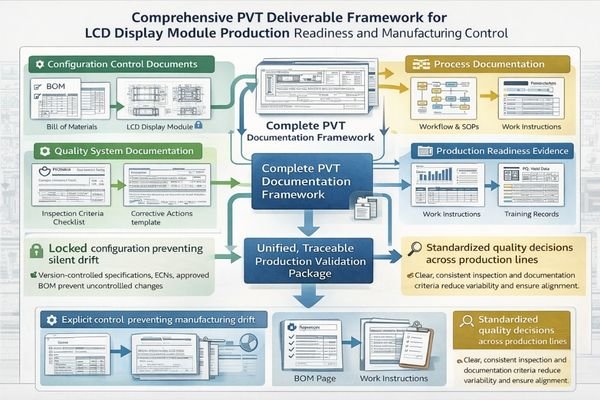

PVT deliverables are the proof that the product is ready to ramp: the configuration is locked, the process is repeatable on production-intent equipment, and quality decisions are standardized with stable yield evidence. A good PVT package prevents silent drift by tying every build and result to controlled documents, inspections, and change control.

PVT deliverables prove production readiness: a locked build configuration, repeatable production-intent processes, and standardized quality evidence with stable yield. For LCD display module integration, they control optical/mechanical sensitivity, define inspection and disposition rules, and keep manufacturing comparable across lines, batches, and suppliers.

In many LCD display module ramps, the biggest risk is not missing functionality—it is variation. Operator choices, equipment drift, material lot differences, and small unapproved substitutions can shift appearance or performance without being noticed until yields move or customer complaints appear.

A review-ready PVT package1 reduces that risk by making the manufacturing baseline auditable: it defines what to build, how to build it, how to inspect it, how to handle failures, and how changes are approved and traced. The goal is comparability: results from different builds and lines must mean the same thing.

What is the real purpose of PVT deliverables?

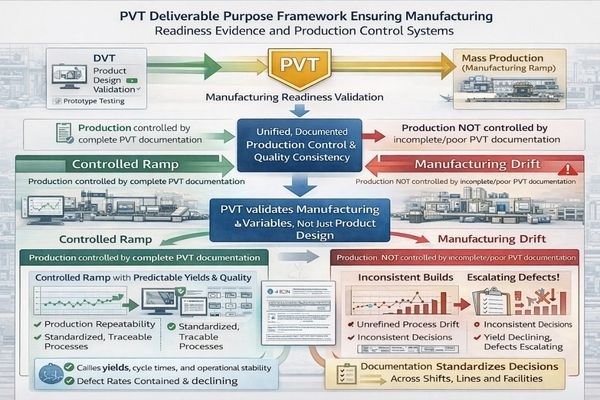

PVT deliverables demonstrate manufacturing readiness through production-intent evidence rather than design validation, proving repeatable builds with controlled quality systems.

PVT deliverables exist to prove the product can be built repeatedly with stable quality and predictable yield using production-intent processes and controls. They standardize what to build, how to run the process, how to inspect results, and how to disposition failures. For LCD display module integration, this discipline protects optical appearance and performance from drift during ramp.

PVT is where manufacturing variables become first-class citizens. Unlike earlier phases, you are validating not only the product, but the line’s ability to reproduce it. That requires documents that define the manufacturing recipe, the inspection logic, and the rules that prevent ad-hoc decisions when reality deviates from expectation.

Manufacturing Readiness Evidence

Manufacturing readiness evidence shows that key stations can run within defined limits and still produce acceptable product. This includes documented process controls, repeatability indicators (yields by station across builds), and clear acceptance criteria that do not depend on who is judging the unit.

Production Control System Validation2

A production control system is validated when it can detect drift early and force consistent decisions. That means standardized inspection methods, defined defect taxonomy, clear MRB disposition rules, and traceability that links units to lots, revisions, and deviations.

