improves readability more than simply increasing brightness. Start by identifying glare sources (overhead fixtures, skylights/windows, shiny equipment) and the dominant reflection angles relative to operator positions. Then choose optical treatments—cover lens, surface finish, anti-glare/anti-reflection approach—so reflections are reduced without making text look hazy or colors muddy. Validate contrast and color recognition at working angles, because alarms and status cues must remain unambiguous even when the operator is not centered. Always verify under real shift lighting, since lab lighting can underestimate washout.

| Visibility Factor | Industrial Challenge | Optimization Strategy |

|---|---|---|

| Ambient Lighting | Mixed LED and natural light | Brightness range matching with dimming capability |

| Reflection Control | Overhead fixtures and glossy surfaces | Anti-glare treatments and surface texture optimization |

| Viewing Angles | Operator movement and positioning | Wide viewing angle validation at working distances |

| Color Recognition | Status indication clarity | Contrast optimization for critical color coding |

Validation should include real lighting scenarios across day and night shifts, nearby windows, and angled viewing positions because laboratory conditions often fail to predict actual factory floor visibility challenges.

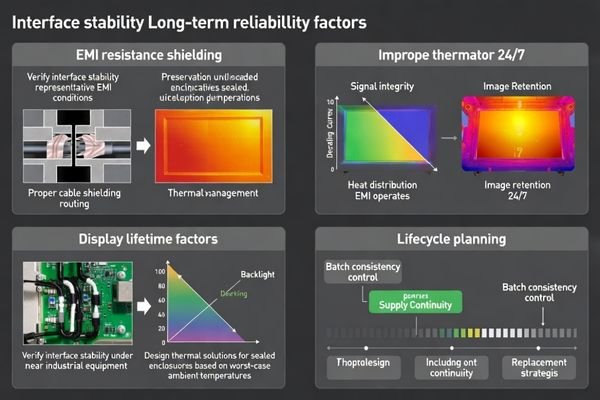

What interfaces, reliability factors, and lifecycle risks matter most for 24/7 dashboards?

Interface stability and long-term reliability require evaluation of EMI resistance, thermal management, and component lifecycle consistency.

Production dashboards benefit from interfaces providing stability under EMI exposure, long cable runs, and frequent power cycling with predictable initialization and recovery behavior. Reliability considerations include backlight lifetime and thermal derating, heat management in sealed enclosures, image retention prevention for static content, and protection against ESD and electrical transients common near industrial equipment, while lifecycle planning addresses supply continuity, optical performance consistency across production batches, and clear end-of-life strategies.

For 24/7 dashboards, failures are expensive because they disrupt visibility and maintenance time across multiple lines. Prioritize stable interface behavior in noisy environments, predictable boot/recovery behavior after power events, and thermal headroom5 that supports long backlight life without aggressive drive conditions. Static content introduces image retention risk, so consider both module behavior and UI patterns that reduce persistent high-contrast elements. Just as important is lifecycle continuity: dashboards are deployed for years, so consistent optics across batches and a clear EOL plan reduce redesign risk and keep replacements visually matched. For comprehensive reliability analysis and industrial interface optimization support during complex dashboard deployment planning, engineering teams can contact info@lcdmodulepro.com when systematic validation requires specialized industrial environment expertise.

Interface Robustness Requirements

Industrial environments demand interface solutions resistant to EMI and capable of stable operation over the planned cable routing and connector strategy. Ensure grounding, shielding, and cable placement are considered during selection, not after issues appear, because “long cable + noisy equipment” can create intermittent link problems. Verify predictable initialization and recovery so the display returns to a known-good state after power cycling. Where possible, validate in a representative EMI environment or during on-line trials.

Long-Term Reliability Planning

Backlight lifetime and optical consistency are central for dashboards that run continuously. Validate thermal behavior in the actual enclosure, including hot spots and airflow assumptions, because high temperature accelerates aging and increases drift risk. Define acceptance criteria for brightness uniformity, color consistency, and pixel defects using golden samples, so replacements remain visually consistent. Include a lifecycle plan covering supply continuity and an EOL strategy to avoid disruptive mid-life redesigns.

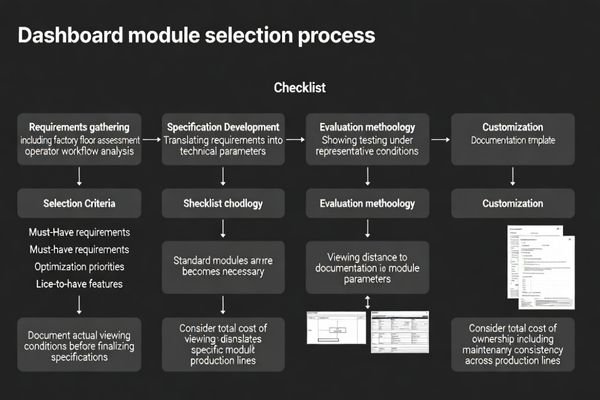

How do you build a selection checklist for dashboard modules and decide when to customize?

