Active area defines the actual pixel boundaries that users see, making it the critical reference datum for window alignment rather than mechanical outline dimensions.

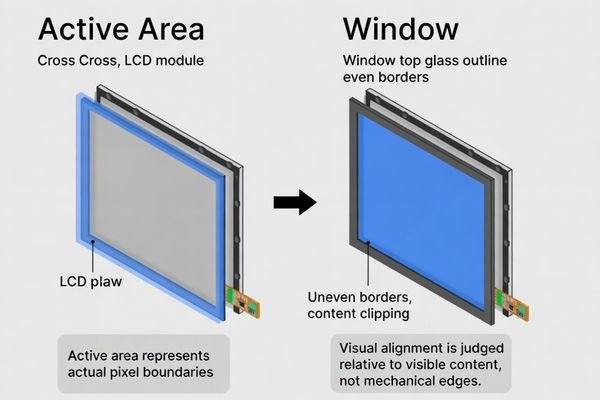

Active area is the LCD’s true pixel boundary, not the outer glass or frame. Because modules include non-display regions (mask, routing, margins), glass size and pixel area often differ. Window alignment is judged by what’s visible, so referencing the outline instead of the pixel boundary can create uneven borders, clipped content, or an off-center look even if mechanics are in spec.

In LCD display module integration, many “window misalignment1” complaints trace back to one simple mistake: centering to the mechanical outline instead of the pixel boundary. The outline is a mechanical reference for fit, mounting, and clearances, but the user evaluates symmetry relative to what they can see through the window. If the active area is offset from the outline—or if assembly introduces small rotation—your borders can look uneven or your content can appear cropped. Treat active area as the optical truth, then design margins and tolerances to keep the visible result consistent in production.

What is "active area" in an LCD display module?

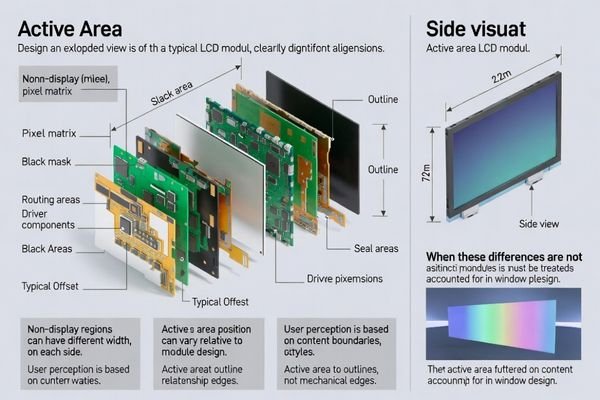

Active area represents the actual pixel-emitting region of the LCD panel, distinct from mechanical outline dimensions and non-display border areas.

Active area is the pixel-emitting region defined by the pixel array boundary, not the glass outline, bezel, or frame. LCD modules also include non-display zones like black mask borders, routing/driver areas, and mechanical margins, so outline and pixel area rarely match. Since the window reveals the pixel boundary, AA is the correct optical reference for alignment and cosmetics.

In practice, the relationship between active area and outline can vary by module design, optical masking style, and driver/routing layout. Some modules have centered active area2; others have a built-in offset that is normal and intentional. That is why “center the window to the module outline” is not a safe rule: it assumes the outline and pixel boundary share the same center. Correct window alignment starts with confirming the pixel boundary location, then referencing all visible cosmetics to that boundary rather than to the overall glass.

Physical Boundaries and Non-Display Regions

Active area is defined by where pixels exist and can be driven, while the surrounding regions may include black masks, seal/edge margins, routing space, and driver integration areas. These non-display zones are mechanically real but visually “dead,” and their widths can differ by side. If your product window reveals more of this region on one edge than the other, the display can look off-center even when the module is mounted correctly. Treat these regions as part of your masking strategy, not as alignment targets.

Visual Reference for User Experience

From a user standpoint, alignment is judged against the content boundary: where the image starts and stops. That boundary is the active area, not the outside of the glass. Even small positional errors can be obvious when borders are intended to look symmetric, especially with dark UI backgrounds or thin bezels. To protect user experience, define window size and placement relative to the pixel boundary and include both content-safe margins (to avoid clipping) and cosmetic margins (to hide normal variation).

