LCD response time determines pixel transition speed, with low temperatures significantly slowing liquid crystal dynamics and creating visible ghosting artifacts.

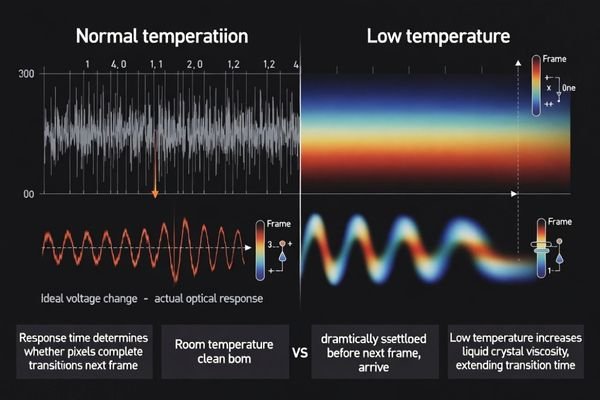

Response time is pixel transition speed (often gray-to-gray), while refresh rate is frame update speed. Low temperature slows liquid crystal dynamics, so pixels may not settle before the next frame—creating low-temperature ghosting and smearing that is especially visible in scrolling text, UI motion, and high-contrast edges. The fastest way to troubleshoot is to test gray-to-gray motion patterns at defined cold-start and steady-state temperatures, then evaluate whether overdrive and timing remain effective and stable across the temperature range.

In harsh-environment deployments, response-time issues often look “random” because teams validate only at room temperature, then see severe trails at cold start. Treat response time1 as condition-dependent and focus on repeatable tests: fixed temperature points, fixed motion patterns, fixed viewing distance/angle, and a consistent brightness level. Also avoid common pitfalls: judging only full-white or full-black screens, changing refresh rate and drive settings together, or testing after the module has already warmed up and masked the worst-case behavior. The goal is to translate “ghosting feels bad” into observable behavior tied to temperature, gray levels, and timing.

What exactly is "response time" in an LCD display module?

Response time measures the speed of LCD pixel optical state transitions following voltage changes, commonly focusing on gray-to-gray behavior.

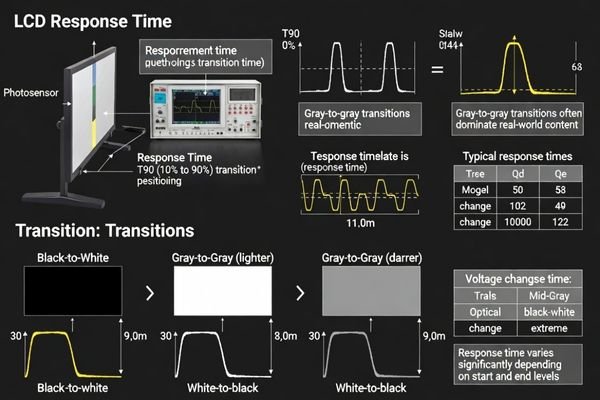

Response time describes how fast LCD pixels change from one optical state to another after driving voltage changes, commonly observed as time needed to transition between gray levels rather than only black-to-white switching. Real-world perceived response depends on the complete chain including liquid crystal material behavior, cell gap dimensions, temperature conditions, overdrive strategy implementation, and frame update timing because many interfaces and UI scenes contain mid-gray transitions where gray-to-gray behavior often matters more than headline marketing specifications.

Response time is best understood as “how long a pixel takes to reach its new level after a voltage change,” and it is not the same as refresh rate. Refresh rate controls how often new frames are shown; response time2 controls whether pixels actually reach the target before the next frame arrives. Because real UI and video contain constant mid-gray changes, gray-to-gray transitions often determine what users perceive. That’s why a single black-to-white number at room temperature rarely predicts motion clarity in the field.

Pixel Transition Dynamics

Pixel transitions depend on LC material behavior, cell structure, drive voltage steps, and temperature, all of which shape how quickly transmittance changes. Some transitions are inherently slower than others, and the direction matters (dark-to-bright can differ from bright-to-dark). This is why response time should be evaluated across multiple gray levels, not just extremes. When testing, keep timing and brightness fixed so you can attribute differences to the pixel dynamics.

Gray-to-Gray Performance Significance

Gray-to-gray behavior dominates because dashboards, UIs, and camera overlays rarely switch only between full black and full white. Mid-tones expose sluggish settling as smearing around edges and trailing shadows behind moving objects. A simple grayscale ramp and a moving edge pattern are often more revealing than static full-screen fills. If gray-to-gray is slow, ghosting will remain visible even when refresh rate is increased.