Systematic selection requires translating operational requirements into module specifications with clear customization decision criteria.

Effective selection checklists start from dashboard operational context including viewing distance and angles, ambient lighting and glare sources, required readability of key performance indicators, and expected duty cycles. Translation into module decisions covers size and aspect ratio for layout optimization, brightness and optical stack choices for visibility assurance, interface and timing stability for EMI resilience, power and thermal design for extended backlight operation, plus mechanical integration addressing mounting, cover lens selection, cable management, and serviceability requirements.

A checklist works best when it turns “readable on the floor” into measurable requirements and repeatable acceptance tests. Define viewing distance/angles and minimum KPI legibility, then lock the optical plan (brightness target plus cover lens treatment) to control glare across shifts. Confirm the interface and timing approach stays stable in EMI-heavy routing, and ensure the thermal/backlight plan6 supports 24/7 life without running at fragile margins. Add integration and serviceability items—mounting, strain relief, replacement workflow—and quality controls such as golden samples and controlled test conditions for batch comparability. Customization is the better path when constraints stack up (extreme glare, unusual aspect ratios for line-wide layouts, sealed enclosures with limited thermal headroom, or strict multi-line consistency requirements) because co-optimizing optics, backlight design, mechanical stack-up, and validation as one system typically reduces total deployment risk.

FAQ

Should a production line dashboard prioritize brightness or anti-reflection first?

In many factories, reflection control drives perceived readability; target brightness must be set alongside cover lens and surface treatment choices to avoid washout from glare.

How do I avoid image retention on dashboards that show static content?

Use UI design techniques (subtle motion, periodic shifts), avoid constant high-contrast static elements, and validate the module’s behavior under long-duration static patterns at operating temperature.

What viewing angle should I design for on a busy production floor?

Design for the most common off-axis positions where operators stand or walk, and verify that contrast and color status cues remain clear at those angles.

Do long cables make dashboard displays less reliable?

They can, especially in EMI-heavy environments; stable interface choice, grounding, shielding, and careful cable routing help prevent intermittent link issues.

What acceptance tests matter most when deploying many dashboards across lines?

Focus on readability-critical metrics like brightness uniformity, color consistency, pixel defect criteria, and thermal stability, using golden samples and controlled conditions for comparability.

When is customization the right choice for a dashboard module?

When glare, aspect ratio, enclosure constraints, or consistency requirements cannot be met with a standard module without unacceptable trade-offs, customization reduces overall integration risk.

Conclusion

Choosing modules for production line dashboards requires systematic evaluation of real-world readability requirements, environmental challenges, and long-term reliability needs rather than focusing primarily on specification maximization. Success depends on matching size and resolution to information scanning patterns, controlling glare through appropriate optical treatments, and ensuring electrical, thermal, and reliability margins supporting continuous operation. Effective selection processes treat module choice as system-level optimization where validation under factory lighting and EMI conditions guides decision-making rather than laboratory testing alone.

MEIDAYINGNUO provides specialized dashboard module selection and customization services for production line applications requiring optimized readability, environmental durability, and long-term reliability across demanding industrial deployment scenarios. Our engineering team offers comprehensive support including operational requirement analysis, optical performance validation under factory lighting conditions, interface stability testing for EMI-heavy environments, and custom integration solutions ensuring dashboard modules maintain consistent performance throughout extended production facility lifecycles. Contact our technical specialists when dashboard deployment requires expert industrial environment analysis and systematic module optimization for reliable long-term operation.

✉️ info@lcdmodulepro.com

🌐 https://lcdmodulepro.com/

-

Effective glare control enhances visibility and readability, crucial for operators in dynamic industrial environments. ↩

-

Understanding signal integrity is crucial for ensuring reliable performance in production environments, making this resource invaluable. ↩

-

Exploring glanceability can enhance user experience by making information easier to digest quickly, reducing errors and improving efficiency. ↩

-

Exploring this resource will provide insights into effective glare control techniques that enhance visibility and safety on production floors. ↩

-

Understanding thermal headroom is vital for extending backlight life; this link provides insights into managing heat effectively. ↩

-

A solid thermal/backlight plan is essential for maintaining display longevity and performance, especially in demanding environments. ↩