Why does active area decide whether your window aligns?

Window alignment perception depends on the relationship between window edges and visible pixel boundaries rather than mechanical outline positioning.

Window alignment is judged against the pixel boundary users see, not the module outline. If the window references the wrong datum, small offsets can create uneven border reveal—more mask on one side and possible content clipping on the other. The same tolerance stack may look fine when referenced to AA but look wrong when referenced to outer glass, so tolerances should anchor to AA position variation.

Human perception is highly sensitive to symmetry. A 0.3–0.5 mm difference in border reveal can be noticed quickly, especially when corner radii, chamfers, and ink masks create clear visual cues. Active area is the “truth” the eye uses to judge alignment, so any datum strategy that ignores the pixel boundary risks cosmetic failures that can’t be argued away with mechanical compliance. If the goal is a clean, centered look, you must manage active-area position, not just the outline.

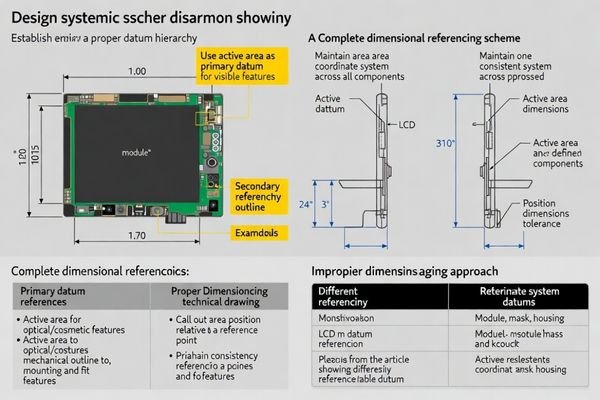

What dimensions should you reference to avoid AA vs outline confusion?

Proper dimensional referencing requires treating active area as the primary optical datum while using mechanical outline as secondary datum for mounting and fit.

Use active area as the primary datum for user-visible features, and use outline as a secondary datum for fit and mounting. Drawings should call out AA width/height, AA X/Y location from a defined reference, and AA position tolerance. Define window cutout and mask to the same datum scheme with clearances for mask and assembly. For complex stacks, enforce one shared coordinate system across suppliers.

A good rule is: if the user can see it, reference it to active area; if it must fit or mount, reference it to outline and mounting features. Problems occur when teams mix these purposes in one dimension chain, or when different vendors use different coordinate origins while sharing “the same” numbers. To keep everyone aligned, define a single datum hierarchy3 and coordinate system, then express window, mask, and module references in that same framework. This reduces interpretation gaps and makes tolerance stack-ups analyzable.

| Reference Datum | Primary Application | Key Specifications | Tolerance Considerations |

|---|---|---|---|

| Active Area | Window sizing and positioning | Pixel boundary dimensions and location | Visual symmetry and content safety margins |

| Mechanical Outline | Mounting and fit constraints | Overall glass size and mounting holes | Assembly clearances and mechanical interfaces |

| Cosmetic Borders | Visual appearance management | Mask width and corner treatments | Aesthetic balance and manufacturing variation |

| Assembly Features | Integration and serviceability | Locating pins and retention features | Alignment repeatability and service access |

Systematic datum definition ensures that optical requirements and mechanical constraints are managed independently while maintaining proper coordination for successful integration outcomes.

