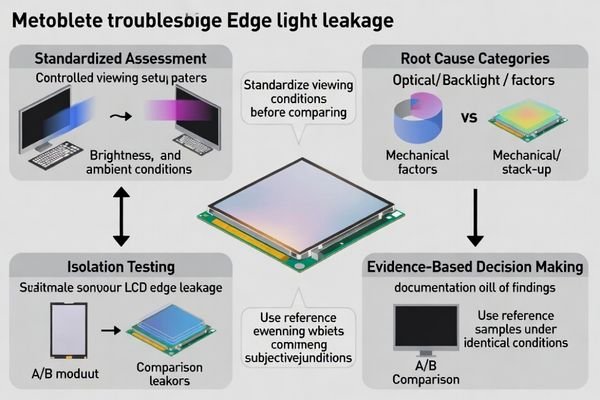

Edge light leakage troubleshooting works best when you first standardize how you judge leakage, then isolate whether the pattern follows backlight/thermal behavior or mechanical stress and stack-up variation. A structured workflow reduces false alarms, avoids unnecessary returns, and shortens time to root cause.

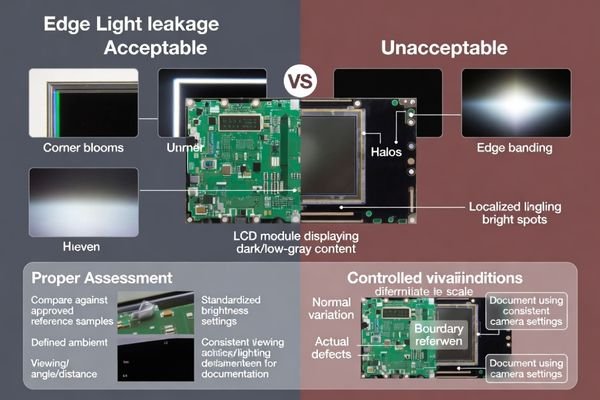

Edge light leakage is unwanted brightness escaping near the module perimeter, often seen as bright bands, corner blooms, or uneven halos on dark or low-gray images. It is a real problem when it exceeds the agreed acceptance boundary under defined viewing conditions, is visible in normal use (not only extreme dark-room checks), or signals mechanical stress that may worsen. Because perception depends strongly on brightness, pattern, ambient light, and viewing angle, start by locking a repeatable inspection setup.

Edge leakage is often misdiagnosed as a panel defect when the real driver is stack interaction: compression, mounting torque, gasket behavior, and backlight distribution under temperature and luminance changes. A good troubleshooting approach1 treats leakage as a measurable, repeatable condition and uses evidence (photos under the same setup, A/B checks, and reference builds) to avoid “memory-based” decisions.

What counts as "edge light leakage," and when is it a real problem?

Edge light leakage represents unwanted brightness escaping near module perimeters that becomes problematic when exceeding acceptance criteria or indicating potential reliability issues under normal viewing conditions.

Edge leakage becomes actionable only when judged under the same conditions used for acceptance. Define the test pattern (dark/low-gray), brightness level, ambient lighting, viewing distance/angle, and—if photos are used—camera exposure rules. It is a real problem when it exceeds the agreed boundary, is visible in normal operation, or indicates stress that could drift over time.

Subjective perception varies dramatically with setup. Before troubleshooting, confirm the issue is repeatable and not created by differences in brightness settings, pattern selection, ambient light, or camera exposure. Compare to a known-good reference (golden sample or approved baseline build) under identical conditions so the discussion stays grounded in agreed acceptance rather than personal preference.

Leakage Classification and Severity Assessment

Edge leakage manifests in various forms including corner blooms, edge banding, uneven halos, and localized bright spots, requiring systematic classification based on location, intensity, and viewing condition dependency to establish appropriate troubleshooting priorities2 and resolution strategies.

Problem Threshold Definition

Real problems occur when leakage exceeds specification limits, affects normal use perception, or indicates mechanical stress that may worsen over time, distinguishing between cosmetic variations within tolerance and actual defects requiring corrective action and root cause analysis.