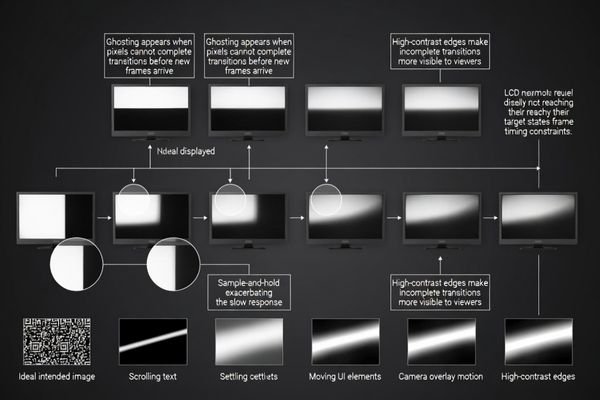

Why does slow response create ghosting, smearing, and motion blur?

Slow pixel transitions create visible artifacts when frames update faster than pixels can complete optical state changes.

Ghosting occurs when pixels have not finished transitioning before the next frame displays, creating displays that briefly contain mixtures of old and new states appearing as trailing shadows behind moving objects. Effects appear stronger in patterns with high-contrast edges, scrolling text, and repeating motion, varying by transition direction including dark-to-bright versus bright-to-dark changes and by gray level because LCDs function as sample-and-hold devices where slow transitions compound with frame persistence creating smearing that viewers interpret as motion blur.

Ghosting happens when the pixel is still “on the way” to the new level when the next frame arrives, so the eye sees a blend of old and new states as a trail. Smearing is the more continuous, paint-like tail you see during steady motion, especially on text and thin lines. Motion blur3 is a broader perception that also includes sample-and-hold persistence, but slow response makes it much worse by extending the transition. Practically, the faster the on-screen motion (or the higher the contrast edge), the more visible the timing mismatch becomes.

Why does low temperature make LCD response time much worse?

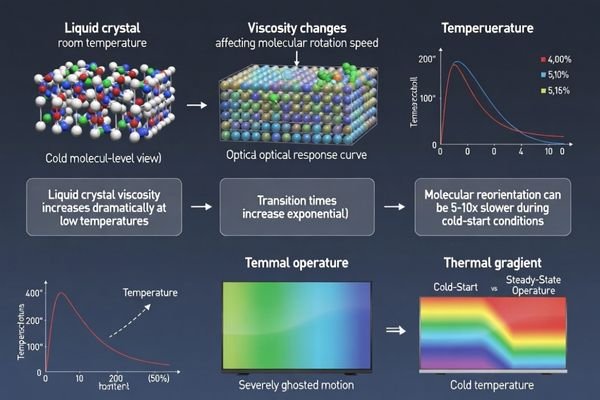

Low temperatures increase liquid crystal viscosity and slow molecular reorientation, dramatically extending pixel transition times.

At low temperatures, liquid crystal viscosity increases and molecular reorientation slows, requiring pixels to use more time reaching target transmittance after voltage steps. This can extend gray-to-gray transitions dramatically and shift balance between different transition directions, making some motion artifacts appear only in cold-start conditions while low temperature can also affect driver behavior and panel bias margins, though the dominant mechanism usually involves slowed electro-optical response of liquid crystal material itself.

Low temperature is a multiplier on response problems: gray-to-gray transitions4 can become dramatically slower, and direction asymmetry can increase, making some ghosting patterns appear only in the cold. This is why cold-start testing matters—steady-state after warm-up may look acceptable while initial minutes are not. Low temperature can also change electrical margins and bias behavior, but the most common practical cause is simply slower LC reorientation. If your product must be readable immediately at power-on in cold environments, validate that scenario explicitly rather than relying on warm lab tests.

| Temperature Effect | Physical Mechanism | Performance Impact |

|---|---|---|

| Viscosity Increase | Liquid crystal molecular mobility reduction | Extended gray-to-gray transition times |

| Molecular Alignment | Slower reorientation response | Asymmetric transition behavior |

| Drive Response | Voltage and timing parameter shifts | Altered overdrive effectiveness |

| Thermal Recovery | Gradual warm-up behavior | Transient performance variations |

Low-temperature response degradation requires systematic validation because artifacts may only appear during specific thermal conditions and motion patterns not captured in standard testing protocols.

How do overdrive, frame rate, and drive parameters affect low-temperature ghosting?