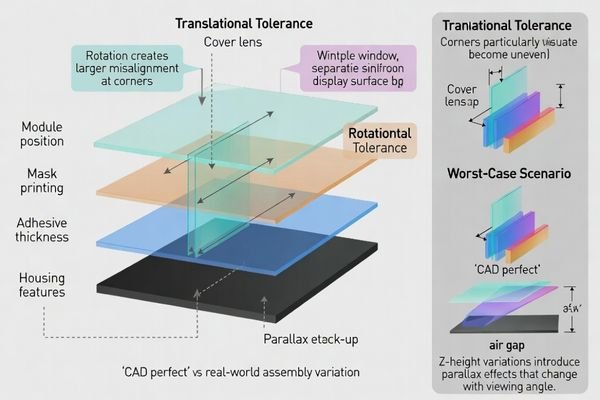

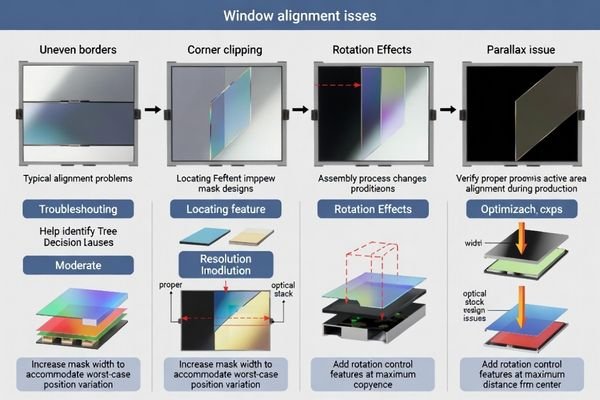

How do tolerance stack-ups and assembly features shift the visible window?

Manufacturing and assembly variations can shift the apparent window position even when active area is properly defined and controlled.

Even with AA defined, visible alignment can drift from tolerance stack-ups across the module, cover-lens printing, brackets, adhesives, and assembly repeatability. Borders and corner features amplify perceived asymmetry. Rotation is especially risky because small skew becomes obvious at corners, and z-height variation can add parallax. Budget both translation and rotation, control locating features, and validate with representative builds—not only nominal CAD overlays.

Tolerance stack-up is where “looks perfect in CAD” becomes “looks off in real life.” A window can be correctly sized yet still look wrong if the assembly introduces slight rotation or if the cover lens mask shifts relative to the active area. Z-height also matters: when the window is separated from the pixel plane by a cover lens and air gap, parallax can make borders appear different from different viewing angles. The safest approach is to model worst-case translation and rotation, then validate with real parts and real processes—especially adhesives, gaskets, and compression that can drift during cure.

I’ve observed that tolerance accumulation affects visual alignment more dramatically than individual component specifications suggest because human perception is sensitive to asymmetry and rotation, requiring comprehensive stack-up analysis and assembly control to maintain consistent appearance across production variation. For complex window alignment challenges requiring systematic tolerance analysis4 and assembly control during LCD module integration projects demanding precise optical positioning and cosmetic appearance management, engineering teams can contact info@lcdmodulepro.com when alignment stability requires specialized expertise in optical stack design and manufacturing variation control.

Translation and Rotation Effects

Small translational offsets create uneven border reveal, but rotation is often more damaging because the error increases toward the corners. A tiny angular skew can make one corner look clipped while the opposite corner shows extra mask, even if the center looks acceptable. This is why alignment strategies should specify both positional and rotational limits, not just X/Y offsets. Locating features, datum surfaces, and assembly sequence should be designed to resist rotation during placement and cure.

Assembly Process Variation

Adhesive thickness, gasket compression, and curing conditions can change where parts “settle,” creating drift after initial placement. Thermal expansion and repeated handling can also shift alignment if constraints are not balanced. To reduce these risks, control the assembly sequence, apply consistent compression, and design locating features that constrain movement without introducing stress. Inspection should check the active area position relative to the same product datums used in production, not just to standalone module dimensions.

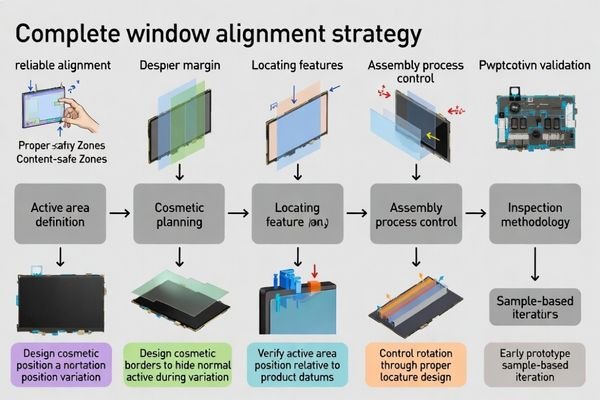

How do you design a reliable window-alignment strategy for custom LCD modules?

Reliable window alignment requires systematic design approach anchoring all cosmetic features to active area while controlling manufacturing and assembly variables.

Start by treating AA as the optical truth: design window borders and ink masks to hide normal AA position variation while protecting content-safe margins. Use one datum scheme, define acceptable offsets in visible terms (symmetry, corner clearance, content margin), and translate them into controls: locating features to limit rotation, controlled adhesive/gasket compression, and inspection that verifies AA position relative to product datums. Prototype early to tune borders before tooling.

