Logistics sorting equipment requires LCD modules optimized for high duty cycles, harsh environments, and deterministic recovery rather than consumer-focused specifications.

Logistics sorting equipment runs long hours with fast operator workflows and tough conditions like dust, vibration, temperature swings, and EMI from motors and scanners. Displays sit on conveyors and stations where glare and off-axis viewing are common, so stable readability matters more than “peak specs.” Because downtime is costly, choose modules with strong power/interface margin, deterministic recovery, and lifecycle support for field replacement.

Logistics deployments punish weak assumptions. A display that looks fine on a bench can fail on a line when motor starts pull rails down, long harnesses shift ground reference, or vibration turns a marginal connector into an intermittent fault. The selection mindset should be “stable and recoverable,” not “highest resolution.” Start from the operator’s viewing reality, then check the system layers that trigger field tickets: power quality at the module connector1, EMI margin, cable/connector robustness, and service-time targets.

What makes logistics sorting equipment a special use case for LCD display modules?

Logistics sorting environments create unique operational demands requiring specialized display module selection criteria focused on reliability and environmental tolerance.

Sorting lines combine high duty cycles, frequent UI changes, and harsh stress: dust, continuous vibration, temperature cycling, and EMI from drives, actuators, and scanners. Displays may be mounted on moving frames or angled stations under bright industrial lights, so readability must stay consistent across angles and glare. Because throughput loss is expensive, prioritize deterministic behavior, robust power/interface margin, and long lifecycle and service strategies over consumer-style aesthetics.

Sorting sites amplify small weaknesses. Dust and debris complicate optics and seals, vibration challenges connectors and mounting flatness, and EMI plus power transients push interfaces and backlight drivers toward their margins. The right module choice is the one that stays predictable under these stressors, and that can be replaced quickly with minimal rework. Treat the display as part of an availability system: stable start-up, stable operation, and stable recovery.

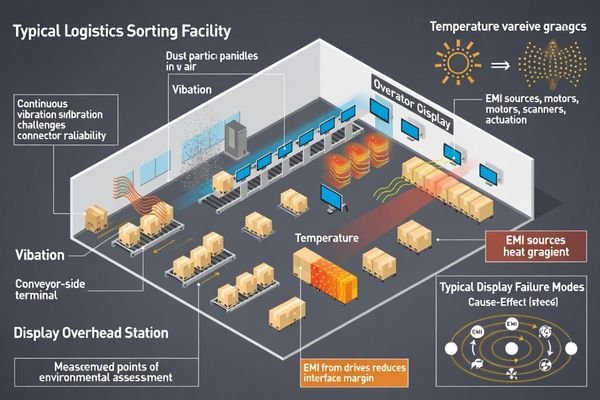

Environmental and Operational Stresses

Sorting facilities stress LCD modules2 through vibration, airborne contaminants, and electrical noise. Vibration can loosen latches or increase contact resistance, while dust and debris increase cleaning frequency and can degrade optical surfaces over time. Temperature swings shift electrical and optical behavior, especially for backlights and adhesives. EMI from motor drives and switching loads can reduce link margin, making “almost works” designs fail intermittently.

High Availability and Service Requirements

High availability means the display must recover deterministically from common site events: brief voltage dips, ESD/EMI upsets, and connector disturbances. Service design matters as much as selection—field techs need repeatable mounting, standardized harnessing, and a swap process that does not require realignment or recalibration. Lifecycle support is also critical: stable documentation, controlled revisions, and supply continuity reduce multi-site rollout risk and spare-part headaches.

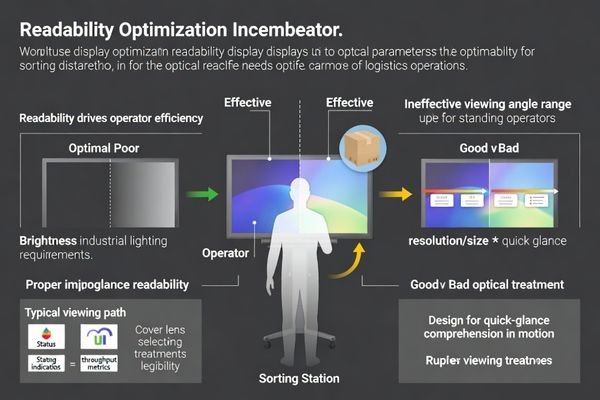

Which performance factors determine readability and operator efficiency?

