Selecting the right display module for outdoor terminals and EV charging stations involves complex trade-offs between readability, durability, and system integration. A choice that looks good on paper can fail in real-world deployment if outdoor conditions aren’t properly considered.

Success in outdoor display integration requires addressing four interconnected challenges: the display must remain readable in direct sunlight, maintain reliability in harsh environments, achieve EMC compliance near high-power electronics, and support practical field service over a long deployment life.

In real EV charger and outdoor terminal deployments, display decisions quickly cascade into the door cutout, cover glass choice, sealing approach, cable routing, EMI/EMC risk1, cabinet heat management, and long-term serviceability. The display isn’t just showing information—it’s guiding users through payment and charging steps while exposed to sun, rain, temperature extremes, and electromagnetic interference from power electronics. The safest approach is early validation against real conditions, using representative samples of the mechanical stack and wiring environment—not just a lab bench setup.

How to Define Display Requirements for EV Charging Stations and Outdoor Terminals?

Before diving into specifications, you must document how your display will actually be deployed and used in the field.

The most successful outdoor display integrations start with mapping three critical aspects: the deployment scenario (fully exposed vs. sheltered, viewing patterns, interaction model), the environmental stresses (sunlight, temperature, moisture), and the service requirements (field replacement, remote monitoring, lifetime expectations).

Real-world success requires attention to both user needs and field constraints. Start by capturing measurable inputs such as: installation type (fully outdoor or sheltered), typical viewing distance and off-axis usage, touch vs. buttons, protective cover glass, target readability under worst-case lighting, cabinet worst-case internal temperature, cable length and routing path, EMC compliance expectations, operating hours per day, and acceptable end-of-life (EOL) brightness and color shift. If any of these items are unclear, the risk of late-stage redesign rises sharply—especially after the door design, sealing, and harness routing have been finalized.

Deployment Scenario Analysis

Your location and usage patterns drive many technical choices. Full outdoor exposure demands higher brightness direction, stronger reflection control, and tighter thermal margin, while semi-sheltered installations may reduce sunlight burden but still require glare control and reliable touch behavior. If the terminal sits behind glossy cover glass, validate readability on the real optical stack under harsh light (direct sun and strong reflections), because cover reflections and internal reflections often dominate what users actually see.

Service Life Planning

Define clear targets for operating hours, acceptable brightness decay, and field maintenance access. For long-deployed assets like chargers, “serviceability2” is an engineering requirement: connector reachability, harness strain relief, repeatable sealing after service, and a replacement process that can be done reliably in the field. If the site expects 24/7 availability, plan verification around real duty cycle and worst-case temperature—because thermal stress and continuous brightness are common drivers of early backlight degradation.

How to Choose the Right Size and Form Factor for Readability and Mechanical Integration?

Display size and format must balance clear user guidance with practical installation constraints.

The optimal size and form factor for outdoor terminals is determined by three key factors: the UI must support clear payment and status flows, touch targets must remain usable under glare and weather effects, and the mechanical design must enable reliable assembly and service access.

In outdoor terminals, practical integration often matters more than maximizing screen size. Choose size based on what improves task completion: readable text at standing distance, clear state transitions, and touch targets that remain usable when users are rushed, off-axis, or wearing gloves. If your UI is step-based (authorize → plug-in → charge → receipt), clarity is often better than density; if you show ads or multiple data panels, ensure the layout still keeps critical actions obvious under glare.

UI Flow Optimization

Focus on making critical information and touch targets3 clearly visible from typical user positions. Consider how sunlight and reflections will affect different screen areas throughout the day. A useful rule is: if direct sun or strong reflections are expected, keep primary action buttons and confirmation messages in areas less likely to be washed out by glare, and maintain strong contrast for pricing, status, and error prompts. If users may approach from the side, ensure the viewing behavior supports off-axis readability so the workflow remains obvious without requiring perfect alignment.

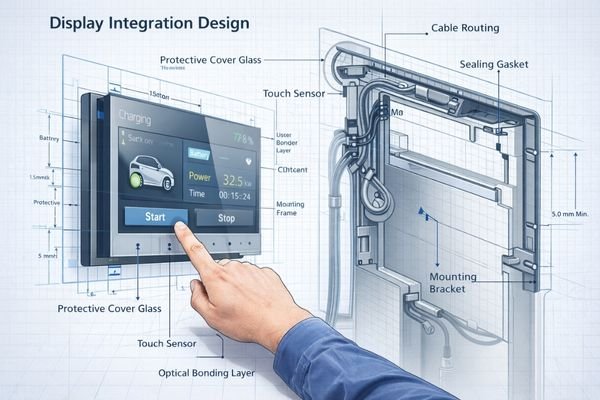

Mechanical Integration

The complete display stack including touch sensor, optical bonding, and protective cover must fit within your enclosure constraints while maintaining environmental seals and service access. Confirm active area alignment, bezel overlap, stack thickness, connector location, and cable bend radius early—then verify that sealing and mounting remain robust after repeated servicing. If cable runs are long or pass near noisy power sections, plan routing, grounding, and shielding from the mechanical design phase so the final assembly supports stable operation and EMC compliance.

How to Achieve Sunlight Readability and Low Reflection Outdoors?

Outdoor readability requires more than just high brightness—it demands a complete optical solution.

Successful outdoor display integration requires balancing three optical factors: the display’s native brightness must overcome ambient light, surface treatments must control reflections and glare, and the complete optical stack must minimize internal reflections that degrade contrast.