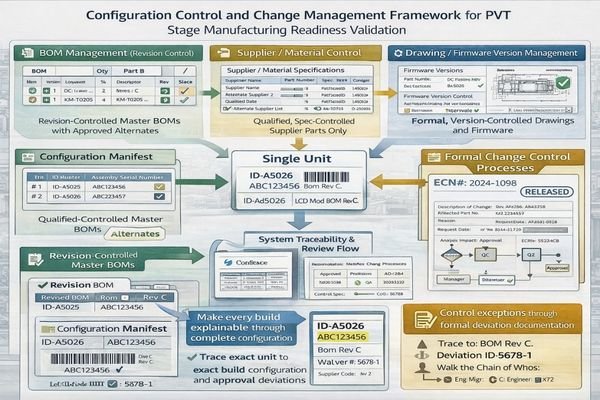

Which configuration, BOM, and change-control documents must be locked for PVT?

PVT requires strictly controlled configuration documentation preventing silent drift through comprehensive change management and traceability systems.

Lock the PVT configuration so every build is explainable: released BOM with approved alternates, supplier/material specifications, and a configuration manifest tying each unit to drawing and firmware revisions (and calibration parameters if applicable). Enforce change control with approved ECNs, deviation/waiver rules, and lot/date traceability so substitutions or exceptions cannot introduce silent drift during ramp.

In production-intent builds, “small” changes are often the ones that hurt: an alternate material, a different adhesive lot, or a component substitution can shift appearance, margins, or long-run stability. Configuration control at PVT3 should make such changes visible, reviewable, and traceable. If a unit differs from baseline, the documentation should show why, who approved it, and what evidence supports the exception.

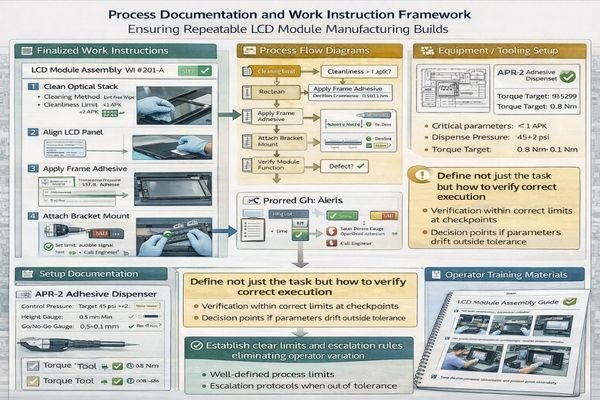

What process and work-instruction documents make builds repeatable?

Repeatable builds require finalized process documentation including work instructions, control parameters, and verification checkpoints eliminating operator variation.

Repeatability depends on finalized work instructions, process flow, tooling/equipment setup sheets, and critical process parameters with control limits and verification checkpoints. For LCD module builds, include controls for mounting pressure/torque, adhesive dispense and cure profiles, cleanliness and ESD handling, and any optical stack or backlight-related assembly steps. Define escalation and stop-the-line rules when steps are out of tolerance.

Work instructions should not only say “do X,” but also “how to verify X happened correctly.” Add objective checkpoints at the stations that matter most, and specify what operators must do when results are out of tolerance. This removes improvisation and reduces shift-to-shift variation.

| Process Category | Critical Documentation | Control Requirements |

|---|---|---|

| Assembly Procedures | Work instructions with photos/diagrams | Pressure/torque limits, sequence control |

| Optical Stack Assembly | Cleanliness protocols, handling procedures | Contamination prevention, alignment verification |

| Adhesive Application | Dispense patterns, cure profiles | Temperature/time control, thickness verification |

| Final Test and Inspection | Test procedures, acceptance criteria4 | Calibration requirements, sampling plans |

Use this table as a cross-check: if a process category is sensitive to variation, it should have both a “how-to” and a “how-to-verify” document with clear limits and escalation rules.

What quality, inspection, and test records prove production readiness?

