Custom LCD module projects require NRE investment to transform concepts into producible designs while managing project-specific risks and ensuring long-term consistency.

NRE (Non-Recurring Engineering) is a one-time engineering investment that turns custom LCD display module requirements into a production-ready release. It covers upfront definition, feasibility confirmation, prototyping, validation, and production documentation—work that must happen before stable manufacturing is possible, regardless of volume. When scoped to clear deliverables, NRE reduces integration surprises, protects schedule predictability, and improves batch-to-batch consistency over the product lifecycle.

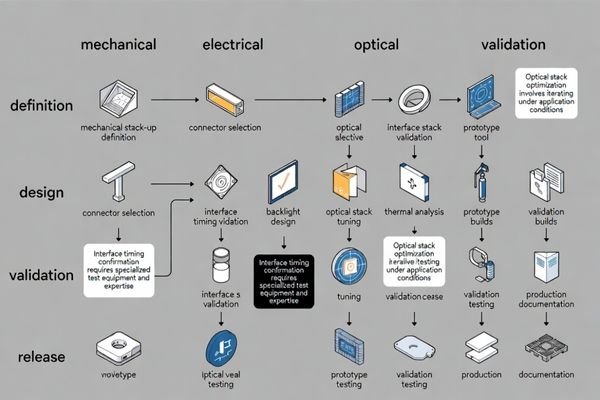

In LCD display module integration, teams often underestimate NRE1 because they focus on visible changes (outline, brightness, connector) while overlooking the work that makes a custom design repeatable in production. A small requirement change can trigger new timing confirmation, optical decisions, mechanical stack-up reviews, and validation steps that must be completed before a reliable production ramp. NRE exists to fund that upfront effort early—so gaps are closed during development, not discovered during manufacturing or field deployment.

What does NRE mean in a custom LCD display module project?

NRE represents the one-time engineering investment required to develop custom LCD modules from initial concept to production-ready implementation.

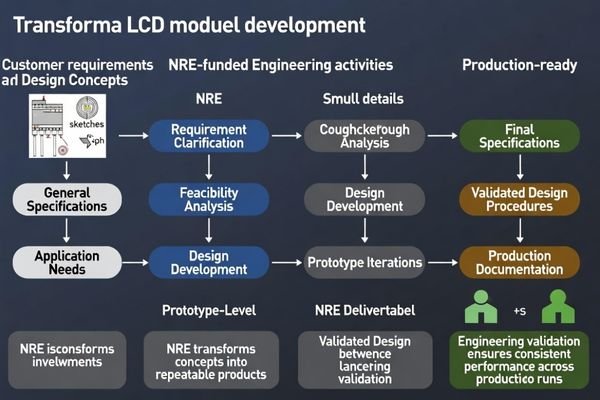

NRE (Non-Recurring Engineering) is the one-time engineering and setup cost required to transform custom LCD display module concepts into producible, verifiable, and repeatable products, covering upfront work including requirement clarification, feasibility analysis, electrical and mechanical design, optical and backlight decisions, interface timing alignment, prototype builds, validation planning, and production documentation regardless of volume because customization introduces project-specific development effort that cannot be amortized without dedicated funding.

From an engineering standpoint, NRE is not “a fee for drawings”—it is the cost of making the design manufacturable and predictable. Unit price mainly reflects recurring manufacturing and material costs, while NRE covers work that must be done once to remove uncertainty before production. Tooling may be included when needed, but NRE also covers the engineering time2, prototype cycles, and validation required to confirm the module will meet requirements in the real system. This is why NRE is common even when the custom module looks similar to something that already exists.

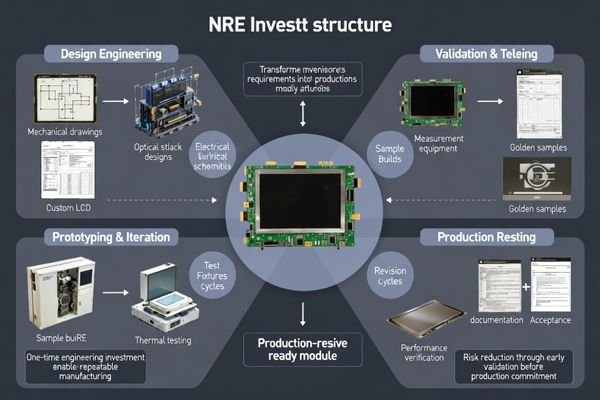

Development Investment Structure

NRE pays for one-time tasks that enable a production release: turning requirements into controlled specifications, confirming feasibility, and converging on a stable implementation. It typically includes reviews and decisions that lock mechanical stack-up, interface definition, power/backlight strategy, and optical approach. It also covers prototype builds and the work to interpret results into design changes. The output should be a release package that manufacturing can repeat—not a collection of partial drafts.

