Brightness and uniformity validation requires controlled test conditions, systematic measurement protocols, and comprehensive analysis across thermal and operational variations.

Brightness and uniformity validation for high-brightness LCD display modules requires precise measurement conditions including controlled thermal states, standardized test patterns, defined measurement geometries, and systematic sampling protocols. Effective validation combines quantitative luminance measurement with spatial uniformity analysis across temperature and dimming variations to ensure consistent performance under real operating conditions.

High-brightness module validation needs more rigor than “single-point brightness checks,” because thermal rise, optical stack tolerances, and mechanical compression effects are amplified at higher luminance. The most useful output is a report that is reproducible and comparable across builds: a clearly defined luminance target1 (cd/m²), a uniformity metric (min/avg or min/max), a point map (or imaging map) showing where the extremes occur, and time/temperature data that proves stability from cold start to steady-state. Treat brightness and uniformity as linked behaviors that evolve with operating conditions—not static numbers—and your measurements will translate into design actions instead of debates.

What do "brightness" and "uniformity" mean for high-brightness LCD display modules?

Brightness and uniformity represent measurable luminance characteristics requiring precise definition of test conditions and measurement protocols.

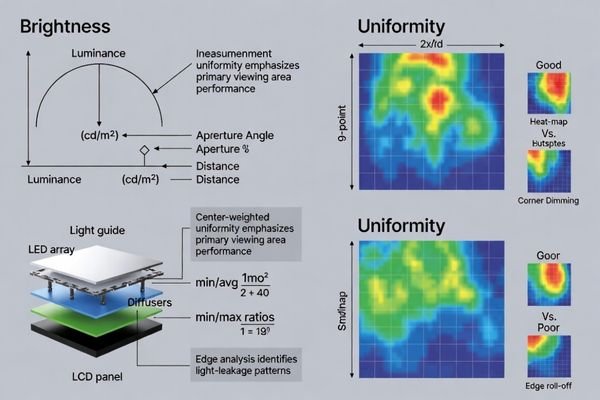

Brightness is measurable luminance emitted from the module expressed in cd/m² under defined conditions, while uniformity describes luminance distribution consistency across the active area and stability across time, temperature, and operating modes. For high-brightness modules, uniformity serves as both visual quality metric and reliability indicator because localized hotspots, edge roll-off, or corner dimming correlate with backlight optical stack behavior, mechanical compression, heat spreading, and current distribution.

To avoid “numbers that don’t match,” define the measurement state in the same sentence as the spec: test pattern level, dimming mode, viewing direction/measurement angle, warm-up time, and ambient setup. Also keep luminance (cd/m²) distinct from ambient illuminance (lux); mixing them is a common source of confusion when teams discuss “brightness” in bright environments. For high-brightness modules, uniformity should be reported with both a ratio and a location map, because two units can share a similar ratio while looking very different depending on whether the dim region sits in the user’s focal area.

Brightness Measurement Standards

Use a luminance meter or an imaging luminance system suited to the expected cd/m² range, and keep the measurement geometry fixed (distance, spot size/aperture, and angle). Set a standardized pattern (full white or specified APL) and lock the brightness command and driver mode so the same electrical state is measured each time. Control ambient light by using a dark environment or a consistent, documented illuminance level to avoid reflections and sensor bias. Record the full “recipe” with every measurement so results remain comparable across builds and time.

Uniformity Assessment Criteria

Define the uniformity formula2 (min/avg or min/max) and the sampling plan (for example, a 9-point or denser grid) as part of the acceptance criteria. Always include a map (point plot or imaging heatmap) showing where minima and maxima occur, because location often matters as much as ratio for user perception. If mura, banding, or edge roll-off is a concern, add a higher-density scan or imaging step to avoid missing localized defects. Keep viewing direction consistent, since off-axis measurements can change the apparent uniformity.

Which test conditions must be controlled to get repeatable brightness results?

