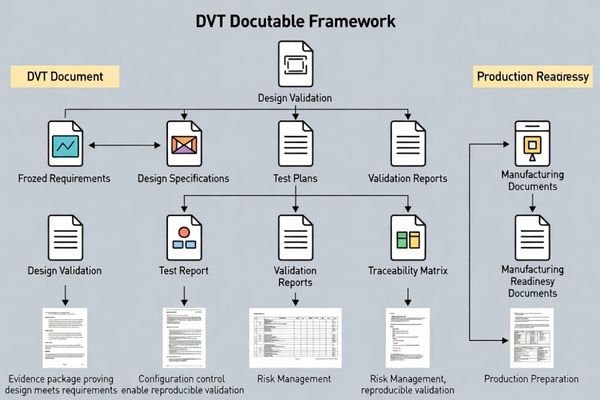

DVT deliverables are the evidence set that proves the design meets requirements in representative conditions and can be reproduced consistently. A good package prevents “validating a moving target” by locking the configuration, linking requirements to verification evidence, and documenting what changed, what passed, what failed, and what risks remain before PVT.

DVT deliverables are an evidence package: they freeze the validated design configuration and prove requirement coverage with traceable test plans, results, and change records. For LCD display module integration, they capture optical, electrical, and mechanical assumptions, making failures diagnosable, changes auditable, and the PVT handoff predictable.

In many LCD display module programs, schedule slips and quality surprises come from documentation gaps rather than “unknown physics.” If the DVT build configuration (BOM, firmware, calibration) is unclear, test results become hard to compare, and teams unintentionally validate different design states across builds.

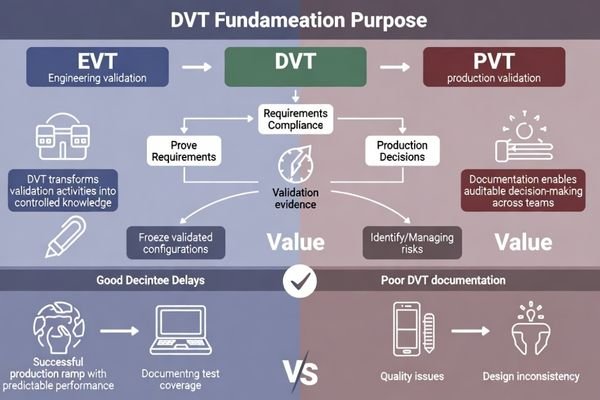

A strong DVT package converts validation activities into controlled knowledge: it shows what was verified, with what setup and criteria, against which revision, and with what closure plan for failures. That clarity reduces rework during PVT ramps1 and keeps design intent intact through the next phase.

What is the real purpose of DVT deliverables?

DVT deliverables serve as evidence packages proving design validation against requirements while enabling reproducible performance and predictable production handoff.

DVT deliverables exist to prove the design meets requirements and to lock the exact validated configuration. They document what was tested, how it was measured, what passed or failed, what changed, and what risks remain. For LCD display module integration, this evidence links requirements to controlled outputs (specs/drawings/config) and to verification results that support PVT decisions.

The practical purpose is decision support: can the program move forward with known risks and repeatable performance? This requires traceability and configuration control so DVT does not validate a moving target. DVT documentation should allow any reviewer—engineering, quality, operations—to audit what “validated” means for this design revision and build configuration.

Design Validation Evidence2

DVT deliverables are the proof that requirements were verified with defined methods and pass/fail criteria. Each item should point to measurable acceptance criteria, the exact test setup/fixture, sample size, and the raw data location. If a requirement is not verified, it should be explicitly marked as a gap with an owner and plan.

Production Readiness Foundation

While DVT is design-focused, it sets the baseline for later phases by freezing the validated configuration and capturing the learnings that prevent rework. A clear DVT evidence set helps operations avoid re-discovering known issues during PVT and reduces ambiguity when multiple teams build or test the same module.