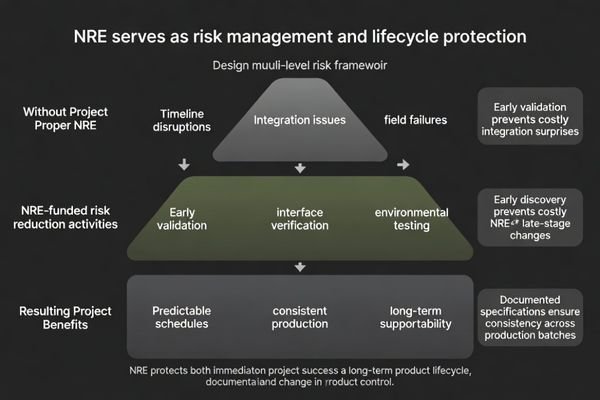

Risk Management Framework

Custom module development contains unknowns that must be proven, not assumed—fit, timing compatibility, thermal margins, and visibility behavior in the target environment. NRE funds early experiments and validation so risks are discovered while changes are still low-cost. It also supports defining acceptance criteria and test methods, so pass/fail is objective rather than subjective. When risks are handled early, the production ramp becomes smoother and less disruptive.

Which engineering activities does NRE typically pay for?

NRE funds comprehensive engineering activities transforming requirements into validated production-ready implementations.

NRE commonly funds engineering tasks transforming requirements into implementation details including drawing reviews and mechanical stack-up definition, connector and pinout alignment, interface timing confirmation, power and backlight driver strategy, optical stack selection covering cover lens and viewing angle considerations, early risk analysis for EMI, ESD, thermal limits, and reliability targets plus prototype-related work including BOM finalization, sample build coordination, test fixture preparation, and iterative debug cycles achieving stable performance.

Even “minor” customization can create new verification work. A small outline change can affect mounting stress and uniformity; a brightness target change can alter thermal behavior and lifetime assumptions; an interface constraint can require timing alignment and signal checks. NRE typically pays for the engineering steps that connect these changes to measurable outcomes: updated drawings and stack-ups, confirmed electrical behavior, prototypes that exercise the real constraints, and a validation plan3 that demonstrates repeatability. When these activities are skipped, the project often pays later through rework, unstable yields, or field issues.

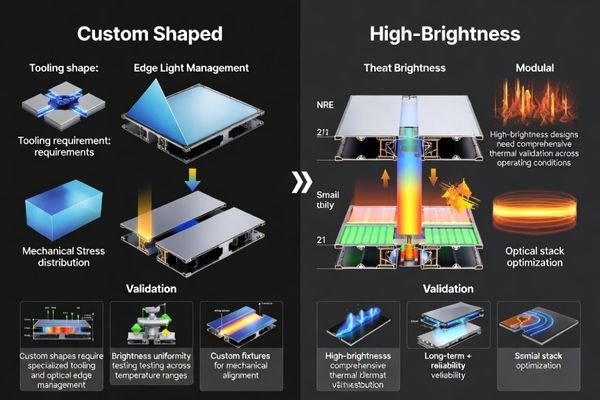

How do tooling, samples, and validation drive NRE in custom-shaped or high-brightness modules?

Custom-shaped and high-brightness modules require additional NRE investment for specialized tooling, validation protocols, and iterative optimization.

Custom-shaped modules and high-brightness designs require additional upfront investment because they depend on optical and mechanical details that cannot be proven by calculation alone, with new outlines, cover lenses, or mounting features potentially requiring dedicated tooling, fixtures, or alignment processes while high-brightness targets raise thermal and uniformity risks requiring validation with controlled test conditions and time/temperature sweeps, plus prototype iterations addressing light guide alignment, diffuser stack, and mechanical compression effects on uniformity, glare performance, and long-term stability.

