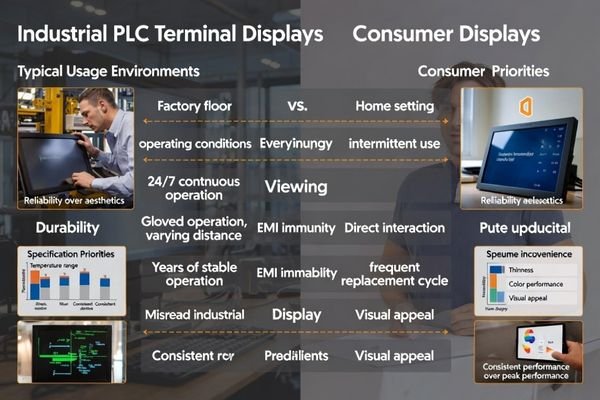

Selecting LCD modules for PLC-related terminals requires prioritizing industrial reliability, operator readability, and long-term consistency over consumer-focused performance metrics.

PLC terminal LCD modules must deliver stable readability under harsh industrial conditions including wide temperature ranges, electrical noise, extended operating hours, and glove-friendly interaction requirements. Selection criteria prioritize uptime reliability, viewing performance consistency, EMI resistance, and lifecycle continuity over thin profiles or advanced color performance.

In my LCD display module integration work at MEIDAYINGNUO, I’ve found that PLC terminal display issues often come from treating an industrial HMI1 like a consumer screen. In the field, a marginal design can turn into operator misreads, intermittent flicker, or random resets that stall a line and create hard-to-reproduce service calls. A practical selection flow is to (1) define the readability target under real factory lighting and viewing angles, (2) translate the environment into reliability requirements (temperature, vibration, static UI duty cycle, and expected lifetime), then (3) validate interface, grounding, and power-noise behavior under production-like EMI conditions. Finally, write procurement terms that lock measurement conditions and change control so replacement modules stay visually consistent. This approach reduces false rejects, prevents late-stage redesigns, and keeps the terminal maintainable across years of operation.

PLC terminals prioritize operational reliability and consistent readability over visual appeal under industrial operating conditions.

PLC-related terminals face wider temperature ranges, electrical noise from switching loads, long continuous operating hours, glove-friendly interaction requirements, and strict maintenance expectations. LCD modules must maintain stable brightness and contrast under factory lighting, resist EMI/ESD disturbances, and provide consistent viewing performance across varying operator distances and angles.

From an engineering standpoint, PLC terminals are production interfaces, not entertainment screens. A display fault can trigger misinterpretation, downtime, and expensive troubleshooting. That’s why selection should emphasize predictable behavior under stress, repeatable acceptance criteria, and lifecycle stability for spares—rather than thin bezels, extreme color gamut, or “best-looking” sample performance.

Industrial Operating Environment

PLC terminals must stay stable through temperature cycling, vibration, dust, and electrical disturbances that can quietly degrade displays over time. Define operating and storage targets, confirm backlight derating at the required brightness, and consider long-run thermal loading inside sealed enclosures. Treat EMI/ESD as a system condition: nearby motors, relays, and switching supplies can inject noise through cabling and grounds. Validation should look for flicker, intermittent resets, or interface instability under realistic noise and temperature rather than ideal lab setups.

Operator Interface Requirements

Industrial operators need fast, unambiguous readability—often from varying angles and distances, sometimes with gloves and protective gear. Prioritize high-contrast text rendering2, stable grayscale, and viewing-angle consistency so alarms and numbers aren’t misread. Glare control matters as much as brightness; a lower-brightness module with good reflection control can outperform a brighter one in practice. If touch is used, consider how cover lens, coatings, and adhesives affect readability, parallax, and acceptance criteria in the assembled state.

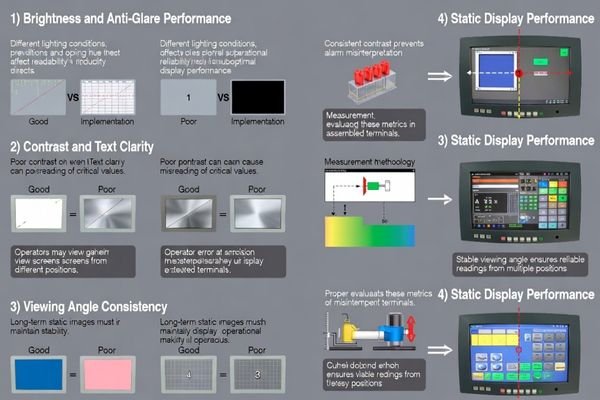

Which display performance requirements matter most for PLC terminals?

PLC terminal display performance should optimize operator readability and interface clarity under real industrial viewing conditions.

Critical performance requirements include brightness and anti-reflection strategy for readability under strong factory lighting, contrast stability and viewing angle consistency to reduce operator errors, response behavior optimized for clear text edges and stable grayscale rather than video performance, uniformity expectations, acceptable color appearance range, and dimming capability for varying ambient conditions.