Readability optimization requires balancing brightness, viewing angles, and response characteristics with the specific viewing conditions and operator workflows in sorting environments.

Readability on sorting lines is driven by brightness/contrast under glare, wide viewing angles for off-axis operators, and a size–resolution balance that keeps key UI elements legible at working distance. Response and refresh stability affect scrolling lists, alarms, and real-time throughput indicators, while consistent color helps status coding. Optical integration is equally important: cover lens choice, anti-glare/AR treatments, and mask margins that prevent distracting edge artifacts.

Operator efficiency depends on “instant comprehension.” A display that is technically bright but washed out by glare, or readable only on-axis, slows decisions and increases errors. Define readability targets in context: typical viewing distance, typical angles, and the lighting reality of the station. Then align UI choices3 (font size, contrast, alarm colors) with the module’s optical behavior and the cover-lens strategy, so the result remains clear during quick glances and continuous operation.

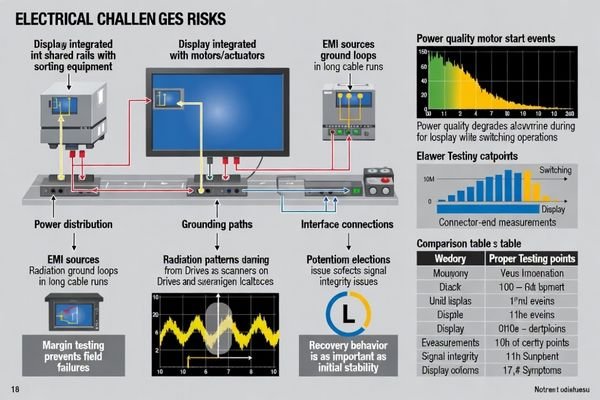

What electrical and interface risks are most common in sorting lines?

Electrical stability challenges in sorting equipment stem from power quality issues and electromagnetic interference that can disrupt display operation and communication reliability.

The biggest field risks are power and noise: shared rails with motors/solenoids, ground potential differences over long harnesses, and transient dips during peak loads that upset timing or trigger backlight protection. Interface problems often come from marginal signal integrity, vibration-driven connector intermittency, and EMI reducing link margin, causing intermittent blanking or artifacts. Select modules and architectures that support robust sequencing and deterministic recovery without full system reboots.

Most “random” display incidents aren’t random. They correlate with motor start/stop events, actuator switching, or cable motion. Design the selection and integration plan around measurable margins: connector-end voltage during peak events, clean reset/enable behavior, and interface stability with real cable length and routing. Also define recovery behavior: what gets reinitialized when a transient occurs, and how fast the UI returns to a known-good state.

| Risk Category | Common Manifestation | Root Cause Analysis | Mitigation Strategy |

|---|---|---|---|

| Power Instability | Intermittent blanking or reset | Voltage dips from motor loads | Dedicated supply rails and transient protection |

| Ground Loop Issues | Display noise or interference | Potential differences in long harnesses | Proper grounding scheme and isolation |

| EMI Susceptibility4 | Signal corruption or dropouts | Motor drives and actuator switching | Shielded interfaces and filtering |

| Connector Problems | Intermittent operation | Vibration-induced contact issues | Robust connector design and strain relief |

Systematic electrical risk assessment enables proactive design decisions that prevent field failures and reduce maintenance requirements while ensuring consistent display operation under normal sorting equipment conditions.

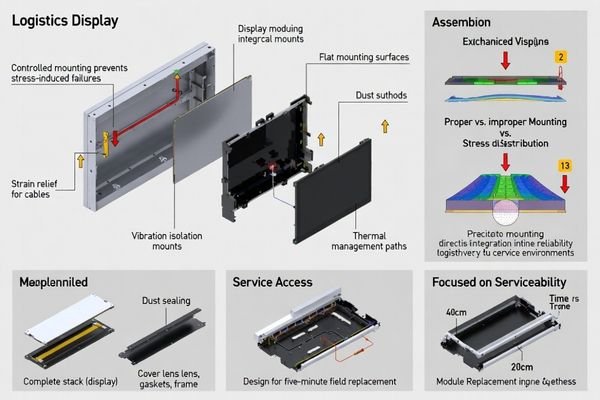

How do mechanical integration and protection impact reliability in logistics sites?

