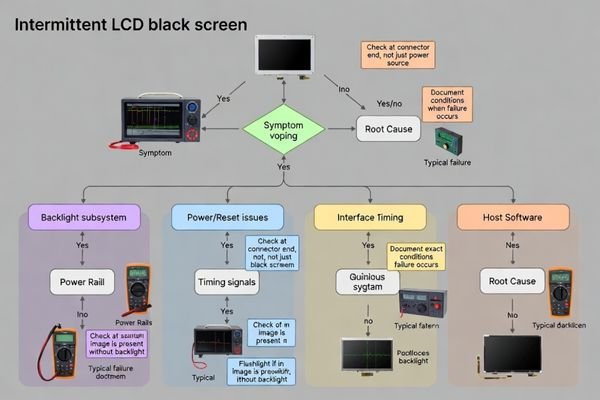

Occasional black screen symptoms require systematic diagnosis to distinguish between backlight failures, power instabilities, interface issues, and host software problems—and to avoid “fixes” that target the wrong layer. A reliable workflow is to classify the symptom first, validate the suspected layer with controlled recovery tests and connector-end measurements, then apply prevention changes that directly address the trigger.

Occasional black screens in LCD display modules can result from multiple failure modes including backlight driver shutdowns, power rail instabilities, interface timing margins, or software state problems. Effective troubleshooting requires systematic classification of symptoms, controlled recovery testing, power and signal integrity validation, then implementing targeted prevention strategies addressing the specific failure layer identified through diagnostic analysis.

In LCD display module integration work at MEIDAYINGNUO, occasional black screens1 frustrate teams because they feel random, yet most cases can be tied to specific, repeatable triggers once the symptom is classified correctly. The key is distinguishing between different failure modes that create similar “black” outcomes but require completely different measurements, recovery actions, and design changes. Treat the issue as a layered system problem—backlight, power/reset, interface/timing, or host state—then prove or eliminate each layer with evidence.

What does an "occasional black screen" actually mean in an LCD display module?

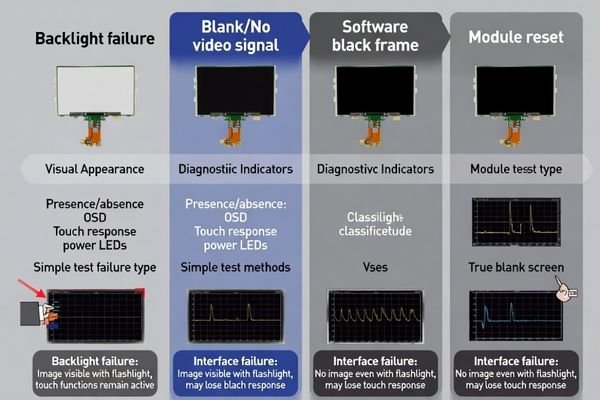

Black screen symptoms can represent multiple distinct failure modes requiring different diagnostic approaches and solutions.

Occasional black screens can describe backlight failures where panel receives valid video but illumination is absent, true blank conditions where panel is powered but receives no valid timing, software-generated black frames from host state issues, or intermittent module resets preventing initialization completion. Classification requires determining backlight status, OSD presence, touch response, and recovery method requirements to identify the affected signal chain layer.

From an engineering standpoint, precise symptom reproduction and classification prevents teams from spending weeks optimizing the wrong subsystem. A black screen that clears with backlight re-enable points toward illumination control or driver protection, while one that only clears after logic power cycling suggests reset/sequence or rail stability issues. If only a host reboot recovers the display, it still doesn’t “prove software”—it may simply be the only action that re-trains the link and re-applies the full initialization sequence. The fastest path is to label what exactly is missing at failure time: light, valid pixels, or stable initialization state.

Symptom Classification Methods

Start with a quick visibility check: if a strong flashlight reveals faint UI content, you likely have “no backlight2” rather than “no video.” Confirm whether the backlight enable, PWM/analog dimming input, and LED current are present when the screen goes black, and note whether touch or UI sounds still respond. If you have access to interface status signals (hot-plug, lock, error flags, or debug counters), record whether the link remains active. Most importantly, document the exact conditions when it happens (temperature, brightness level, vibration, power source, and time since boot) to turn “random” into a testable scenario.

Recovery Pattern Analysis

Use controlled recovery steps instead of a full reboot: try re-enabling the backlight only, then re-initializing the display interface only, then cycling only the LCD logic rail. The minimal action that restores the image is a strong clue to the failure layer and often reduces the search space by an order of magnitude. If recovery requires a full power removal, suspect an undefined state caused by reset glitches, latch-up events, or driver protection that does not auto-clear. Keep a simple log of “trigger → symptom → recovery action,” because repeated patterns frequently emerge after a few occurrences.