Tooling and fixtures may be necessary to build or align parts consistently, but the bigger NRE driver is often validation depth. High-brightness targets can expose thermal gradients and uniformity drift that only appear after warm-up, and custom shapes4 can introduce optical edge effects or mechanical pressure sensitivity that require iteration. Because these effects are highly dependent on stack-up and assembly conditions, samples and measurements are usually required to converge the design. NRE funds the prototype-and-verify loop so the final build remains consistent across batches instead of relying on “best-case” early samples.

| Customization Type | NRE Drivers | Validation Requirements |

|---|---|---|

| Custom Shapes | New tooling and fixtures | Mechanical fit and optical alignment verification |

| High-Brightness | Thermal and uniformity analysis | Time/temperature stability and brightness consistency |

| Optical Treatments | Cover lens and surface optimization | Glare control and viewing angle validation |

| Interface Changes | Timing and signal integrity | Compatibility and EMI performance confirmation |

NRE investment in specialized validation helps ensure custom modules achieve consistent performance across production batches rather than discovering optimization requirements during volume manufacturing.

Why is NRE also about project risk, schedule, and lifecycle—not just "design work"?

NRE functions as structured investment reducing integration uncertainties and ensuring predictable project outcomes beyond basic design activities.

In custom module projects, uncertainty costs often exceed component costs, making NRE a structured investment reducing integration surprises through early discovery of interface compatibility, mechanical fit, thermal margins, and reliability assumptions preventing project delays from late rework or field failures. NRE also supports process definition and documentation protecting lifecycle continuity through controlled specifications, acceptance criteria, golden samples, and change control practices maintaining future build consistency even as components evolve.

NRE reduces schedule risk by moving unknowns to the front of the project, where fixes are cheaper and faster. When timing, mechanical fit, or thermal margins are not confirmed early, late-stage changes can ripple into tooling, layout, or enclosure redesign, extending lead times and increasing cost. Lifecycle risks also matter: a custom module is rarely a one-time shipment, so controlled specifications and acceptance criteria protect consistency as materials and components evolve. For strategic NRE planning and risk management guidance during complex custom module projects requiring comprehensive development support, engineering teams can contact info@lcdmodulepro.com when systematic project planning requires expert analysis of technical uncertainties and development scope optimization.

Schedule Predictability

NRE enables a milestone-driven plan: requirements freeze, prototype builds, validation gates, and production release. This structure prevents “endless iteration” by tying each cycle to specific questions that must be answered (fit, timing, thermal, visibility). It also reduces risk from late requirement drift by clarifying what is included in the current scope. When deliverables are explicit, schedule discussions become measurable rather than subjective.

Lifecycle Protection

A production-ready custom module needs more than a working sample—it needs repeatable controls. NRE supports golden samples, acceptance criteria, and documented test methods that keep future builds aligned. It also enables change-control practices so updates do not silently alter optics, performance, or fit. These lifecycle controls5 reduce the chance of mid-life redesigns and protect serviceability over multi-year deployments.

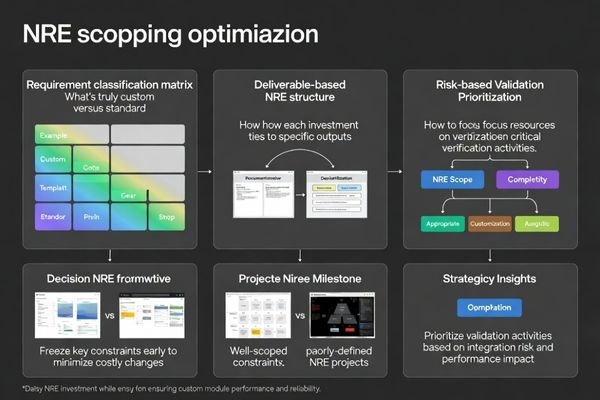

How can you scope NRE smartly to control cost while protecting performance?

Effective NRE scoping requires separating new development from reusable elements while tying investment to measurable deliverables.

Smart NRE scoping starts with separating truly new requirements from reusable elements, then tying each NRE item to measurable deliverables including defined requirements and drawings, interface timing confirmation, prototype sample plans, validation matrices, and production release documentation. Cost control requires clarity through early constraint definition covering outline, mounting, brightness targets, viewing angles, interface specifications, and environmental limits with agreed acceptance criteria preventing repeated payment for changing project goals.