Mechanical design decisions directly influence LCD module survival and service accessibility in the demanding physical environment of logistics sorting operations.

Mechanical integration often decides field reliability: vibration isolation, strain relief, and mounting flatness reduce intermittent contacts and stress-related light leakage. Protection choices like dust sealing, cover lens hardness, and gasket design must balance ingress resistance with heat dissipation, especially in enclosed housings. Design for service speed with repeatable locating features and standardized harnessing so technicians can swap modules without rework or damage.

In logistics sites, mechanics and maintenance reality are inseparable. A connector that is electrically fine can still fail if the cable is allowed to flex at the contact point. A strong seal can still be a problem if it traps heat and accelerates drift. Aim for a “stable stack”: controlled clamping, controlled strain, controlled sealing, and controlled thermal paths, with a replacement process that is repeatable across multiple sites and technicians.

I’ve observed that mechanical integration often determines field reliability more than electrical specifications because sorting equipment subjects displays to continuous physical stress requiring robust mounting, protection, and service design. For complex logistics display integration requiring systematic mechanical design and protection strategy during sorting equipment development projects demanding reliable operation and efficient field service, engineering teams can contact info@lcdmodulepro.com when mechanical integration challenges require specialized expertise in vibration isolation5, environmental sealing, and service-optimized mounting solutions.

Vibration and Mounting Considerations

Vibration control starts with how the module is located and supported. Use stable locating features that prevent rotation, avoid point-loading that warps the stack, and ensure mounting flatness so stress does not translate into light leakage or connector movement. Add connector retention and strain relief so cable motion does not transmit force into contacts. Validate on representative structures, because conveyor frames and operator stations can have very different vibration signatures.

Environmental Protection and Thermal Management

Dust and debris protection usually requires a cover lens and sealing strategy, but sealing must be designed with heat in mind. High-brightness backlights and enclosed housings can raise internal temperature, so gaskets, vents, and material choices should preserve thermal headroom while meeting ingress goals. Choose surfaces that tolerate frequent cleaning without hazing or scratching, and verify that optical coatings remain effective under real lighting and contamination exposure.

How should you select and validate LCD modules for sorting equipment deployments?

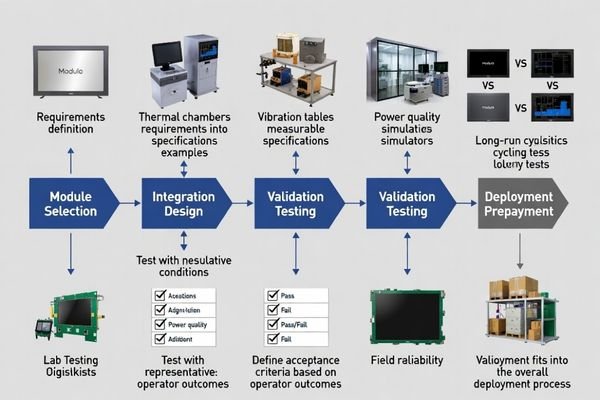

Systematic selection and validation requires translating operational requirements into measurable criteria followed by comprehensive testing under representative conditions.

Start from the operator scenario and environment, then convert it into measurable targets: luminance under real glare, viewing-angle needs, and UI legibility at working distance, plus a timing/interface plan with comfortable margin. Next, assess the system risks that drive field failures—power quality, grounding, EMI exposure, cable length, and vibration—and ensure predictable sequencing and recovery. Finally, validate with representative builds using thermal soak, vibration, power transient tests, long-run cycling, and acceptance criteria tied to visible outcomes.

Successful rollouts treat validation as a deployment rehearsal, not a lab exercise. Test the same cable lengths, routing, mounting, and lighting found on-site, and verify behavior during the events that trigger real failures: motor starts, actuator switching, and repeated operator interactions. Define “pass” in user-visible terms—stable readability, no intermittent blanking, and predictable recovery—so engineering results map directly to uptime and service cost.

Requirements Translation and Module Selection

Operational Analysis:

- Map operator workflows, viewing distances, and lighting/glare conditions to define legibility targets.

- Specify luminance goals for the actual station environment, not just “maximum brightness.”

- Set viewing-angle expectations based on mounting height and operator positions.

- Define service constraints (swap time targets, accessibility, and repeatable locating).