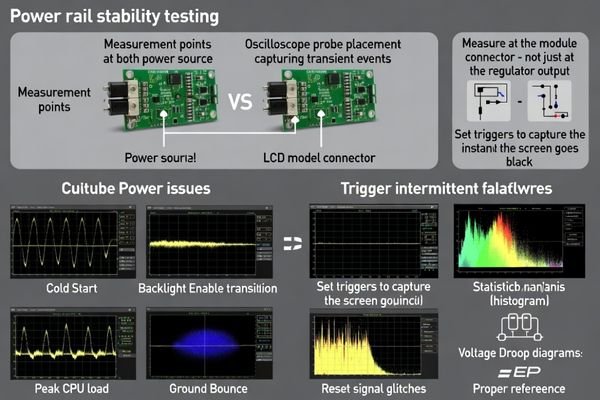

Is the power rail and reset sequence stable under transient loads?

Power rail stability and reset sequence integrity directly affect LCD module operation during transient conditions and system load variations.

Occasional black screens frequently result from brief undervoltage or brownout events affecting LCD module logic power, backlight power, or reset/enable pins without fully crashing the host system. Validation requires checking logic rail voltage tolerance at module connectors during worst-case conditions including cold start, peak backlight current, CPU load spikes, and hot-plug events while verifying reset and enable sequencing matches module requirements.

In field troubleshooting, power-related black screens often trace back to what the module actually sees at its connector rather than what the regulator reports at the source. A rail can look “fine” on the main board but droop at the display connector due to trace resistance3, cable losses, shared return paths, or fast load steps from the backlight. Reset and enable lines are equally critical: marginal pull-ups, slow edges, or EMI-induced glitches can push the module into an undefined state that only a true power cycle clears. Focus measurements at the connector under worst-case conditions (cold start, peak brightness, CPU spikes, and noisy supply transitions), and verify sequencing is deterministic—not “usually okay.”

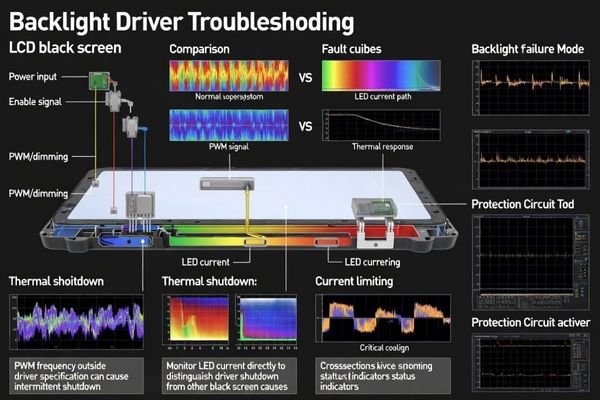

Could the backlight driver, dimming, or thermal protection be shutting the light off?

Backlight driver protection mechanisms and thermal management can cause intermittent illumination failures that appear as black screen symptoms.

Many black screen complaints actually represent backlight driver shutdowns caused by protection circuit activation, unstable LED current regulation, PWM or analog dimming compatibility issues, or thermal derating. Diagnosis requires confirming LED current presence during failures, enable pin status monitoring, driver fault state reading, and validation of PWM frequency, duty cycle ranges, and reference level compatibility with driver specifications.

Intermittent backlight issues are frequently revealed by the operating envelope: what works on a bench at room temperature may fail in a sealed enclosure, after warm-up, or under sunlight-driven thermal stress. Verify whether the “black screen” moment is truly a loss of illumination by checking LED current and the backlight enable state at the failure instant, then correlate it with dimming settings (PWM frequency, duty extremes, and signal noise). Some drivers behave poorly at very low duty cycles or with noisy PWM sources, causing repeated fault-trigger and shutdown behavior that looks random from the user’s perspective. For backlight driver validation and thermal margin optimization4 during complex intermittent troubleshooting, engineering teams can contact info@lcdmodulepro.com when systematic testing indicates a protection or thermal interaction.

| Protection Type | Trigger Condition | Recovery Method |

|---|---|---|

| Overcurrent Protection | LED string short circuit | Power cycle or fault clear |

| Thermal Protection | Driver overtemperature | Cooling and thermal design |

| Open String Detection | LED connectivity failure | String continuity repair |

| Input Undervoltage | Power supply instability | Supply margin improvement |

Backlight driver protection activation patterns help identify specific failure mechanisms requiring targeted corrective actions rather than general troubleshooting approaches.

Are the video interface, timing parameters, and physical interconnect robust enough against EMI and vibration?