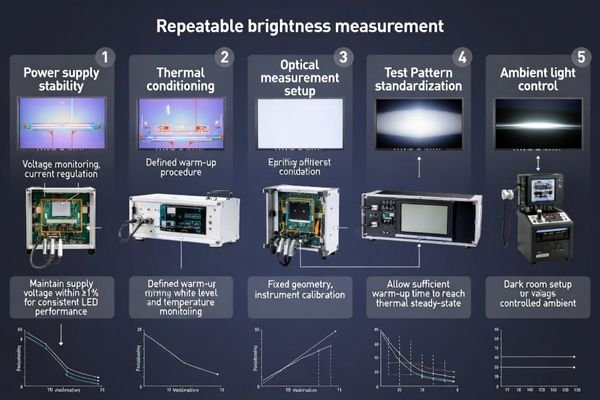

Repeatable brightness measurement requires systematic control of variables affecting luminance including power, thermal, optical, and environmental conditions.

Repeatability depends on controlling variables that strongly influence luminance including power and dimming settings, backlight driver mode, input timing and image patterns, optical measurement geometry, and thermal state with defined warm-up duration and steady-state temperature. High-brightness modules show particular sensitivity to temperature because LED efficacy and driver behavior shift with junction temperature, creating significant measurement differences between power-on and steady-state conditions.

Repeatable results come from eliminating “hidden variables3.” Fix the electrical state (supply tolerance, driver configuration, PWM frequency/duty or analog current command), fix the optical setup (distance and angle), and fix the content state (pattern and timing). Most importantly, fix the thermal state: define warm-up time and, during development, measure at multiple timestamps to identify when steady-state is reached. If the system includes any auto-brightness, thermal derating, or content-adaptive brightness behavior, disable it for baseline validation or document its behavior and test under clearly defined scenarios.

How do you measure uniformity across the active area without missing local hotspots?

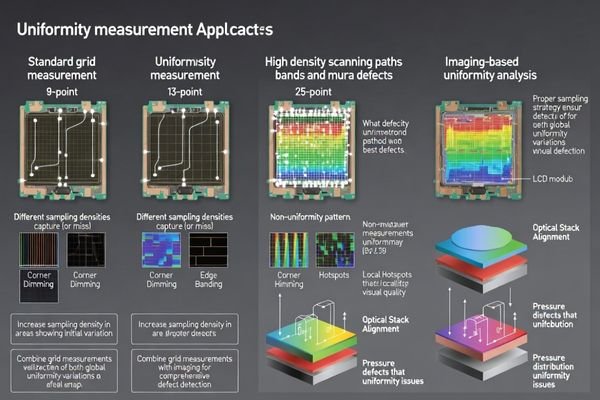

Uniformity measurement requires structured sampling protocols with sufficient spatial resolution to detect both global variations and localized defects.

Uniformity validation should combine structured sampling plans with adequate spatial resolution using grid measurements for global variation quantification and higher-density scans or imaging for localized non-uniformity detection including bright bands, mura, or edge light leakage. Sampling strategy should reflect actual usage patterns with center-weighted metrics for center-focused applications or comprehensive edge and corner analysis for full-area interfaces.

A practical approach is to pair a repeatable grid with a diagnostic map4. Start with a minimum grid that includes center, edges, and corners, then increase density or use imaging if the application is sensitive to banding or localized defects. Report a simple ratio for pass/fail comparisons, but also publish the point map so engineering can see whether the limiting region is a corner falloff, an edge leakage line, or a hotspot tied to current distribution. This prevents “good ratio, bad look” outcomes and helps correlate defects to optical stack alignment, mechanical pressure distribution, or thermal gradients.

| Measurement Approach | Spatial Coverage | Detection Capability |

|---|---|---|

| Grid Sampling | Center plus edge/corner points | Global variation quantification |

| High-Density Scanning | Comprehensive area coverage | Local hotspot and mura detection |

| Center-Weighted Analysis | Focus on primary viewing area | User-relevant uniformity assessment |

| Edge Analysis | Perimeter and corner emphasis | Light leakage and roll-off evaluation |

Reporting both simple uniformity ratios and diagnostic spatial maps helps distinguish between modules with similar numerical values but different visual appearance characteristics affecting user experience.

How do thermal effects and dimming modes change brightness and uniformity over time?