Which root causes most commonly create edge leakage in LCD modules?

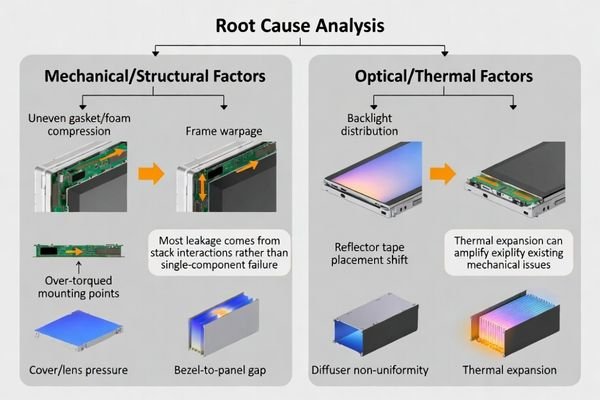

Edge leakage typically results from mechanical stack-up variations and backlight optical changes that affect light containment and distribution around module perimeters.

Most edge leakage comes from stack interactions rather than a single failed part. Common mechanical drivers include uneven gasket/foam compression, frame warpage, over-torque at mounting points, and cover/lens pressure that bends the stack and opens light paths. Common material/process drivers include foam thickness tolerance, adhesive creep, reflector tape placement shift, and bezel-to-panel gap variation. Optical/thermal factors may not create the light path, but they can amplify visibility through higher luminance, dimming behavior, and warm-up deformation.

A useful way to think about causes is by category: structure (frame flatness and mounting), materials (foam, adhesive, reflector), process (torque and alignment), thermal behavior3 (warm-up expansion and creep), and operating point (brightness and dimming). This framing helps teams prioritize checks instead of guessing. In many cases, leakage becomes noticeable only when a marginal mechanical condition is combined with a higher brightness setting or a warmer operating state.

How do you confirm whether the issue is backlight optics or mechanical stress?

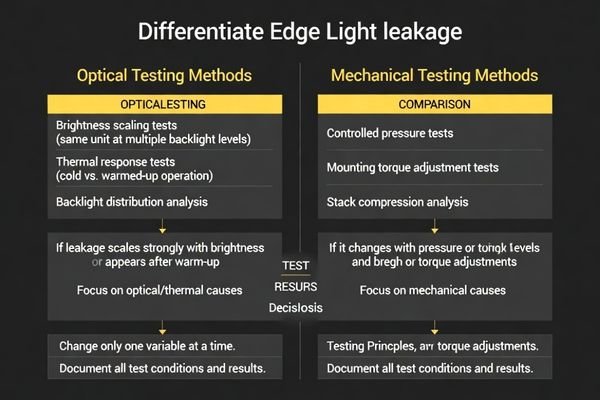

Systematic isolation testing differentiates between optical and mechanical causes through controlled brightness variation, temperature testing, and mechanical influence assessment.

Confirm the domain with controlled A/B tests. First, observe the same unit at multiple backlight levels, dimming modes, and temperatures; if leakage scales strongly with luminance or appears after warm-up, optics/thermal behavior is likely amplifying it. Next, check mechanical sensitivity using controlled, gentle changes—such as relaxing mounting torque or lightly altering edge pressure—while keeping the viewing setup fixed; if the pattern shifts, mechanical stress is a primary driver.

Cross-check visually for physical clues: frame gaps, uneven foam contact marks, tape displacement, or bonding stress that concentrates at corners. Then compare against a known-good reference build with the same stack and target assembly torque. If the issue follows the backlight subassembly4, optics alignment or diffusion is implicated; if it follows mounting conditions or stack compression, focus on the mechanical window and process control.

| Test Category | Isolation Method | Optical Indication | Mechanical Indication |

|---|---|---|---|

| Brightness Scaling | Multiple backlight levels | Leakage scales with luminance | Weak scaling; pattern fixed |

| Thermal Response | Warm-up behavior observation | Appears/increases after warm-up | Shifts with expansion/compression |

| Pressure Testing | Controlled gentle edge pressure | Minimal pattern change | Pattern shifts with pressure |

| Mounting Influence | Controlled torque adjustment | Little correlation | Direct pattern response |

| Reference Comparison | Known-good stack evaluation | Backlight distribution differences | Assembly/stack-up differences |

Systematic isolation testing enables accurate cause identification while preventing misdiagnosis that can lead to ineffective corrective actions and continued leakage issues during production and field operation.