Production readiness requires complete quality evidence including inspection criteria, test procedures, and defect management systems demonstrating controlled manufacturing capability.

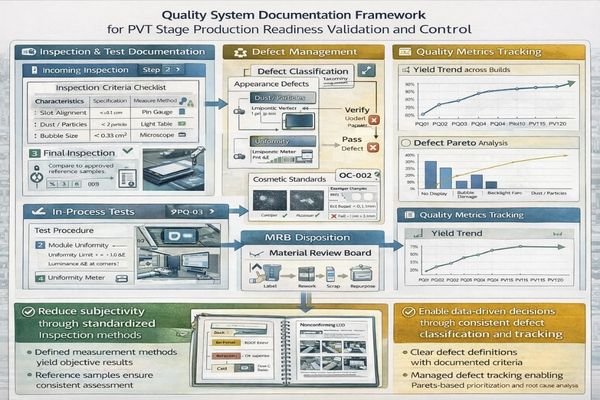

PVT quality deliverables include incoming and in-process inspection plans, final test procedures, sampling plans, and acceptance limits aligned to customer-visible performance. Add defect taxonomy and cosmetic standards, plus standardized MRB disposition workflows (rework/retest rules). Yield trends, defect Pareto, measurement method definitions, and lot/serial traceability prove the line can detect issues and control variation.

Quality systems fail when decisions depend on individual judgment. PVT documentation5 should reduce subjectivity by defining what “good” looks like, how to measure it, and how to handle deviations consistently. For appearance-sensitive products, align cosmetic standards with representative samples and controlled viewing conditions so the same unit is judged the same way across shifts and sites.

Inspection and Test Documentation

Inspection criteria and test procedures should specify the measurement method, acceptance limits, calibration requirements, and sampling rules. When a test fails, the documentation must define whether the unit can be reworked, how rework is verified, and what triggers escalation.

Defect Management and Traceability Systems

A usable defect taxonomy reduces debate and speeds closure. Pair it with traceability records (lot/date codes, serial mapping, deviation tags) so you can correlate defects with material lots, process windows, and configuration revisions during ramp.

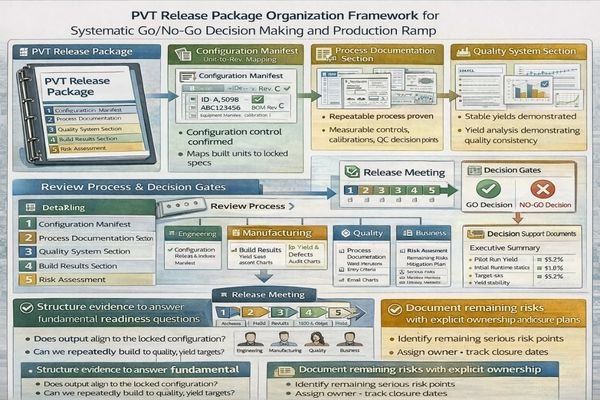

How do you package PVT deliverables into a go/no-go release set?

PVT release packages require systematic organization enabling confident go/no-go decisions through comprehensive manufacturing readiness evidence and risk assessment.

A PVT go/no-go release set should answer: what configuration is released, is the process controlled, and are yields/quality metrics stable with a plan for remaining risks? Package a release index and configuration manifest, then the process set (final WIs, flow, tooling setup, control limits), the quality set (inspection plans, test procedures, defect/cosmetic standards, MRB and rework rules), and the build results (yield trends, top defects, corrective actions, deviations). Close with an open-issues log with owners/dates and a ramp-window change freeze rule.

To keep data comparable, avoid “improving” the process mid-ramp without formal change control. If a change is necessary, document the before/after configuration, the approval, and the evidence that the change did not invalidate prior conclusions. This is the difference between a controlled ramp and a moving target.