System Integration Evaluation:

- Check connector-end power during peak events (motor start, actuator switching) and confirm stable enable/reset behavior.

- Evaluate grounding and harness routing to reduce noise coupling and ground-potential issues over long runs.

- Confirm interface margin with the intended cable length and connectors under vibration and temperature variation.

- Define deterministic recovery paths6 (what to re-init, what to power-cycle, and acceptable recovery time).

Validation Testing and Deployment Preparation

Stress Testing Protocol:

- Thermal soak and cycling at representative enclosure conditions and brightness levels.

- Vibration testing that matches conveyor/station behavior, including connector retention checks.

- Power transient testing for dips, surges, and interruptions representative of the line’s loading.

- Long-run cycling across shift durations to catch drift and intermittent faults.

Acceptance Criteria Development:

- Tie thresholds to operator outcomes: stable readability under glare, consistent color/status visibility, no intermittent blanking.

- Verify mechanical alignment, sealing effectiveness, and repeatable mounting after rework or swap.

- Document recovery requirements and confirm they work without full system reboot.

- Create a site-ready checklist so multiple facilities can deploy consistently.

Customization Strategy:

- Optimize the optical stack for glare control, cleaning durability, and mask margin design.

- Design mounting and vibration isolation for the actual structure and service access constraints.

- Engineer harnessing for cable routing, strain relief, and connector reliability under vibration.

- Plan lifecycle support for spares, controlled revisions, and multi-site consistency.

FAQ

Do sorting lines usually need high-brightness LCD modules?

Not always, but they often benefit from higher luminance when installed under strong overhead lighting or near open loading areas; the right target depends on glare conditions and viewing distance.

What causes intermittent black screens in sorting equipment displays?

Common causes include connector-end voltage dips, noisy shared rails with motors, EMI reducing link margin, and connector intermittency under vibration; controlled recovery tests help isolate the layer.

Which interfaces are safest for long cable runs?

It depends on distance, environment, and architecture; the safest approach is to choose an interface with proven margin for your cable length and EMI profile and validate with connector-end measurements.

How do I prevent readability loss from glare and dust?

Combine sufficient brightness with optical treatments (anti-glare/anti-reflection), a well-designed mask border, and a cover lens strategy that supports cleaning without scratching.

What should I test before rolling out to multiple sites?

Validate thermal stability, vibration robustness, power transient tolerance, interface stability, and long-run cycling on representative builds, and confirm recovery behavior is deterministic.

When is customization worth it for sorting equipment displays?

When glare, mounting constraints, cable routing, sealing, or service-time targets are tight; customization can align optical stack, mechanics, and harnessing to real site conditions.

Conclusion

Choosing LCD display modules for logistics sorting equipment is less about maximum specs and more about stable readability, deterministic recovery, and long-life reliability under noise, vibration, dust, and high duty cycles. By translating operator needs into measurable optical targets, selecting interfaces with comfortable margin, and designing mechanics and protection for real site stress, teams can avoid intermittent failures and reduce downtime. A validation plan that mirrors deployment conditions—combined with customization where constraints are tight—creates displays that remain readable and serviceable across shifts and across sites.

MEIDAYINGNUO provides specialized LCD module selection and integration services for logistics sorting equipment requiring systematic evaluation methodology, environmental stress analysis, and deployment validation for harsh industrial operating conditions. Our engineering team offers comprehensive expertise in optical performance optimization, electrical stability assessment, mechanical integration design, and field validation testing ensuring display modules deliver consistent operation under the demanding conditions of logistics sorting facilities while maintaining cost-effective lifecycle management and service accessibility. Contact our logistics display specialists when sorting equipment challenges require expert module selection methodology and systematic integration support for reliable high-availability deployments.

✉️ info@lcdmodulepro.com

🌐 https://lcdmodulepro.com/

-

Understanding power quality at the module connector is crucial for ensuring reliable logistics deployments and preventing failures. ↩

-

Explore this link to understand how to choose LCD modules that withstand environmental stresses and ensure high availability. ↩

-

Exploring how UI choices affect user experience can help you design more intuitive interfaces that improve operator efficiency. ↩

-

Exploring EMI Susceptibility will provide insights into protecting your devices from interference. ↩

-

Exploring vibration isolation techniques can significantly enhance the durability and performance of logistics equipment. ↩

-

Exploring deterministic recovery paths can enhance system reliability and minimize downtime during failures. ↩