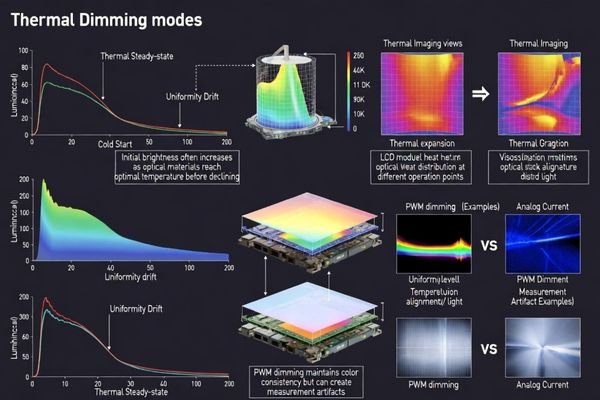

Thermal effects and dimming mode selection significantly impact brightness and uniformity behavior during extended operation.

High-brightness backlights generate substantial heat causing brightness and uniformity drift as optical stack and LED junction temperatures rise, sometimes improving initially as materials stabilize then degrading with strong thermal gradients. Dimming mode affects both measurement behavior and long-term stability with PWM maintaining peak current but potentially creating measurement artifacts while analog current dimming changes LED current directly, shifting chromaticity and efficacy affecting both luminance and uniformity.

Thermal behavior is often the difference between “passes once” and “stays consistent in the field.” Measure luminance and uniformity at defined time points from cold start through steady-state, and repeat at multiple brightness levels because some issues only appear at extremes (very low dimming or maximum drive). Dimming method matters: PWM can interact with certain instruments (aliasing) and also affects perceived artifacts, while analog current dimming can shift efficacy and chromaticity as current changes. Mechanical influences show up during warm-up—compression, light guide contact, and heat spreading can change corner falloff or banding patterns as the unit reaches thermal equilibrium. For expert thermal analysis and dimming optimization support during high-brightness module validation requiring complex measurement protocols, engineering teams can contact info@lcdmodulepro.com when systematic validation requires specialized thermal and optical expertise.

Thermal Drift Characterization

Define a time-based test (for example, multiple checkpoints from power-on to steady-state) and record module temperature alongside luminance and uniformity. Look for drift patterns: early stabilization, gradual decay, or localized changes that indicate growing thermal gradients. If possible, repeat under different ambient temperatures to confirm the behavior is robust and not a lab-only result. Use these curves to set realistic warm-up requirements and acceptance limits.

Dimming Mode Optimization

Validate PWM conditions with meter settings and sampling that avoid aliasing, and confirm results by repeating measurements with a compatible method when needed. For analog dimming, check multiple current levels for luminance linearity, chromaticity shift, and any uniformity changes that emerge at low drive. Ensure the chosen dimming strategy5 remains stable during transitions, since many field complaints occur when brightness changes rather than at steady state. Document the exact control parameters used so production and field teams can reproduce findings.

What validation workflow best supports customization and production consistency for high-brightness modules?

Effective validation workflows integrate optical targets with build variables and establish closed-loop processes for customization and production control.

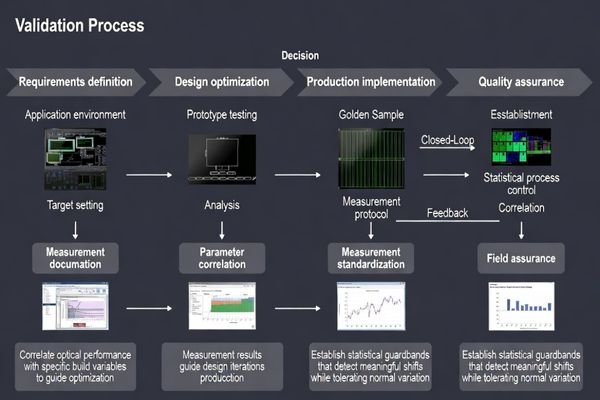

Optimal validation workflows establish closed-loop processes tying optical targets to build variables and acceptance criteria by defining brightness and uniformity metrics matching end-use conditions, locking down measurement recipes, running pilot builds correlating results with backlight current distribution, optical stack tolerances, and mechanical mounting pressures. Production consistency requires golden sample standards, instrument calibration protocols, and statistical guardbands accounting for normal variation while detecting shifts in light guide quality, diffuser alignment, LED binning, and driver behavior.