A reliable alignment plan is a closed loop: define optical targets5 around the pixel boundary, design cosmetics to tolerate normal variation, and enforce repeatable assembly controls so production matches the intent. Start with the “visual contract” (how much border symmetry is acceptable, where content must never be clipped), then choose mask widths and window clearances that can realistically cover worst-case stack-ups. Finally, lock the process: use rotation-resistant locating features, stable bonding/compression, and an inspection method that measures the right thing—the active area relative to the product window references.

Design Foundation and Datum Strategy

Optical Truth Reference:

Establish active area as the primary optical reference for all user-visible features, using one coordinate system that stays consistent across the module, mask, window, and housing.

Cosmetic Margin Planning:

Design window borders, ink masks, and corner treatments with enough margin to hide normal AA position variation while protecting content-safe areas under worst-case tolerance.

Locating Feature Design:

Add locating features that control both translation and rotation during assembly so the module cannot “float” into a skewed position as adhesives cure.

Manufacturing Control and Validation

Assembly Process Control:

Control the assembly sequence, adhesive application, and compression conditions to minimize drift and maintain repeatable placement from prototype through production.

Inspection Methodology:

Inspect active area position relative to the product’s true assembly datums (not just module outline), so acceptance criteria correlate with what users will see.

Sample-Based Iteration:

Use early prototypes with representative parts and process variation to refine border widths, radii, and tolerances before committing to tooling.

Supply Chain Continuity:

Plan for component lifecycle and supplier variation so cosmetic alignment remains stable even when materials or subcomponents change within qualified limits.

FAQ

Is active area the same as "viewing area"?

Not always. Active area is the pixel array boundary, while viewing area can include what’s visible through masks or cover optics; the best reference for window alignment is still the pixel boundary plus defined cosmetic margins.

Why does my window look off-center even if the CAD is centered?

CAD often centers to the outline, but the active area can be offset relative to the outline, and assembly tolerances or slight rotation can make the visible border uneven.

How much border should I leave around the active area?

It depends on tolerance stack-up, mask/ink design, and viewing distance; define a content-safe margin and a cosmetic margin that can hide normal positional variation.

Can rotation cause more trouble than translation?

Yes. A small angular skew can create large corner misalignment, so locating features and assembly sequence should control rotation tightly.

What should I include in drawings to avoid supplier interpretation gaps?

Call out active area size and position with tolerances, define datums clearly, and ensure the window, mask, and mechanical features all reference the same coordinate system.

When is customization necessary for perfect window alignment?

When the enclosure window shape, corner radii, or cosmetic border constraints leave little tolerance, customization helps align active area, mask design, and mounting features to the product’s optical goals.

Conclusion

Active area represents the true pixel boundary that determines user-visible alignment quality, making it the essential reference datum for window positioning rather than mechanical outline dimensions. Effective window alignment requires systematic approach treating active area as the optical truth while managing tolerance stack-ups, assembly variation, and manufacturing constraints through proper datum hierarchy and control methodology. By anchoring cosmetics to pixel boundaries, budgeting translation and rotation, and validating early with representative builds, teams can achieve consistent window alignment across production.

MEIDAYINGNUO provides comprehensive window alignment and optical integration services for custom LCD module applications requiring precise active area management and systematic alignment control, including datum strategy development, tolerance analysis, assembly process optimization, and prototype validation for complex display integration projects demanding consistent visual appearance and manufacturing feasibility. Contact our optical integration specialists when window alignment challenges require systematic design methodology and expert manufacturing control support.

✉️ info@lcdmodulepro.com

🌐 https://lcdmodulepro.com/

-

Understanding the causes of window misalignment can help you avoid common pitfalls in LCD integration. ↩

-

Understanding the active area is crucial for optimizing display performance and ensuring accurate visual alignment. ↩

-

Understanding datum hierarchy is crucial for effective design and integration in engineering projects. ↩

-

Exploring systematic tolerance analysis can enhance your knowledge of maintaining quality and precision in manufacturing processes. ↩

-

Understanding optical targets is crucial for ensuring precision in alignment plans, enhancing overall product quality. ↩