What step-by-step troubleshooting workflow reduces rework and false conclusions?

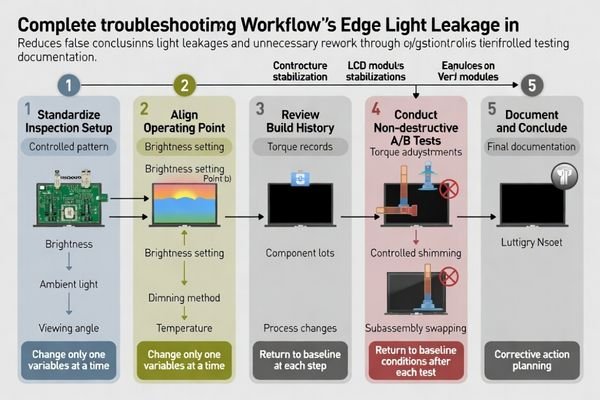

Systematic troubleshooting workflow progresses from standardized observation through controlled isolation testing to root cause confirmation preventing unnecessary rework and incorrect diagnoses.

Use a staged workflow that locks variables and produces evidence. (1) Standardize the inspection setup: pattern, brightness, ambient light, viewing angle/distance, and camera exposure rules. (2) Align the operating point: confirm brightness setting, dimming method, and temperature state for all comparisons. (3) Review build and change history: torque records, foam/gasket lot, tape placement, cover bonding process, and any recent deviations. (4) Run non-destructive A/B checks: torque relaxation, controlled shimming, or swapping a known-good backlight subassembly to see what the leakage “follows.” (5) Re-test under the same setup and document photos for a clear conclusion and corrective action.

A workflow only works if it prevents “setup drift.” Keep the same patterns and viewing setup, and record each step so the team can reproduce results. When changes are tested, change only one variable at a time and return to the baseline condition to confirm the direction of effect. This disciplined approach reduces rework because it avoids chasing symptoms that disappear once assembly or viewing conditions change.

Initial Assessment and Standardization Phase

Controlled Observation Setup:

Establish repeatable inspection conditions including consistent brightness settings, test patterns, ambient lighting, and viewing angles while documenting baseline leakage characteristics and comparing against specification limits and reference samples.

Preliminary Classification:

Document leakage location, intensity, and pattern characteristics establishing systematic baseline for subsequent isolation testing and ensuring consistent evaluation methodology throughout troubleshooting process.

Systematic Isolation Testing Phase

Optical Factor Testing5:

Evaluate brightness scaling, dimming response, thermal behavior, and backlight distribution effects through controlled parameter variation isolating optical contributions from mechanical influences and environmental factors.

Mechanical Influence Assessment:

Analyze mounting torque effects, edge pressure sensitivity, thermal expansion impacts, and assembly process variations determining mechanical contributions through controlled testing methodology without damaging test units.

How to choose or customize an LCD module to minimize edge leakage risk?

Edge leakage prevention requires systematic design optimization balancing optical performance with mechanical stability across expected operating conditions and assembly tolerances.

Minimizing edge leakage starts with aligning optical and mechanical stack to real mounting environment while controlling critical design parameters that affect light containment and mechanical stress distribution.

Design Optimization Strategy

Optical and Backlight Alignment:

Define target brightness and viewing conditions so the backlight diffusion and uniformity are matched to the required luminance without forcing extreme drive levels that amplify non-uniformity. Validate with dark/low-gray patterns at the intended brightness range, and confirm the backlight alignment and reflector placement remain stable across temperature and tolerance corners.

