Industrial integrators often purchase incomplete LCD components that later create costly interface mismatches, supply inconsistencies, and field failures.

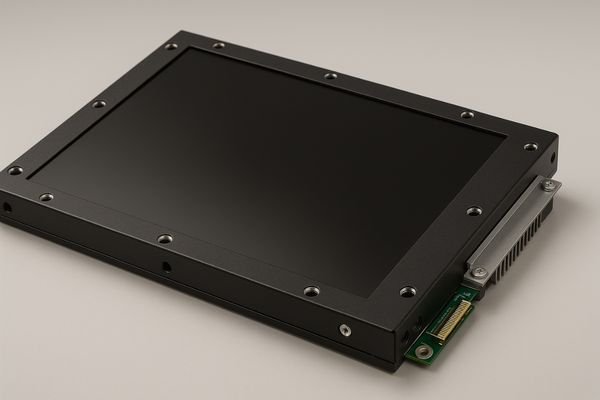

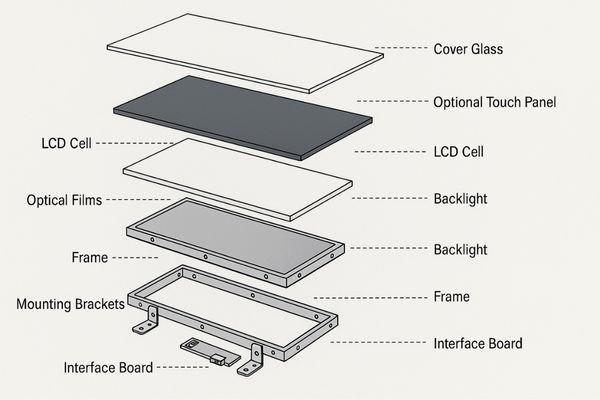

An lcd module is a complete display subassembly built around an LCD panel with backlight, connectors, mounting features, and optionally touch/cover glass—designed for direct system integration with clear responsibility boundaries for mechanics, power, signal, and reliability validation.

Why system boundaries matter

From an engineering standpoint, I usually evaluate lcd modules based on how cleanly they divide responsibility between the display supplier and the system integrator. A proper module definition establishes where your system design starts—and where supplier accountability ends.

| Integration Boundary | Minimum Module Includes | Extended Module May Add | Risk if Undefined |

|---|---|---|---|

| Mechanical | Mounting features, bezel/frame | Cover glass, optical bonding | Assembly stress, light leak |

| Electrical | Display interface, backlight power | Touch controller, cables/harness | Signal integrity, EMI problems |

| Optical | Backlight, basic polarizer | Anti-glare, enhanced films | Readability issues in field |

| Reliability | Defined temperature range | Extended testing, certifications | Early failures, inconsistent lots |

What Is an lcd module, and what’s included in the delivery?

Incomplete display procurement often leads to mismatch between prototypes and mass production.

An lcd module includes the LCD cell, backlight assembly, control electronics, mounting features, interface connections, and optionally touch/cover glass—delivered as a system-ready subassembly with clear integration boundaries.

In my lcd module integration work, I’ve found that clear delivery scope prevents most deployment problems. The core module includes the LCD cell (the actual display element), backlight assembly (LED strips or edge lighting with optical films), interface connections (FPC/connectors), and mounting structure (frame/brackets).

Based on the projects I support with OEMs and system integrators, extended modules often include additional integration-ready elements: touch sensors, cover glass/lens, optical bonding layers, complete cable harnesses, and sometimes backlight driving circuits. The critical distinction is whether you’re ordering a component for early prototyping or a production-ready module1 that can directly enter system design and mass-production onboarding. When this boundary is explicitly defined, you avoid late-stage surprises in interface compatibility, mechanical fit, EMC/ESD performance, and supply consistency.

Which specs define an LCD display MODULE for industrial reliability?

Surface specs like size and resolution are just the starting point; real reliability comes from constraints matched to your application.

For true industrial reliability, define brightness against ambient light, temperature range with derating, power sequencing with inrush control, and lifetime expectations under actual duty cycles.

When I review failed field installations, I often find that basic specs were prioritized while environmental and system constraints were undefined. Ambient light conditions determine your target brightness and anti-reflection strategy, which directly impact power consumption and thermal management requirements. Operating temperature range, vibration/shock tolerance, and duty cycles (hours-per-day, power cycles) determine backlight driving methods, derating curves, and realistic lifetime expectations.

