Replacing an LCD module without modifying the main board sounds straightforward, but success depends on precise electrical, mechanical, and optical compatibility. Many seemingly “drop-in” swaps fail due to subtle mismatches that pass a quick power-up test.

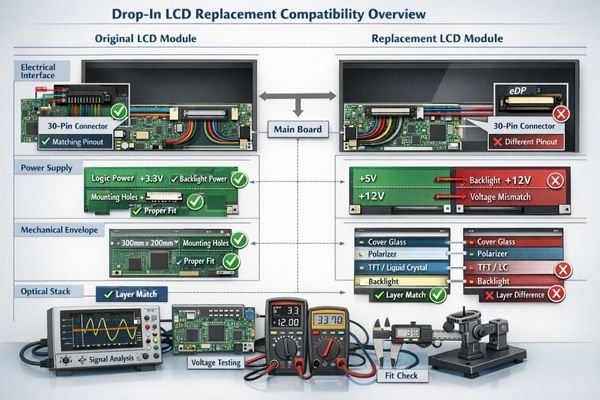

A true drop-in LCD replacement requires exact alignment of four critical factors: electrical interface specifications (including connector pinout), power supply compatibility for logic and backlight circuits, mechanical envelope matching for mounting and cable routing, and optical stack characteristics that preserve readability. If any one factor drifts, you may see black screens, flicker, overheating, or intermittent failures later.

Drop-in replacement is rarely a single-variable decision. A panel can light up during initial testing yet fail during extended runtime, hot/cold exposure, or EMC stress because timing margins, power sequencing, backlight control polarity, or impedance assumptions were never truly compatible.

This article explains what must remain unchanged for main-board compatibility, how to confirm interface and timing when documentation is missing, which electrical failure modes1 appear most often, and how mechanical and optical stack differences can silently break a “no redesign” plan. It ends with a practical shortlist of candidate module families and a validation approach that reduces rework risk.

What must stay the same to replace an LCD module without changing the main board?

Successful replacement requires matching multiple layers at the same time, not just the connector shape. The safest approach is to treat the current main board as a fixed contract and verify every requirement the board expects from the panel.

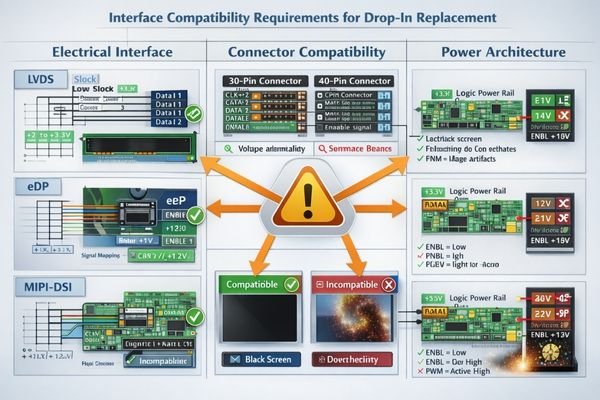

Board-compatible replacement demands precise alignment of three categories: the electrical interface (type, lane mapping, voltage levels, and timing expectations), connector compatibility (physical fit plus exact pin assignment), and power architecture (logic rails, backlight supply range, and dimming/control signaling). A mismatch in any category can cause immediate failure or delayed instability.

Even small differences can produce outsized consequences. A panel that boots once can later fail because the board’s power sequencing does not match the panel’s requirements, or because the backlight driver is operating outside its intended current range. Treat “it shows an image” as a starting signal, not a pass result.

Interface Type and Timing

The interface family (such as LVDS, eDP, or MIPI-DSI) must match the board’s transmitter and routing. Beyond that, the board’s expected resolution, refresh rate, lane count, and clocking constraints must fit the new panel’s timing window. If the system uses fixed timing tables, a panel that is electrically similar may still be unstable.

Power Supply Compatibility2

Logic voltage rails must match, including any requirements for sequencing and enable timing. The backlight path must also be compatible: LED string voltage range, current capability, and dimming method (PWM or analog) should align with the existing driver. Incorrect assumptions here can lead to dim output, flicker, overheating, or long-term lifetime loss.

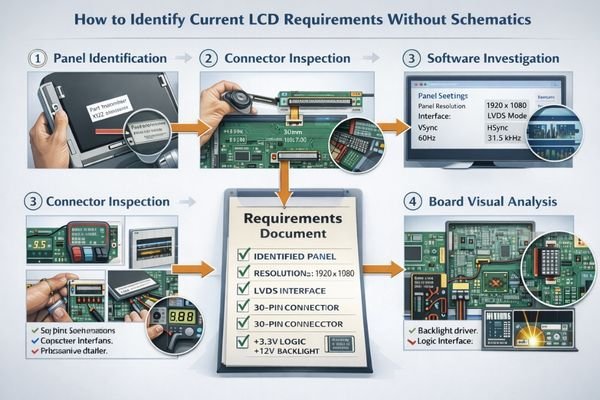

How can you confirm your current interface and timing when you don’t have schematics?