A strong workflow treats validation as a feedback loop, not a single gate. Start by aligning targets with end-use viewing conditions and ambient light expectations, then lock a measurement recipe that production can repeat. Use pilot builds to correlate measurement outcomes with controllable variables—optical stack alignment, current distribution, mechanical pressure, and thermal path—so design changes are guided by data rather than guesswork. For production, add golden samples, instrument checks, and statistical guardbands so normal variation is allowed while meaningful shifts are detected early. Finally, include stress-relevant verification6 (thermal soak, vibration, long-run) to ensure “meets spec today” does not become “drifts in the field.”

High-Brightness Module Validation Implementation Framework:

- Customization Optimization Phase: Define application-specific brightness and uniformity targets matching viewing conditions, ambient light environments, and UI content characteristics, establish measurement protocols reflecting real usage patterns, correlate optical performance with backlight design parameters including current distribution and optical stack configuration

- Build Correlation Analysis: Execute pilot builds with systematic measurement across design variations, analyze correlation between optical results and build variables including mechanical compression, thermal management, and component tolerances, establish design sensitivity understanding for optimization guidance

- Production Consistency Controls: Implement golden sample standards with calibrated measurement equipment, establish statistical process control with appropriate guardbands for normal variation detection, develop quality gates detecting shifts in component performance including light guides, diffusers, LEDs, and driver circuits

- Robustness Validation Testing: Conduct stress-relevant testing including thermal soak cycles, mechanical vibration exposure, and extended operation validation, verify long-term stability under realistic deployment conditions, establish field correlation protocols ensuring laboratory validation translates to real-world performance consistency

FAQ

What luminance target should I specify for a high-brightness module?

Specify the target in cd/m² along with the test conditions (white pattern level, dimming mode, measurement angle, warm-up time, and ambient light), because the number alone is not comparable without the recipe.

Is uniformity best expressed as min/avg or min/max?

Both are used; min/avg is often more stable for comparisons, while min/max can highlight extreme hotspots—use the metric that aligns with your acceptance strategy and include a map for context.

How long should I warm up before measuring?

Use a fixed warm-up time that reflects your product’s thermal behavior and measure at multiple timestamps during development to identify when steady-state is reached.

Can PWM dimming affect measurement results?

Yes—some instruments can alias with PWM; ensure the meter settings and sampling are compatible, or validate with an appropriate method for PWM conditions.

What is the most common root cause of poor uniformity in high-brightness modules?

It’s often a combination of optical stack alignment and mechanical pressure distribution, which can create edge roll-off, banding, or localized mura that changes with temperature.

How do you set production acceptance to avoid field drift?

Use controlled test conditions, golden sample correlation, statistical guardbands, and add thermal/time-based checks so units that drift with heat are caught early.

Conclusion

Validating brightness and uniformity on high-brightness LCD display modules requires systematic measurement protocols with controlled test conditions and comprehensive sampling methods designed to capture both global variations and localized defects. Effective validation must account for thermal effects and dimming mode impacts on long-term stability because high-brightness operation magnifies temperature-dependent behavior patterns affecting optical performance. Success depends on treating validation as an integrated design process linking measurement results to build variables rather than simple pass/fail criteria.

MEIDAYINGNUO provides specialized brightness and uniformity validation services for high-brightness LCD applications requiring precise optical performance measurement and systematic quality control processes. Our engineering team offers comprehensive validation support including customized measurement protocol development, thermal and dimming optimization analysis, production consistency framework implementation, and long-term stability verification ensuring high-brightness modules meet demanding performance requirements across varying operational conditions and extended deployment periods. Contact our technical specialists when high-brightness validation requires expert optical measurement analysis and systematic quality assurance for reliable performance consistency.

✉️ info@lcdmodulepro.com

🌐 https://lcdmodulepro.com/

-

Defining a luminance target is crucial for achieving optimal display performance; explore resources to refine your approach. ↩

-

Learn about the uniformity formula to grasp its significance in assessing display quality and user experience. ↩

-

Understanding hidden variables is crucial for achieving repeatable results in experiments, making this resource invaluable. ↩

-

Understanding diagnostic maps can enhance your knowledge of measurement techniques and improve defect analysis. ↩

-

Choosing the right dimming strategy can enhance lighting quality and energy efficiency. Discover expert recommendations here. ↩

-

Exploring this topic will help you ensure product reliability and performance under real-world conditions. ↩