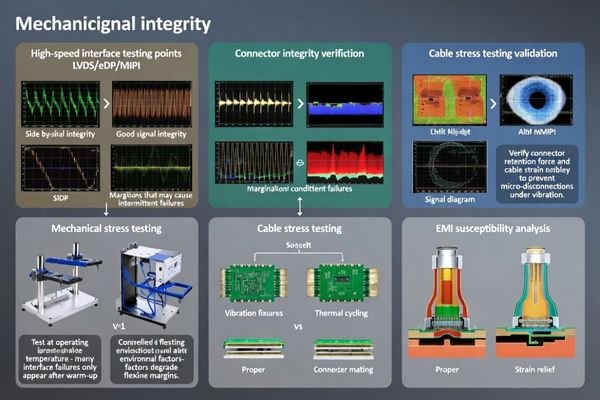

Interface signal integrity and mechanical stability directly affect intermittent black screen susceptibility under real operating conditions.

Intermittent blanking can result from marginal signal integrity on LVDS, eDP, or other high-speed interfaces, connector intermittency, FPC stress, or timing mismatches appearing after warm-up or under EMI exposure. Validation requires link margin measurement at connectors, impedance control verification, pair matching confirmation, reference plane continuity checking, and mechanical stress testing including connector latch integrity, cable bend radius compliance, and mounting tolerance verification.

Interface-related black screens often correlate with real-world stressors that do not appear in short bench tests: EMI from motors or power conversion, vibration-induced micro-movement at connectors, or thermal expansion that shifts contact resistance and signal margins. Because the symptom can resemble a software issue, it’s important to validate the physical and electrical link margin directly at the connector, where discontinuities and return path breaks are most likely to exist. Also confirm that the host does not inadvertently change timing parameters, refresh behavior, or initialization order during state transitions such as sleep/wake, hot-plug, or rapid brightness changes. If the failure is sensitive to movement, temperature, or nearby noise sources, treat it as a margin problem until proven otherwise.

Signal Integrity Validation

High-speed interface testing should include connector-end measurements where feasible, because that’s where impedance discontinuities5, reference plane breaks, and common-mode noise typically show up first. Confirm impedance control, differential pair matching, stable grounding/return paths, and any required filtering or shielding practices appropriate for the deployment environment. If failures occur after warm-up, consider that marginal timing or reduced eye margin can appear only at temperature extremes. Whenever possible, correlate black-screen events with link error indicators, retries, or training events to separate protocol instability from pure power/backlight issues.

Mechanical Stress Testing

Mechanical validation should target the conditions that create intermittent contact resistance: vibration, repeated handling, thermal cycling, and cable strain. Verify connector latch retention, cable bend radius, strain relief, and mounting tolerances so the interconnect does not experience micro-movement during operation. Check whether the issue is reproducible by gently flexing the cable or applying controlled vibration—if it is, prioritize mechanical reinforcement and connector selection. Mechanical robustness is often the “silent root cause” behind failures that disappear the moment a unit is moved back to the bench.

How do you design a "no-surprise" prevention plan for recurring black-screen risks?

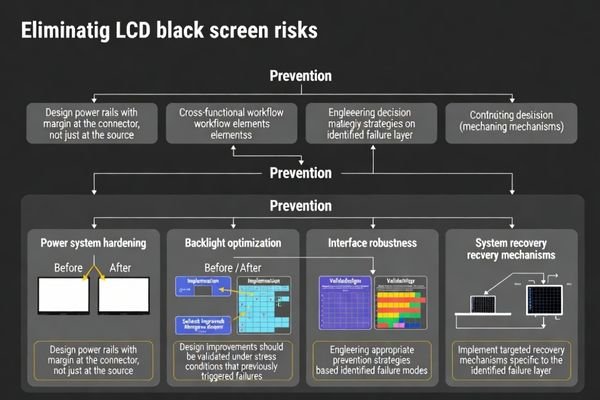

Prevention planning requires systematic hardening of identified failure layers rather than relying on recovery procedures for recurring issues.

Effective prevention converts identified triggers into systematic integration improvements including power integrity margin enhancement at connectors, noisy load isolation, deterministic reset and backlight enable sequence implementation, temperature-tolerant dimming strategy selection, EMI and ESD robustness improvement through grounding and shielding optimization, and system-level recovery mechanisms targeting specific failure layers through controlled re-initialization procedures.

Successful prevention plans treat occasional failures as measurable engineering risks6 rather than random user complaints. Once the dominant trigger is verified (rail droop, reset glitch, thermal derating, PWM incompatibility, link margin, or host state transitions), design changes should be applied at the layer that actually fails and validated under the same stress conditions that originally produced the symptom. The goal is predictable behavior: either the system never enters the failure state, or it can recover using a targeted action that is safe, repeatable, and test-verified. This approach reduces field returns because you are hardening the integration path that caused the instability rather than masking it with reboot rituals.