When schematics are unavailable, compatibility work starts with evidence the system already provides. The goal is to identify interface type, key timing constraints, connector and pinout assumptions, and the board’s power architecture without introducing avoidable risk.

A practical investigation relies on four sources: the existing panel label or part number to trace published specifications, connector inspection to confirm pin count and mechanical constraints, system software or firmware configuration to reveal resolution and timing expectations, and board-level visual inspection to identify backlight and logic power architecture. Combine these to define what “compatible” truly means.

Start with the least invasive methods first. A readable panel part number and connector identification often narrow the candidate set dramatically. If software access is available, the configured resolution, refresh rate, and link parameters can confirm whether the board is operating LVDS, eDP, or MIPI-DSI3 and what it expects at boot.

Next, inspect the board for clues about backlight power delivery. A dedicated boost stage, driver IC location, and dimming signal routing can reveal whether the system is designed for a specific LED string configuration or current range. Only after these steps should measurement be considered, and it should be done with clear pin mapping to avoid accidental shorting or overstress.

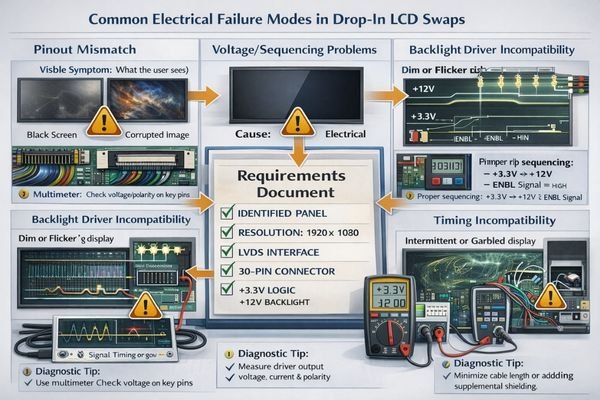

What are the most common electrical failure modes in "drop-in" LCD replacements?

Most drop-in failures are caused by a small set of electrical mismatches that are easy to overlook during a quick bench test. Understanding these patterns helps prioritize verification and avoid the most expensive mistakes.

Three mismatch categories cause most failures: pinout incompatibility where identical connectors carry different signals, voltage level or sequencing differences that destabilize logic and power rails, and backlight driver incompatibility involving LED string configuration and dimming control polarity. Timing mismatches and EMI sensitivity can also appear later, even if the screen initially lights up.

Electrical issues often present in predictable ways, but the first symptom is not always the root cause. A black screen can be pinout, power enable, or link training; flicker can be timing margin, backlight control, or rail droop; intermittent blanking can be EMI sensitivity that only appears with the final cable routing and enclosure grounding.

| Failure Mode | Typical Symptom | Likely Root Cause | Primary Check |

|---|---|---|---|

| Pinout mismatch4 | No image or abnormal behavior | Same connector, different signal assignment | Pin mapping verification against panel spec |

| Voltage / sequencing mismatch | Unstable boot, resets, artifacts | Wrong rail levels or enable order | Power rail compatibility and sequencing review |

| Backlight driver mismatch | Dim, flicker, shutdown | LED string/current range or dimming polarity mismatch | Driver capability vs LED requirements |

| Timing incompatibility | Intermittent image, link drops | Clocking or lane mapping outside margin | Interface constraints vs panel timing window |

| EMI sensitivity | Random blanking under stress | Impedance, routing, grounding interactions | Extended runtime and EMC-aware testing |

Pinout verification should happen before extended power-on testing. Connector similarity is not evidence of signal compatibility, and pinout mistakes can create immediate damage risk.

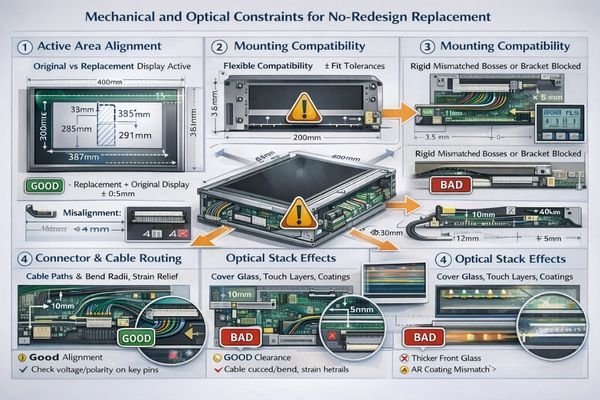

What mechanical and optical constraints decide whether a replacement is truly "no redesign"?

A replacement can be electrically compatible and still fail as a “no redesign” change. Mechanical tolerances, active area placement, and cable routing clearances are often the first obstacles during assembly, while optical stack differences can degrade readability even when brightness specs look similar.

True “no redesign” replacement requires four alignments: the active area must land correctly within the existing window, the outline and mounting points must fit current brackets and bosses, the connector location must preserve cable routing space and bend geometry, and the front optical stack must not introduce thickness or reflectance changes that reduce perceived brightness and contrast.