Mechanical Stack Control6:

Control gasket/foam geometry and compression windows, specify torque limits and mounting strategy, and avoid enclosure or cover-lens features that introduce bending stress at the perimeter. Ensure the design can tolerate normal assembly variation without opening light paths, and confirm that the stack remains stable after handling, vibration, and warm-up.

Customization Approach for Critical Applications

Stack Integration Optimization:

For tight cosmetic requirements, tune foam hardness, reflector placement, bezel gaps, and bonding stack as a complete system. This reduces the need for late “patches” and improves repeatability across lots by designing the compression and light containment behavior into the stack.

Process Control Enhancement:

Define assembly procedures, torque methods, and quality checks that keep compression even and alignment stable. Add change control for foam lots, tape placement, and bonding materials, since small shifts in these inputs can move a build from “acceptable” to “noticeable” leakage.

Validation and Qualification Requirements

Environmental Testing Protocol:

Validate with repeatable dark/low-gray patterns across temperature range and tolerance corners, including warm-up behavior. Confirm leakage remains within acceptance boundaries at the target brightness levels used in real operation, not only at minimum brightness.

Manufacturing Consistency Verification:

Include packaging and handling constraints so the stack does not shift or creep before installation. Monitor lot-to-lot variation with reference comparisons and trend checks to detect drift early, before edge leakage becomes a shipment or field issue.

FAQ

Why is edge leakage more visible on dark screens than bright screens?

Dark content has low image luminance, so any stray backlight escaping at the edges creates higher relative contrast and becomes easier to notice, especially in dim ambient light.

Can tightening screws reduce light leakage?

Sometimes, but it can also make it worse. Extra torque can warp the frame or over-compress gaskets, creating new light paths; controlled torque and even compression are more important than "tighter."

How do temperature changes affect leakage?

Temperature can change backlight output, diffuser behavior, and mechanical dimensions, so a marginal stack may look fine cold but leak after warm-up due to expansion or deformation.

Is edge leakage a sign of a defective LCD panel?

Not always. Many cases are assembly or stack-up related; confirm with controlled tests and reference builds before concluding the panel itself is defective.

What quick checks help avoid false alarms during inspection?

Use the same brightness, pattern, ambient light, and viewing angle every time, and compare against a golden sample under identical conditions to avoid "it looks different" due to setup changes.

When should we consider customization to solve leakage?

If leakage is sensitive to mounting stress, varies across lots, or can’t be stabilized with process controls alone, customization of foam, reflector, bezel gap, or bonding stack is often the most reliable long-term solution.

Conclusion

Noticeable edge leakage is usually a stack interaction issue—how backlight optics, compression, and mounting stress combine under real brightness and temperature conditions. Effective troubleshooting starts with repeatable inspection conditions, then isolates whether the leakage follows optical/thermal behavior or mechanical pressure/warpage using non-destructive A/B checks and reference builds. LCD Module Pro supports systematic leakage diagnosis, stack optimization, and customization so edge containment remains stable across tolerance corners and production lots.

LCD Module Pro provides comprehensive edge leakage troubleshooting and prevention services for LCD module applications requiring systematic diagnostic methodology, root cause analysis, and stack optimization across demanding optical and mechanical requirements. Our engineering team supports leakage analysis, process window definition, and customization approaches that improve repeatability and reduce recurring leakage disputes.

✉️ info@lcdmodulepro.com

🌐 https://lcdmodulepro.com/

-

Exploring effective troubleshooting approaches can enhance your methods for diagnosing edge leakage, ensuring more reliable results. ↩

-

Learning about troubleshooting priorities can help streamline the resolution process and improve efficiency in addressing display problems. ↩

-

Understanding thermal behavior is crucial for optimizing performance and preventing failures in engineering applications. ↩

-

Understanding the backlight subassembly is crucial for diagnosing display issues and improving product quality. ↩

-

This link will enhance your understanding of optical testing methods, crucial for optimizing display performance. ↩

-

This link provides insights on maintaining stability and performance in mechanical assemblies. ↩