Based on the projects I support with industrial HMI optimization, teams often discover that consumer-style specs don’t translate to factory readability. The practical requirement is not “best color,” but consistent interpretation of text, icons, and alarm states under glare, side viewing, and long static duty cycles. Define the viewing distance and angle range, set a glare/reflection strategy3 together with brightness, and state what “acceptable” uniformity and white appearance look like for operators. Also specify dimming behavior at the few brightness points that matter (day shift vs night shift, cabinet door open vs closed), and align inspection to the assembled cover lens/touch stack when that is how the product is judged.

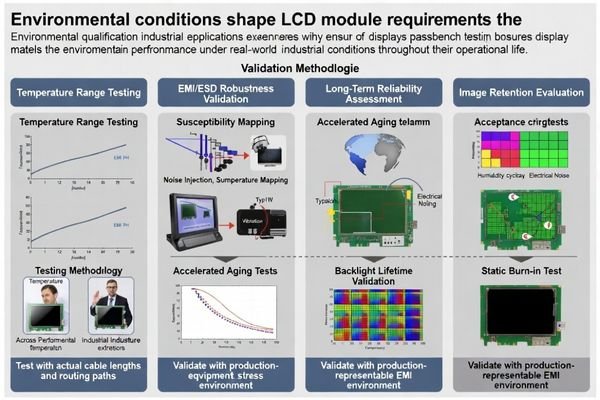

How do environment and reliability constraints shape module selection?

Environmental durability and long-term reliability requirements fundamentally change LCD module selection priorities for industrial applications.

Module selection must consider operating and storage temperature targets, backlight lifetime at required brightness levels with derating strategy, EMI/ESD robustness as system-level requirement including grounding strategy and cable routing, and reliability validation covering long-run burn-in behavior, brightness drift, image retention risk under static screens, and power interruption resilience.

When I troubleshoot PLC terminal field failures, environmental stress factors that seemed manageable during initial testing often accumulate over months of operation to create performance degradation that affects operator safety and production reliability.

| Environmental Factor | Module Impact | Selection Criteria |

|---|---|---|

| Temperature Cycling4 | Backlight degradation, optical stress | Wide operating range, thermal derating |

| Electrical Noise | Display artifacts, interface instability | EMI/ESD validation, robust grounding |

| Continuous Operation | Backlight lifetime, image retention | Long-term burn-in testing, static content validation |

Environmental constraints require module selection based on worst-case operating conditions rather than typical laboratory testing scenarios.

For comprehensive industrial display validation and environmental testing support, engineering teams can contact info@lcdmodulepro.com during specification development phases.

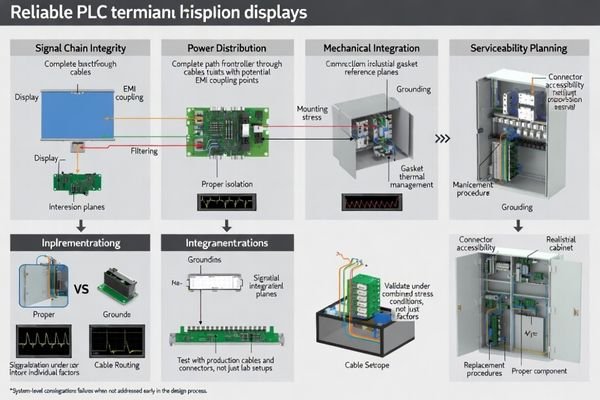

What interface and integration details prevent late-stage surprises?

System-level integration validation prevents common PLC terminal display problems that appear during production rather than development testing.

Critical integration details include bandwidth and timing budgeting with margin under production EMI conditions, complete signal chain validation including host, cable routing, connectors, and grounding, power integrity around backlight and logic rails to prevent switching noise modulation, mechanical integration controlling mounting stress and cover lens bonding, and serviceability planning for connector accessibility and spare part interchangeability.

I’ve observed that PLC terminal integration problems typically start when bench assumptions meet real installation constraints. Long routing paths, noisy cabinets, and mechanical stress can shrink margins and expose weak grounding or power integrity. To avoid late-stage surprises, validate the complete system under production-like EMI, temperature, and mechanical conditions, and define acceptance based on how the terminal is actually assembled and evaluated.

Signal Chain Robustness

Complete validation of the signal path5 must include the host output, cable/FPC characteristics, connector transitions, and the return-path/ground strategy. In PLC cabinets, routing often passes near high-noise wiring and switching supplies, so test under representative EMI and harness placement, not only in open-air lab conditions. Confirm timing and bandwidth headroom, and look for intermittent artifacts such as flicker, brief blanking, or re-sync events that may appear only during load transients. Production-like cable length and bend profiles should be part of the test setup.

Mechanical Integration Control

Mechanical stack-up choices can create visual defects even when the electronics are correct. Control mounting stress, gasket compression, and enclosure flatness so the module isn’t warped during assembly. If a cover lens or touch stack is bonded, define materials and process controls because adhesives, coatings, and pressure distribution can change perceived contrast and uniformity or introduce mura-like artifacts. Plan for vibration and service actions—repeated opening/closing or connector handling—so the assembly remains stable. Where inspection is done on the assembled unit, align acceptance criteria to the assembled condition.