Mechanical fit is about more than outer dimensions. A small shift in active area position can misalign UI elements, produce uneven bezel borders, or create visible edge shadows. Cable routing problems are also common when a connector moves a few millimeters, forcing tighter bends or different strain relief than the enclosure was designed to allow.

Mechanical Envelope and Cable Routing

Confirm active area placement5 relative to the bezel window, not just the panel outline. Verify mounting hole locations, boss heights, and tolerance stack-up so the module can sit flat without stress. Ensure the flex or harness bend radius, connector clearance, and strain relief fit the existing routing corridor throughout the full assembly process.

Optical Stack, Readability, and Perceived Brightness

A cover glass or touch layer can reduce transmission and increase reflections, making the new screen appear dimmer or more mirror-like at the same nit rating. Differences in haze, coatings, and polarizer behavior can also change contrast under ambient light. Validate readability under realistic lighting, not only in a controlled indoor environment.

Which MEIDAYINGNUO models could be candidates for replacing an existing screen without changing the main board?

After electrical, mechanical, and optical constraints are defined, candidate selection becomes a controlled screening step. Without interface type, pinout, timing, and power details, no model can be guaranteed as a true drop-in, but shortlist candidates can accelerate feasibility checks.

MEIDAYINGNUO supports replacement projects by aligning module selection with board constraints, then validating the complete integration path: pin mapping, power compatibility (logic and backlight), mechanical envelope fit, and optical stack impact on readability. The table below lists common candidate directions to begin compatibility screening within the allowed model pool.

| Clinical Role/Application | Usage Pattern | Display Requirements | Recommended Model | Key Integration Considerations |

|---|---|---|---|---|

| Bar-display replacement in an existing window | Continuous status or dashboard | Ultra-wide mechanical envelope match | BU156X | Verify connector position, pinout, and cable bend corridor |

| Larger bar-display swap with stable bay geometry | Mixed UI + telemetry | Ultra-wide active area and timing constraints | BU215X | Confirm timing margin and backlight control compatibility |

| Square window replacement for compact devices | Menu-driven UI | Square opening alignment and mounting | SQ220S | Check active area placement and mounting point tolerance stack |

| Brightness upgrade under fixed main-board limits | Semi-outdoor readability | Higher luminance with stable power behavior | HB215X | Validate backlight driver capacity and enclosure thermal margin |

| Outdoor-oriented upgrade with stronger ambient load | High ambient light exposure | Higher brightness under reflection control needs | HB238X | Confirm LED string range, dimming polarity, and long-run stability |

FAQ

Can I upgrade to a higher-brightness LCD module without changing the main board?

Sometimes, but only if the existing backlight driver supports the required voltage/current range and the same dimming method. Higher brightness often increases power and heat, so thermal margin and any driver protection behavior must be validated.

If the connector looks identical, does that guarantee pin compatibility?

No. Identical connector families can carry different signal assignments. Pin mapping verification is essential before extended testing, because pinout mismatches can cause no image, unstable behavior, or potential hardware damage.

Why might a new panel look dimmer despite having the same nit rating?

Front stack differences such as cover glass, touch layers, coatings, and haze can reduce transmission and raise reflections. These changes lower effective contrast and perceived brightness under ambient light, even if the datasheet luminance looks similar.

What minimum information should I collect before attempting a replacement?

Collect the current panel part number, connector type and pin count, resolution and refresh rate, interface type, and backlight requirements including voltage range, current target, and dimming method. These define the drop-in feasibility boundary.

Can firmware limitations prevent hardware-compatible replacements?

Yes. Some systems use fixed timing tables, lane mappings, or initialization sequences. A panel that is electrically similar may still require configuration updates to be stable across temperature and runtime, especially for link training and power sequencing behavior.

How should I validate compatibility before committing to production?

Validate pinout and power sequencing first, then confirm timing stability, thermal behavior at sustained brightness, and long-duration operation across temperature. Include real cable routing and enclosure grounding, because intermittent blanking and EMI sensitivity often appear only in the final mechanical environment.

Conclusion

Replacing an LCD module without changing the main board is achievable when interface type, pinout, power rails, and timing expectations align, and when mechanical envelope and optical stack differences do not introduce fit or readability regressions. Treat drop-in replacement as a verification process, and validate stability, thermal margin, and long-run behavior before scaling to production.

MEIDAYINGNUO supports drop-in and near drop-in replacement projects by screening candidates against electrical and mechanical constraints, then validating the full integration path with realistic runtime and environmental conditions. If you want help confirming compatibility and selecting candidates, contact us using the email below.

✉️ info@lcdmodulepro.com

🌐https://lcdmodulepro.com/

-

Exploring electrical failure modes helps in identifying potential issues early, ensuring better design and reliability. ↩

-

Understanding power supply compatibility is crucial for device performance and longevity. Explore this link to learn more. ↩

-

Exploring these display interfaces will enhance your knowledge of how different technologies communicate, improving your troubleshooting skills. ↩

-

Understanding pinout mismatch is crucial for preventing damage and ensuring compatibility in electronic connections. ↩

-

Understanding active area placement is crucial for ensuring optimal alignment and functionality in mechanical designs. ↩