Drive optimization techniques require temperature-aware tuning to maintain effectiveness across operating conditions without introducing new artifacts.

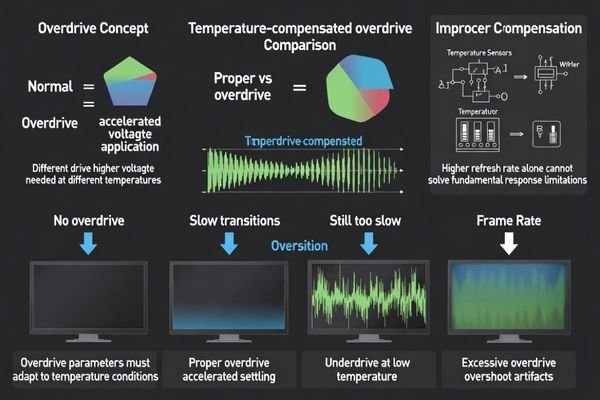

Overdrive aims to accelerate pixel transitions by applying stronger initial drive, but effectiveness and safety depend on temperature because required boost changes as response dynamics slow. If overdrive tables lack temperature compensation, cold conditions can produce underdrive with persistent ghosting or, when mismatched, overshoot artifacts and flicker-like edge halos while frame rate and scan timing also matter because higher refresh can reduce perceived motion step size but can also reduce available settling time per frame, making incomplete transitions more visible when response is slow.

Overdrive is often the key lever, but it must be temperature-aware: the “right” boost at room temperature may be too weak in the cold (underdrive) or too aggressive if mismatched (overshoot and halo artifacts). Frame rate changes can improve motion continuity, but they cannot make pixels settle faster; in some cases, higher refresh makes incomplete settling easier to notice because frames arrive sooner. The best results come from coordinating drive tables, bias margins, and timing so behavior remains stable across temperature and state transitions. For comprehensive temperature compensation analysis and drive parameter optimization during complex low-temperature ghosting troubleshooting, engineering teams can contact info@lcdmodulepro.com when systematic validation requires specialized expertise in temperature-dependent display performance optimization.

Temperature-Compensated Overdrive

Temperature-compensated overdrive adapts drive strength to the slowed dynamics in the cold, reducing ghosting without creating overshoot. Validate at multiple temperature points using the same motion patterns so you can see when the table becomes insufficient. Watch for edge halos and inversion-like artifacts as signs of excessive compensation. The goal is stable improvement across cold-start and steady-state, not a single “best-looking” condition.

Frame Rate and Timing Interactions5

Higher refresh can reduce visible step size in motion, but it also reduces the time between frames, which can expose incomplete transitions when response is slow. Keep frame rate changes isolated during testing and compare results at the same motion speed and brightness. Also consider scan timing and system stability in cold conditions—timing changes that are acceptable at room temperature may be marginal when electrical behavior shifts. Use repeatable clips and patterns so comparisons are meaningful.

How should you select and validate modules to minimize low-temperature ghosting?

Effective selection and validation require systematic testing under realistic temperature and motion conditions matching deployment requirements.

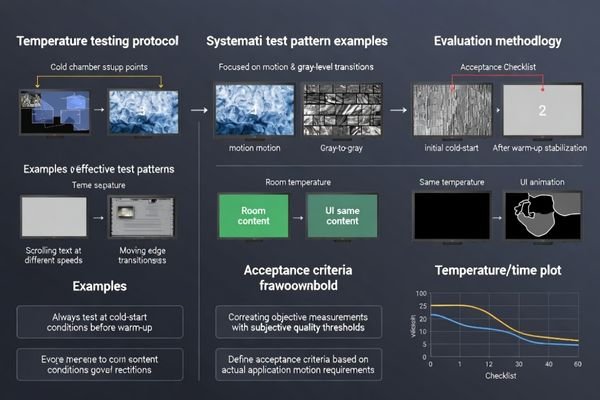

Module selection should start by defining real operating temperature ranges and motion patterns users notice most including scrolling text, moving indicators, camera overlays, or fast UI transitions, then evaluating response time under those conditions instead of relying on room-temperature specifications. Validation should include cold-start and steady-state tests with repeatable motion patterns, multiple gray levels, and different brightness settings while logging temperature and state transitions to capture worst-case behavior, prioritizing modules with proven low-temperature electro-optical performance and drive strategies supporting temperature-aware compensation.