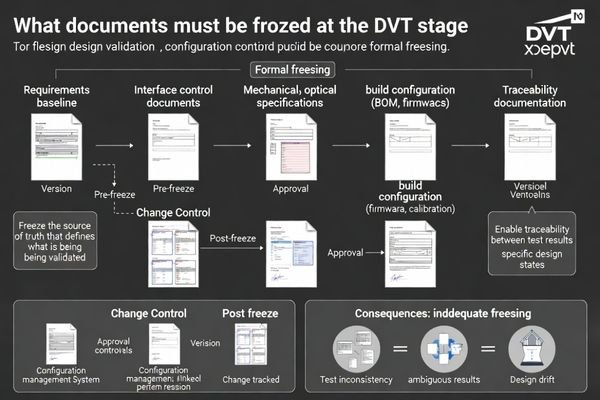

Which requirement and design-control documents must be frozen at DVT?

DVT requires freezing requirement baselines and design-control documentation defining validated configurations with complete traceability and change management.

At DVT, freeze the requirements baseline and the design “source of truth” that defines what is being validated. This includes the spec/requirements document with revision history, an interface control document (ICD) covering electrical interfaces and timing assumptions, and controlled mechanical/optical integration drawings. Also lock traceability (requirements-to-test mapping), change records (ECN/ECR), and the exact DVT configuration (BOM, firmware, calibration) so results map to a specific design state.

A repeatable DVT outcome depends on unambiguous configuration management3. If the BOM revision or firmware build is unclear, two “DVT units” may behave differently for reasons unrelated to the design itself. Freezing the baseline ensures that test results, failures, and corrective actions can be compared across builds and reviewed with confidence.

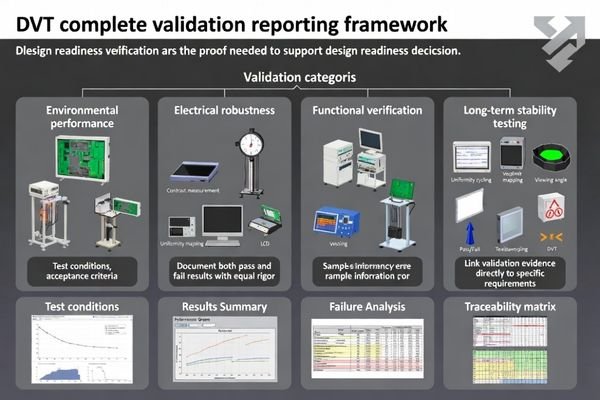

What validation reports prove the design is ready to move forward?

DVT validation reports must provide comprehensive evidence covering environmental, electrical, functional, and stability performance against defined acceptance criteria.

DVT readiness is proven by test plans and reports that match real acceptance criteria: environmental coverage (temperature range/cycling and its impact on readability/contrast), electrical robustness (rail margins, EMI/ESD, brownout behavior), functional performance (brightness targets, viewing-angle expectations, uniformity), and stability/aging where applicable. Each report must include setup/fixtures, sample size, pass/fail criteria, raw data links, failure analysis, corrective actions, and retest results.

The goal is not “no failures,” but controlled learning. A useful DVT report4 makes failures actionable: it captures reproduction conditions, suspected root cause, the fix, and the evidence that the fix works. If an issue is carried forward, it should be listed as an explicit risk with mitigation, ownership, and planned closure timing.

| Validation Category | Key Test Areas | Required Evidence |

|---|---|---|

| Environmental Performance | Temperature cycling, humidity exposure | Contrast stability, response time validation |

| Electrical Robustness | Power margins, EMI/ESD testing | Rail tolerance, brownout recovery verification |

| Functional Verification | Brightness, uniformity, viewing angles | Performance against specification targets |

| Long-term Stability | Aging, endurance testing | Degradation rates and lifetime projections |

Systematic validation reporting supports a clear decision: what is proven, what is unproven, and what is accepted as a managed risk before entering PVT.