Consider these key factors for outdoor readability4:

- Direct sunlight vs. diffuse daylight requirements

- Specular and diffuse reflection control

- Optical bonding and air gap elimination

- Smart brightness control for day/night operation

- Power and thermal implications of high brightness

Each decision affects both readability and long-term reliability, making this a critical system-level choice. In practice, “brightness” alone often fails to fix outdoor complaints if glare and internal reflections dominate, so reflection control and stack validation can deliver larger perceived improvements than simply driving the backlight harder. If the terminal faces direct sun and uses cover glass, validate readability using a representative door/cover sample under worst-case lighting before freezing mechanical design; if the cabinet has limited cooling, validate the temperature rise at the brightness level required to stay readable.

How to Choose the Interface and System Architecture for EMC Compliance and Long-Cable Stability?

EMC compliance in EV charging stations requires careful attention to interface design and system architecture.

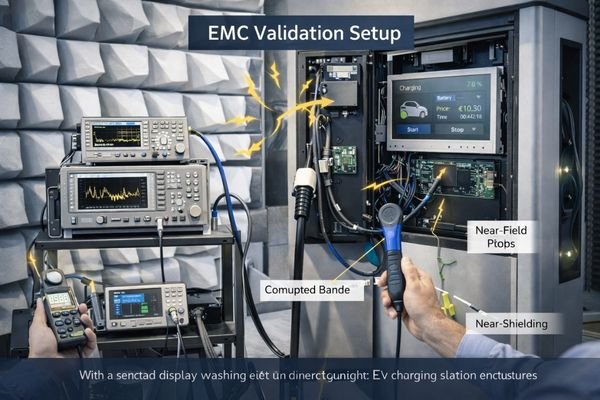

Display interface selection must consider three key factors: the electrical environment near high-power charging circuits, cable routing requirements for practical assembly, and long-term signal stability for reliable field operation.

Signal Integrity Design

EV chargers present unique EMI challenges. Interface selection must account for real noise conditions, grounding schemes, and cable routing constraints in your specific design. A practical flow is: start from what your platform natively supports, confirm bandwidth for your resolution/refresh targets, then evaluate margin using your real cable length, routing path, and grounding/shielding plan. If the harness is long, routed near power electronics, or must pass strict EMC testing, plan a system-level pre-validation with the actual enclosure and representative noise sources before committing to final harness and tooling.

System Architecture Planning

Consider using interface bridges or controllers to improve signal stability5 and serviceability, but carefully evaluate their impact on power, thermal, and reliability requirements. If a bridge improves robustness under long-cable or high-noise conditions, include it in the same trade study as thermal and service access—because added power and heat can affect backlight aging and enclosure temperature. The goal is not just to “make the screen work,” but to make it stable across production variation and field conditions.

Recommended MEIDAYINGNUO Models to Shortlist

Drawing from extensive experience with outdoor terminal manufacturers, we’ve identified display solutions that consistently meet demanding outdoor requirements.

Our engineering team specializes in helping customers validate complete display solutions against real-world deployment conditions.

| Application | Key Requirements | Environmental Demands | Recommended Model | Integration Notes |

|---|---|---|---|---|

| Primary Payment UI | High Brightness, Touch | Full Outdoor, EMC | HB238X | Thermal Design Critical |

| Main Display | Sunlight Readable | Semi-Sheltered | HB215X | EMI Shielding Needed |

| Status Display | Ultra-wide Format | Protected Location | BU215X | Cable Length Planning |

| Compact Terminal | Limited Space | High Brightness | HB185X | Mounting Optimization |

| Premium Charger | Large Format | Full Outdoor | HB270S | Complete Stack Design |

These models should be treated as a shortlist rather than a drop-in promise. Final selection should be confirmed against your real optical stack (touch/cover), cabinet thermal behavior at required brightness, harness length and routing, and EMC verification results. If any constraint is unusually strict—direct sun with strong cover glare, long cables near high-power sections, or 24/7 high brightness—early system-level validation is the fastest way to avoid late-stage redesigns.

FAQ

Do all outdoor terminals need maximum brightness displays?

Not always. The required brightness depends on installation location, viewing angle, and reflection control strategy. Semi-sheltered locations may work well with standard brightness if glare is properly managed.

What causes poor readability even with high brightness?

Often it’s reflection issues rather than insufficient brightness. Internal reflections between display layers and specular reflections from cover glass can significantly degrade contrast.

How do touch sensors perform in outdoor conditions?

Performance varies with environmental conditions. Water droplets, gloves, and temperature extremes can affect response. Proper integration and calibration are essential.

Why are EMC issues more common in EV chargers?

High-power charging circuits generate significant electromagnetic interference. Display signals must be properly protected through shielding, grounding, and careful cable routing.

What defines acceptable display lifetime for outdoor use?

Focus on measurable metrics: brightness decay over time, temperature cycles survived, and maintained readability under specified conditions rather than just hours of operation.

Conclusion

Successful outdoor display integration demands careful attention to readability, durability, and system integration. By validating your display solution against real deployment conditions early in development, you can avoid field issues and ensure reliable operation throughout your product’s service life.

MEIDAYINGNUO specializes in display solutions engineered for demanding outdoor applications. Our team can help validate your complete display integration strategy against real-world requirements. For detailed discussion of your outdoor terminal specifications, please contact our engineering team.

✉️ 961531917@qq.com

🌐 https://lcdmodulepro.com

-

Understanding EMI/EMC risk is crucial for ensuring reliable EV charger performance. Explore this link for expert insights. ↩

-

Exploring serviceability improvements can enhance maintenance efficiency and device longevity, which is essential for outdoor applications. ↩

-

Explore this link to learn how to optimize touch targets for usability in outdoor environments, ensuring user satisfaction. ↩

-

Understanding outdoor readability is essential for designing effective displays that perform well in various lighting conditions. ↩

-

Exploring methods to enhance signal stability can lead to better performance and reliability in your electronic systems. ↩