Which LCD module options fit common PLC terminal form factors and use cases?

Industrial PLC terminals benefit from customized solutions that align mechanical constraints with operator interface requirements and environmental conditions.

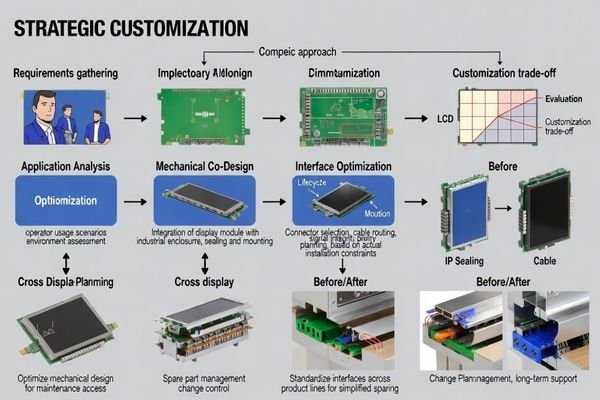

Module selection should prioritize customization when enclosure windows, mounting schemes, sealing strategies, and cable routing constraints don’t align with standard geometries. Customization-first approach locks HMI active area for operator readability, co-designs mechanical stack including bezel mounting and IP sealing, tailors interface and signal chain to host platform and routing constraints, and incorporates lifecycle-driven specifications for reliability and serviceability.

Based on my experience with PLC terminal projects, custom solutions consistently provide better long-term reliability and serviceability than attempting to adapt standard modules to industrial constraints that compromise signal integrity or mechanical robustness.

| Application / Scenario | Usage Pattern | Display Requirements | Recommended Model | Key Integration Considerations |

|---|---|---|---|---|

| Large Control Panel HMI | Multi-operator monitoring stations | High brightness, wide viewing angles | HB238X | EMI shielding, robust mounting, cable management |

| Compact Machine Interface | Single-operator local controls | Moderate brightness, touch-friendly | HB185X | IP sealing, vibration resistance, connector protection |

| Custom Industrial Shape | Specialized equipment integration | Application-specific geometry | Custom | Mechanical alignment, interface optimization, lifecycle support |

FAQ

Do PLC terminals usually need high-brightness LCD modules?

Only if the installation environment has strong ambient light or glare. Define the real lighting condition first, then choose brightness and reflection control together so you don’t overdrive the backlight and shorten lifetime unnecessarily.

How do I prevent image retention on static PLC HMIs?

Use a module and driving scheme validated for long static content, define acceptable retention criteria, and consider UI strategies such as periodic subtle refresh or element shifting when allowed by the application.

Should acceptance be based on the bare module or the assembled cover lens/touch stack?

Base acceptance on how the product is judged in reality. If the final product is evaluated assembled, align procurement and inspection to the assembled condition (or define a correlation method) to avoid false rejects.

What interface risks are common in PLC terminals?

Marginal bandwidth/timing, long or noisy cable runs, and poor grounding/power integrity can cause intermittent flicker, training failures, or resets. Validate the full chain under production-like EMI conditions.

How should I write lifecycle and change-control terms for modules?

Require notification and re-approval for changes to backlight, optical films, and key components; define spare-part interchangeability expectations and keep a master reference to manage lot-to-lot appearance drift.

When is "Custom" the best option for PLC terminals?

When your enclosure window, mounting, or cable routing constraints don’t match standard sizes, or when you need a specific active area and interface pinout to reduce risk and improve serviceability.

Conclusion

Choosing LCD modules for PLC-related terminals requires prioritizing operational reliability and long-term consistency over consumer-focused performance metrics. Success depends on defining requirements under realistic industrial conditions, validating complete signal and power chains under production-like EMI stress, and implementing procurement terms that control critical measurement assumptions and reliability targets. Understanding the fundamental differences between consumer and industrial display requirements enables selection decisions that maintain readability and stability across years of continuous operation.

MEIDAYINGNUO can support LCD module selection and integration validation for PLC terminal projects where industrial reliability is critical. Our engineering team can assist with system-level review of readability targets, EMI/ESD risk, thermal and lifetime considerations, and production-representative validation planning to help achieve stable operation across harsh environments and long lifecycles. Contact our technical team when PLC terminal display requirements need clearer industrial specifications and verification support.

✉️ info@lcdmodulepro.com

🌐 https://lcdmodulepro.com/

-

Exploring this resource will provide insights into effective design strategies for industrial HMIs, ensuring better performance and reliability. ↩

-

Exploring high-contrast text rendering can enhance operator interface design, ensuring clarity and safety in critical environments. ↩

-

This resource will help you understand how to minimize glare and reflections, enhancing visibility in various lighting conditions. ↩

-

Exploring this topic can help you mitigate risks associated with temperature variations in your systems. ↩

-

Understanding the signal path is crucial for ensuring optimal performance and reliability in electronic systems. ↩