Start with three concrete inputs: the minimum operating temperature, the motion patterns that matter most, and the acceptance threshold for ghosting/smearing under a defined viewing setup. Then validate with repeatable patterns: moving high-contrast edges, scrolling text, and gray-to-gray steps at multiple gray levels—run at cold start and again after warm-up at the same temperature setpoint. Log temperature, warm-up time, brightness level, frame rate, and any overdrive/drive mode used so the worst case is reproducible. If requirements are strict across wide temperature ranges, customization can align LC material choice, temperature-aware drive tuning, and acceptance criteria to keep motion performance consistent across batches and over product life.

Low-Temperature Ghosting Prevention Framework:

- Operating Condition Definition: Establish complete temperature range including cold-start and steady-state operation, identify critical motion patterns including scrolling text, UI transitions, and moving graphics, define acceptable ghosting and smearing thresholds for user experience requirements, document environmental factors affecting thermal behavior and response performance

- Validation Protocol Development: Create repeatable test patterns including gray-to-gray transitions and high-contrast edge motion, implement cold-start testing procedures with temperature logging and recovery characterization, establish measurement protocols for response time across temperature ranges and brightness levels, develop acceptance criteria linking response performance to visual quality requirements

- Module Selection Criteria: Prioritize liquid crystal material properties6 supporting low-temperature operation, evaluate overdrive and drive parameter temperature compensation capabilities, assess thermal design and power management stability across operating ranges, verify interface timing and signal integrity maintenance during temperature variations

- Customization Decision Framework: Consider customization when standard temperature compensation cannot meet motion clarity requirements, when application environments exceed typical module operating specifications, when batch consistency and lifecycle stability require specialized liquid crystal material selection, when systematic validation and acceptance criteria require custom drive tuning and optimization protocols

FAQ

Is response time the same as refresh rate?

No—refresh rate is how often frames are updated, while response time is how quickly pixels reach the new level after the update; slow response can cause ghosting even at high refresh.

Why is ghosting worse on gray backgrounds than on pure black or white?

Many gray-to-gray transitions are slower and more asymmetric, so incomplete settling is more visible in mid-tones, especially during scrolling content.

Can higher frame rate "fix" low-temperature ghosting?

It can help motion smoothness, but if pixels can’t settle fast enough in cold conditions, higher refresh may still show smearing and can expose incomplete transitions.

Does backlight brightness affect response time?

Brightness doesn’t directly change LC physics, but thermal state and drive strategies linked to brightness can change perceived ghosting, so test multiple brightness levels.

What tests best reveal low-temperature ghosting in real products?

Cold-start tests with scrolling text and moving edge patterns, plus grayscale ramps and repeating motion clips, measured at defined temperatures and after warm-up.

When should I consider customization for low-temperature motion performance?

When the application has strict motion clarity needs across a wide temperature range, and standard drive tuning can’t meet the acceptance criteria reliably.

Conclusion

Response time is pixel transition speed that determines whether motion settles cleanly before the next frame, and low temperature slows LC dynamics enough to make ghosting and smearing much more visible. Managing low-temperature ghosting requires looking beyond a single room-temperature specification and validating gray-to-gray behavior under cold-start and steady-state conditions with realistic motion patterns. With temperature-aware overdrive tuning, stable drive parameters, and clear acceptance criteria, teams can select or customize LCD display modules that maintain acceptable motion clarity across harsh environments.

MEIDAYINGNUO provides specialized low-temperature display optimization services including response time analysis, temperature-compensated overdrive development, and custom liquid crystal material selection for applications requiring consistent motion performance across demanding environmental conditions. Our engineering team offers comprehensive validation protocols including cold-start testing, gray-to-gray response characterization, and custom drive parameter tuning ensuring LCD modules maintain acceptable motion clarity throughout extended temperature ranges and complex deployment scenarios requiring reliable visual performance. Contact our technical specialists when low-temperature ghosting challenges require expert analysis and systematic optimization for harsh-environment display applications.

✉️ info@lcdmodulepro.com

🌐 https://lcdmodulepro.com/

-

Understanding the factors influencing response time can help improve performance in challenging conditions. ↩

-

Understanding response time is crucial for evaluating display performance, especially for gaming and video applications. ↩

-

Exploring motion blur will enhance your knowledge of display performance and help you make informed decisions. ↩

-

Exploring gray-to-gray transitions helps in grasping performance issues in displays, especially under varying temperatures. ↩

-

Learn about the impact of frame rate and timing on display quality, crucial for optimizing visual experiences. ↩

-

Exploring these properties can help in selecting the right materials for optimal performance in challenging conditions. ↩