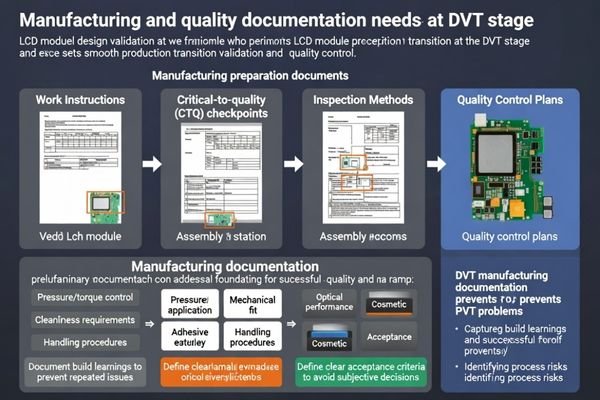

What manufacturing and quality documents reduce surprises in PVT?

DVT should include preliminary manufacturing documentation preventing build ambiguity and establishing quality control foundations for production phases.

Even in DVT, deliver a minimum manufacturing and quality package to prevent build ambiguity in PVT. Include draft work instructions, critical-to-quality (CTQ) checkpoints, inspection methods for key optical/mechanical items, and a draft control plan for what will be measured in PVT. For LCD modules, define assembly constraints affecting optics (pressure/torque limits, adhesive control points, cleanliness), incoming inspection criteria, and acceptable cosmetic/visual conditions.

To reduce repeat issues, add what the build actually taught you: top defects observed during DVT builds, yield-risk notes, and recommended fixture/process changes. This prevents manufacturing teams from re-learning known failure modes and shortens the time to a stable PVT process.

Quality Control Preparation

Define what will be inspected, how it will be measured, and what constitutes pass/fail for critical characteristics. For LCD display module integration, this often includes optical acceptance conditions5 (viewing angle, ambient lighting assumptions), mechanical fit checks, and clear criteria for cosmetic acceptance to avoid subjective rejections later.

Process Definition Foundation

Draft process definitions prevent ambiguity: how the module is handled, mounted, sealed, and cleaned; which steps are sensitive to torque/pressure; and which materials/adhesives require special controls. Even a preliminary version can prevent major variation when multiple builds occur across teams or sites.

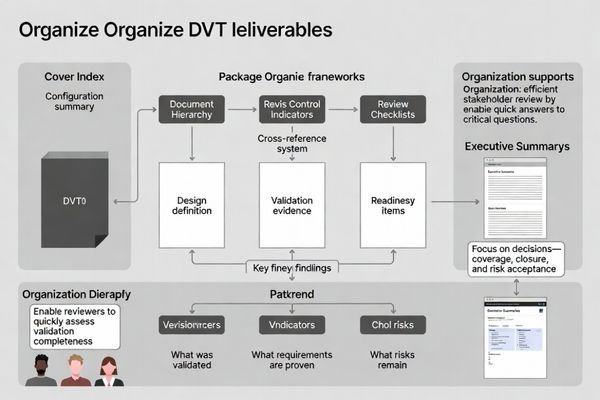

How do you package DVT deliverables into a review-ready checklist?

DVT packages require systematic organization enabling stakeholders to quickly assess design validation completeness and production readiness status.

A review-ready DVT package should let reviewers answer three questions fast: what design version was validated, what requirements were proven, and what risks remain. Start with a cover index listing the frozen DVT configuration (BOM/firmware/calibration), the requirements baseline, and the traceability matrix. Then group documents into design definition (specs/drawings/ICD), validation evidence (plans/reports/FA/retest), and readiness items (draft manufacturing pack, inspection methods, open-issue log).

Use consistent revision rules in a single controlled repository, link to raw data locations, and add an executive summary6 that highlights deltas from EVT, top failures, closed items, and carryover risks with owners and due dates. This keeps the DVT review focused on decisions—coverage, closure, and risk acceptance—rather than document hunting.