System power design requires careful specification of input requirements, sequencing, and stability. In my engineering practice, I document these as hard constraints:

Temperature range: Both storage and operating, including any derating curves

Brightness: Target nits tied to the ambient light scenario, including any auto-dimming/derating strategy

Power: Input rails, sequencing, inrush current limits, sleep/standby modes

Mechanical: Mounting method, load distribution, tolerance stack-up

Lifetime: Hours at specified brightness/temperature with acceptable degradation

The real differentiator for industrial LCD display MODULEs2 is turning these application constraints into enforceable specifications with validation tests—while clearly stating boundaries and assumptions for the intended environment. Please contact us at info@lcdmodulepro.com for assistance developing application-specific constraints that support reliable deployment.

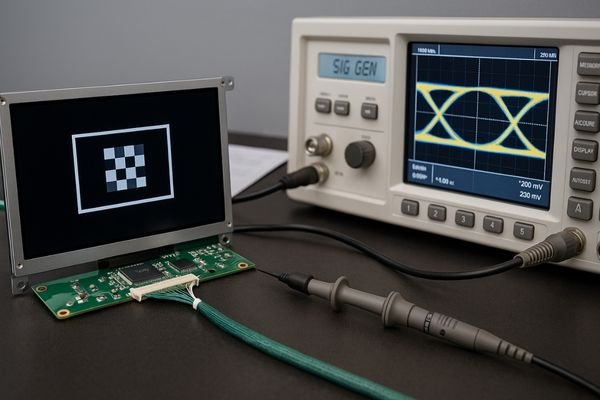

How do you choose LVDS or eDP without signal-integrity surprises?

Interface problems rarely present as simple "no display"—they manifest as inconsistent production quality and field reliability issues.

Start with bandwidth requirements and controller compatibility, then evaluate cable length, EMI exposure, and system grounding—validated with targeted signal integrity and EMC tests.

Interface selection approach

When evaluating interfaces for an lcd module, I first confirm bandwidth headroom based on resolution, color depth, and refresh rate. Then I assess the physical integration path—cable length, routing constraints near noise sources, shielding options, and system grounding strategy. To make the results transferable to production, I validate under worst-case conditions (maximum harness length, the noisiest routing locations, and temperature drift at operating extremes).

Practical comparison and integration rules

LVDS (Low-Voltage Differential Signaling):

- Mature, widely supported in embedded controllers

- Cost-effective for medium resolutions

- More sensitive to cable quality and length

- Requires disciplined routing and grounding

- Limited bandwidth for very high resolutions

eDP (Embedded DisplayPort3):

- Higher bandwidth supports higher resolutions

- Can be more tolerant in noisy systems when the link budget, routing, and grounding are executed well

- Requires compatible controllers and correct timing/configuration

- Packet-based protocol adds flexibility

- Debugging can be more process-dependent when issues occur

In practice, the most reliable approach is to turn interface selection into system integration rules that engineering and manufacturing can repeatedly execute: define connector retention and strain relief, control impedance for high-speed pairs, place ESD protection deliberately, lock power sequencing for panel/backlight, manage common-mode noise paths, and verify with ESD, EMI, and temperature cycling on representative builds.

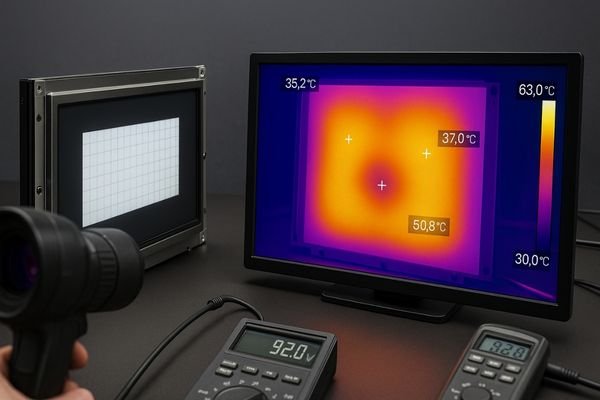

What mechanical, thermal, and validation steps prevent mass-production failures?

Prototype success doesn’t guarantee production stability—most large-scale failures originate in mechanical stress and heat management.

Design controlled load paths in mounting, create defined thermal pathways for backlight heat, and implement progressive validation from prototype to production with clear pass/fail criteria.

Mechanical and thermal design discipline

In my lcd module integration work, I focus on creating controlled load paths in the mounting system. Whether using bezel clamping, standoffs, or support frames, the design must distribute forces evenly to avoid stress concentration that can cause light leakage or panel cracking. The tolerance stack-up analysis ensures that normal manufacturing variation won’t create interference or uneven pressure points.

High brightness displays in long-duty applications create significant heat, particularly from LED backlights. From an engineering standpoint, I treat thermal planning as a closed loop: establish a defined conduction path from the backlight region to the chassis or heat-spreading structure, place measurable temperature points, set limits tied to reliability goals, and implement thermal throttling/dimming strategies that protect the module under worst-case ambient and system heat loading.