The best way to control NRE is to reduce churn6: freeze the constraints that drive the most rework (outline, mounting stack-up, interface, brightness targets, viewing angles, and environment) and align on acceptance criteria early. Then scope NRE around concrete deliverables so progress is visible: a controlled spec pack, a prototype plan with pass/fail metrics, validation results that close key risks, and a production release package. If timelines are tight, prioritize work that de-risks integration first—mechanical fit, power/backlight stability, and visibility under real lighting—then deepen validation where risk remains. This approach keeps cost focused on preventing the failures that are most expensive later.

Custom Module NRE Optimization Framework:

- Requirement Clarity and Constraint Definition: Freeze outline and mounting stack-up early, define brightness/viewing targets with a measurement recipe, lock interface timing and power constraints, and set environmental/reliability assumptions with clear pass criteria

- Engineering Scope Optimization: Reuse proven architectures where possible, focus new work on the changed elements, and plan prototype iterations around specific questions (fit, uniformity, thermal, timing) rather than open-ended tuning

- Risk-Based Investment Prioritization: Validate mechanical fit and thermal headroom first, confirm optics/visibility under realistic conditions early, and verify interface compatibility and EMI sensitivity before final release decisions

- Deliverable Definition and Change Control: Produce a production release package (specs, drawings, test method, acceptance criteria), define golden sample usage, and establish change control expectations to protect batch consistency and lifecycle continuity

FAQ

Is NRE always required, even if my module is "almost standard"?

Often yes, because any change that affects outline, optics, interface timing, or mounting typically requires engineering confirmation and validation to ensure production repeatability.

Can NRE be reduced by reusing existing designs?

Yes—reusing proven architectures can reduce design and validation scope, but the remaining NRE should still cover project-specific integration checks and documentation.

Is NRE the same as tooling cost?

Not exactly; tooling can be part of NRE, but NRE also includes engineering time, prototyping, testing, fixtures, and the work to reach a production-ready release.

When should NRE be paid in a custom module project?

Typically when the project scope is agreed and engineering work begins, because it funds the upfront activities needed before samples and validation can proceed.

What deliverables should I expect in exchange for NRE?

Clear specifications, drawings, interface/timing definition, prototype plan and results, validation criteria, and production release documentation with change control expectations.

How does NRE help avoid future redesign costs?

By validating risks early and locking controlled specifications and acceptance criteria, NRE reduces late-stage rework and protects batch consistency and lifecycle continuity.

Conclusion

NRE exists in custom LCD display module projects because the upfront engineering work to define, de-risk, prototype, validate, and document a project-specific design represents real development effort that must be completed before stable production becomes possible. When scoped with clear deliverables and frozen constraints, NRE functions as a practical investment that turns uncertainty into predictable performance, schedule adherence, and long-term supportability—not simply payment for drawings. Effective NRE management treats development as structured risk reduction so the module can be produced consistently throughout its lifecycle.

MEIDAYINGNUO provides comprehensive NRE planning and custom module development services supporting complex industrial, dashboard, and specialized display applications requiring optimized engineering investment and systematic development processes. Our engineering team offers structured NRE scoping including requirement analysis, risk assessment, prototype planning, validation strategy development, and production readiness verification ensuring custom module projects achieve performance targets while controlling development costs and maintaining predictable schedules throughout complex customization development cycles. Contact our technical specialists when custom module projects require expert development planning and systematic engineering investment optimization for successful long-term deployment.

✉️ info@lcdmodulepro.com

🌐 https://lcdmodulepro.com/

-

Understanding NRE is crucial for managing costs and ensuring smooth production processes in custom designs. ↩

-

Exploring the role of engineering time can provide insights into project efficiency and cost management. ↩

-

A solid validation plan is essential for project success, ensuring repeatability and reliability in outcomes. ↩

-

Exploring the impact of custom shapes can provide insights into design challenges and solutions in manufacturing. ↩

-

Exploring lifecycle controls can provide insights into maintaining product quality and consistency over time. ↩

-

Reducing churn is key to improving efficiency and cost-effectiveness in product development, and this link will provide actionable strategies. ↩