Release Configuration Management

Configuration Definition and Control:

- Complete BOM with approved alternates and supplier specifications tied to exact revision levels

- Configuration manifest linking PVT builds to specific drawings, firmware, and calibration parameters

- Change control documentation including approved ECNs and deviation/waiver rules with clear approval processes

- Traceability systems connecting lot/date codes to build configurations ensuring explainable production units

Process and Quality Documentation Package

Manufacturing Process Definition:

- Finalized work instructions with clear verification checkpoints and escalation procedures

- Complete process flow documentation including equipment setup and tooling requirements

- Critical process parameters with defined control limits and monitoring requirements

- Operator training materials and competency verification ensuring consistent execution

- Comprehensive inspection plans covering incoming, in-process, and final testing requirements

- Standardized test procedures with calibration requirements and sampling plans

- Defect taxonomy and cosmetic standards with representative samples and disposition rules

- MRB processes and rework instructions ensuring consistent nonconformance management

Production Readiness Evidence

Build Performance Data:

- Yield trends by station and overall yield performance across multiple PVT builds

- Defect Pareto analysis identifying top failure modes with corrective action effectiveness

- Process capability studies demonstrating statistical control of critical parameters

- Measurement system analysis proving gage capability and repeatability for quality decisions

Risk Assessment and Mitigation:

- Open issues log with explicit ownership, mitigation plans, and completion deadlines

- Risk assessment covering remaining technical, process, and quality concerns with mitigation strategies

- Change freeze protocols ensuring stable baseline maintenance during production ramp window

- Escalation procedures for handling deviations and unexpected issues during volume ramp

FAQ

How is PVT documentation different from DVT documentation?

DVT proves the design meets requirements; PVT proves the product can be built repeatedly with controlled processes, stable yield, and standardized quality decisions using production-intent setups.

Do we need final work instructions at PVT or can they stay "draft"?

For a true production-intent PVT, work instructions should be close to final, because operator execution and control limits are part of what you’re validating.

What data should be included to demonstrate stable yield?

Yield by station and overall yield trends across builds, defect Pareto charts, rework rates, and evidence that corrective actions reduced recurrence.

How strict should change control be during PVT?

Very strict—changes should be reviewed and approved, and the ramp window should have a clear freeze rule so results remain comparable and root causes remain traceable.

What’s the most common reason PVT ramps fail?

Ambiguity—unclear configuration, unclear inspection criteria, or operator-dependent decisions that create variation and hide drift until late.

How do we handle cosmetic issues consistently in PVT?

Define a defect taxonomy and acceptance standards with representative samples, then standardize disposition rules (rework, scrap, use-as-is) and record outcomes with traceability.

Conclusion

PVT deliverables are the controlled release package that proves manufacturability: the configuration is locked, the production-intent process is repeatable, and quality decisions are standardized with stable yield evidence. Delivering finalized work instructions, inspection and test plans, defect and disposition rules, and data-backed ramp results—under strict change control—supports confident go/no-go decisions and reduces ramp surprises. For LCD display module integration, this discipline helps keep optical appearance and performance consistent as volumes scale.

MEIDAYINGNUO provides PVT documentation and manufacturing readiness support for LCD display module projects, including configuration control frameworks, process documentation, inspection and test definition, defect standards, and structured go/no-go release package organization to support controlled production ramps.

✉️ info@lcdmodulepro.com

🌐 https://lcdmodulepro.com/

-

Understanding PVT packages can enhance your knowledge of quality control in manufacturing, ensuring better product consistency. ↩

-

Exploring Production Control System Validation helps in grasping how to maintain quality and consistency in production processes. ↩

-

Understanding configuration control at PVT is crucial for ensuring product integrity and traceability in production. ↩

-

Exploring acceptance criteria will help you establish clear standards for quality and compliance in your processes. ↩

-

Understanding PVT documentation can enhance your quality management practices by reducing subjectivity in decision-making. ↩

-

Exploring this framework helps in grasping essential quality assurance processes that enhance product reliability. ↩