Progressive validation and change control

When I review failed field installations, I often find that validation was compressed or skipped. Effective validation follows a progressive approach—prototype validation for core function, design validation for environmental limits and accelerated aging, and production validation for statistical sampling and lot consistency. Critical tests include thermal cycling, burn-in, vibration/shock, ESD/EMC, and incoming consistency checks, each with quantified pass/fail criteria.

Equally important is change control for panel revisions and alternates. If the panel or key optical/backlight items change, the integration boundary and the validation impact must be assessed before shipment, otherwise the same part number can behave like multiple products across different production lots.

MEIDAYINGNOU lcd module recommendations for bar, square, and outdoor projects

When selecting a display module for industrial and commercial applications, the key is matching form factor, interface robustness, and environmental protection to your specific integration scenario. MEIDAYINGNOU specializes in non-standard display solutions where mechanical fit, interface stability, and environmental performance must work together as a system—particularly for bar-type, square/round, and high-brightness outdoor applications.

| Application / Scenario | Usage Pattern | Display Requirements | Recommended Model | Key Integration Considerations |

|---|---|---|---|---|

| Shelf-edge signage, vehicle info displays | Information-dense content in narrow spaces | Compact ultra-wide format, clean text, moderate brightness | BU156X | Cable routing in tight spaces; validate power stability for long duty cycles; mounting that prevents stress |

| Control rooms, production displays | Wide information bands, alarm status | Large ultra-wide format, consistent color, multi-zone content | BU320S | Thermal planning for continuous operation; signal margin over longer cables; stable mounting for large format |

| Industrial HMI, machine controls | Operator interfaces, equipment status | Square format with balanced layout, touch compatibility | SQ220S | EMI planning in machinery environments; robust mounting for vibration; operator viewing angle validation |

| Outdoor kiosks, transit info | Sunlight-readable content | High brightness, thermal management, weatherproofing | HB215X | Heat dissipation at peak brightness; power stability across conditions; condensation-aware protection design |

| Custom equipment integration | Brand-specific UI, space-constrained designs | Customized outline, optimized interface | Custom-Shaped LCD Display Module | Early mechanical definition; interface compatibility testing; progressive validation plan |

Based on the projects I support with OEMs and system integrators, this approach aligns the lcd module selection with both immediate implementation needs and long-term support requirements. The key is working backward from the application scenario to define mechanical boundaries first, then selecting the interface strategy and environmental protection features that support reliable field performance and consistent supply.

FAQ

1. What’s the difference between an LCD panel, an lcd module, and a full display unit?

A panel is the core display component; a module adds integration-ready boundaries (connectors, mounting, backlight, optional extensions); a full display unit typically includes housing, power, and system-level control. Define where your system responsibility starts and ends before selecting.

2. How do I choose the right interface (LVDS, eDP, or others) for my controller?

Start with bandwidth and controller capability from resolution/refresh rate, then evaluate cable length, EMI environment, connector choices, and power sequencing. The goal isn’t only "it lights up," but consistent mass production and robust field behavior.

3. How much brightness do I really need for indoor, semi-outdoor, or outdoor use?

Brightness must be defined together with ambient light, reflection control, and viewing distance. Higher brightness increases power and heat, so thermal design and dimming/derating strategy must be planned to avoid trading readability for reliability.

4. What mechanical mounting approach reduces light leakage and panel cracking?

Focus on load path and tolerance stack-up: distribute clamping/support forces, avoid stress concentration, and control bezel shading, assembly gaps, and torque quantitatively—then validate under thermal expansion and vibration conditions.

5. How can I manage long-term supply consistency and panel revisions?

Use a disciplined change-control flow: freeze critical parameters, define allowed alternates, set incoming inspection rules, enforce validation gates for substitutes, and integrate impact assessment into production onboarding.

Conclusion

Selecting the right lcd module for industrial and commercial projects requires converting your application scenario into clear requirements and validation steps. The process starts with defining the delivery boundary, then establishing hard constraints for brightness, temperature range, power design, and expected lifetime.

MEIDAYINGNOU specializes in turning challenging display requirements into reliable module solutions—whether you need ultra-wide bar displays, square/round/irregular formats, or outdoor high-brightness modules. For engineering support in defining your LCD display MODULE requirements and validation plan, the contact details are provided below.

✉️ info@lcdmodulepro.com

🌐 https://lcdmodulepro.com/

-

Understanding production-ready modules can streamline your design process and ensure compatibility, reducing deployment issues.. ↩

-

Exploring specifications for industrial LCD display MODULEs can enhance your knowledge of reliable and effective display solutions. ↩

-

Discover the advantages of eDP, including its high bandwidth and flexibility for advanced display solutions. ↩