Document Organization Framework

Configuration Management:

- DVT build configuration including BOM revision, firmware version, and calibration parameters

- Requirements baseline with revision history and change tracking

- Traceability matrix linking requirements to verification methods and evidence

- Controlled revision management with clear version control and change documentation

Validation Evidence Package:

- Complete test plans with defined acceptance criteria and measurement procedures

- Comprehensive test reports including pass/fail results and failure analysis

- Raw data repositories with clear linking and accessibility for audit purposes

- Issue tracking with root cause analysis, corrective actions, and closure verification

Production Readiness Assessment:

- Preliminary manufacturing documentation including work instructions and quality checkpoints

- Inspection criteria and measurement methods for critical characteristics

- Open issue log with risk assessment, ownership, and mitigation planning

- Executive summary highlighting key findings, risks, and readiness recommendations

Review Process Optimization

Stakeholder Accessibility:

- Clear indexing enabling rapid location of relevant documentation and evidence

- Executive summaries providing high-level status without requiring detailed document review

- Decision-focused organization highlighting areas requiring stakeholder input or approval

- Standardized formatting ensuring consistent information presentation across projects

Decision Support Framework:

- Risk carryover documentation with explicit ownership and mitigation strategies

- Comparison summaries showing changes and improvements from previous validation phases

- Production readiness assessment with clear go/no-go criteria and supporting evidence

- Action item tracking ensuring completion of required activities before PVT progression

FAQ

Should DVT deliverables be different for a customized LCD module versus a standard module?

Yes—custom projects typically require tighter control of drawings, optical stack assumptions, and validation coverage, but the core idea remains traceability from requirements to test evidence and controlled design outputs.

What is the minimum "must-have" set for a DVT review?

Requirements baseline, build configuration definition, traceability matrix, key test plans/reports with pass/fail criteria, and an open-issues log with owners and mitigation.

How should failures be documented in DVT reports?

Include conditions, reproduction steps, measurements, suspected root cause, corrective action, and retest outcomes, plus links to raw data so others can audit conclusions.

Do we need manufacturing documents if we’re "not ready for production"?

You don’t need final work instructions, but you do need enough draft process and inspection definitions to prevent ambiguity and to de-risk the PVT build.

What’s the best way to manage document revisions during DVT?

Use a single controlled repository, clear revision rules, and a "DVT release" tag that locks the validated configuration; document any changes as ECNs.

How does a traceability matrix help at DVT?

It proves coverage—every requirement is linked to a verification method and evidence, and gaps are visible before moving to PVT.

Conclusion

DVT deliverables turn validation work into an auditable evidence package: a frozen configuration, proven requirement coverage, and explicit risk carryover. Strong DVT documentation combines controlled requirement baselines and design definitions, complete test reports with clear criteria and closure evidence, and a practical draft manufacturing/quality pack that reduces ambiguity in PVT. When the package is organized around traceability and configuration control, DVT reviews stay decision-focused and manufacturing ramps become faster and more predictable.

MEIDAYINGNUO provides DVT documentation and validation support for LCD display module projects, including requirements and configuration management, test plan/report frameworks, traceability matrix development, and manufacturing-transition documentation for smoother progression into PVT while preserving design knowledge continuity.

✉️ info@lcdmodulepro.com

🌐 https://lcdmodulepro.com/

-

Exploring PVT ramps will help you grasp their importance in maintaining design intent and streamlining production. ↩

-

Understanding Design Validation Evidence is crucial for ensuring that product requirements are met effectively, enhancing quality and compliance. ↩

-

Understanding configuration management is crucial for ensuring consistent outcomes in projects, especially in DVT processes. ↩

-

Understanding DVT reports can enhance your knowledge of controlled learning and failure management in product development. ↩

-

Exploring these conditions ensures your products meet quality standards and enhances customer satisfaction. ↩

-

Explore this resource to learn how to craft impactful executive summaries that highlight key project insights and risks. ↩