Black Screen Prevention Framework:

- Power System Hardening: Implement adequate power margin at module connectors, isolate noisy loads from display power rails, enhance decoupling capacitance near modules, and establish robust reset/enable sequencing with proper timing margins

- Backlight Optimization: Select temperature-stable dimming strategies, validate PWM parameters across operating ranges, implement thermal management for driver protection, and establish fault monitoring with controlled recovery procedures

- Interface Robustness: Optimize signal integrity through proper impedance control and grounding, implement EMI filtering and shielding strategies, enhance mechanical connector retention and strain relief, and establish link re-initialization capabilities for marginal conditions

- Custom Integration Solutions: Develop application-specific backlight designs, optimize interface timing for specific system requirements, implement custom connector and mounting solutions, and establish comprehensive validation testing under realistic operating stress conditions

FAQ

How can I quickly tell if it’s "no backlight" versus "no video"?

Shine a strong flashlight at an angle to the screen; if you can faintly see UI content, the panel is receiving video but the backlight is off. Also check whether the backlight enable and LED current are present when the failure occurs, and note whether touch or system audio still responds.

The screen recovers when I reboot the host—does that prove it’s software?

Not necessarily. A host reboot often toggles multiple things at once (logic power, reset, link training, and backlight enable). Try controlled recovery steps—re-enable backlight only, re-initialize the display interface only, or cycle only the LCD logic rail—to pinpoint the layer, then reproduce the issue under the same trigger conditions.

What are common power-related causes for intermittent black screens?

Connector-end voltage droop, shared rails with noisy loads, insufficient decoupling near the module, reset/enable pin glitches, and marginal backlight power capacity at cold start or peak brightness. Measuring at the module connector during transient events is often the fastest way to confirm or rule out rail instability.

Can EMI or ESD cause "random" black screens even if the design passes basic tests?

Yes. ESD can upset control lines or internal state without leaving permanent damage, and EMI can reduce link margin on high-speed pairs. Industrial environments often require stronger grounding, shielding, filtering, and layout discipline than bench tests reveal, so validate under realistic noise and cabling conditions.

Why does the issue appear only after warm-up or in a sealed enclosure?

Temperature shifts electrical thresholds and increases resistance, and backlight drivers may derate or trip thermal protection. Signal integrity can also degrade as materials expand and contact resistance changes, which is why thermal soak and enclosure testing are important for “intermittent” symptoms.

What information should I provide to get an engineering-level diagnosis?

A clear failure description and recovery method, power rail values at the module connector during failure, backlight enable/PWM details, interface type and timing settings, mechanical constraints, and the environmental conditions (temperature, vibration, EMI sources). If available, include a short event log showing trigger conditions and the minimal recovery action that works.

Conclusion

Troubleshooting occasional black screens becomes efficient when approached as a systematic layered problem requiring classification of backlight, power, interface, or software failures through controlled diagnostic testing and recovery analysis. Successful solutions focus on hardening the identified failure layer through power integrity improvement, stable backlight control, robust interconnect design, and targeted recovery mechanisms rather than relying on general troubleshooting or restart procedures. Prevention planning must address root causes through systematic integration improvements that eliminate triggers rather than managing symptoms through recovery protocols.

MEIDAYINGNUO provides specialized intermittent display failure analysis and prevention services for LCD applications experiencing occasional black screen issues requiring systematic diagnosis and custom integration solutions. Our engineering team offers comprehensive troubleshooting support including power integrity analysis, backlight driver optimization, interface signal integrity validation, and mechanical stress testing to identify root causes and implement targeted prevention strategies ensuring stable display operation under realistic deployment conditions. Contact our technical specialists when intermittent black screen issues require expert systematic analysis and custom engineering solutions for reliable long-term operation.

✉️ info@lcdmodulepro.com

🌐 https://lcdmodulepro.com/

-

Understanding the causes of black screens can help teams troubleshoot and prevent future issues effectively. ↩

-

Understanding the causes of ‘no backlight’ can help you troubleshoot display issues effectively. ↩

-

Exploring trace resistance will provide insights into its impact on circuit reliability and performance. ↩

-

Exploring thermal margin optimization techniques can significantly improve device reliability and performance under varying conditions. ↩

-

Understanding impedance discontinuities is crucial for ensuring signal integrity in high-speed interfaces, which can prevent costly failures. ↩

-

Exploring engineering risks management can enhance your knowledge on preventing failures and improving system performance. ↩