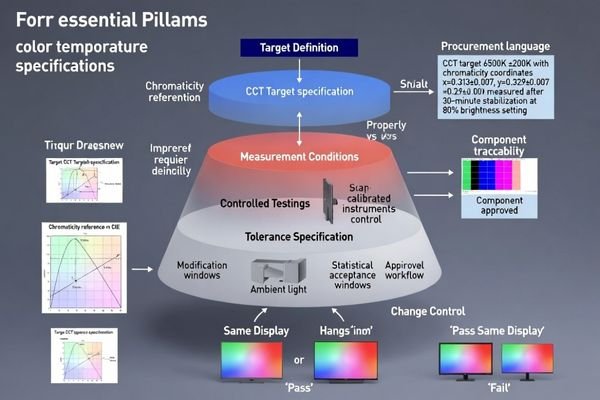

Effective color temperature consistency procurement terms require precise definition of measurement conditions, acceptable tolerances, and change control procedures.

Color temperature consistency procurement terms must define controlled white-point outcomes under specified measurement conditions including target CCT and chromaticity references, measurement methodology and boundary conditions, fair tolerance ranges distinguishing lot-level versus unit-level variation, and lifecycle change control procedures covering backlight binning and optical stack modifications.

In my LCD display module integration work at MEIDAYINGNUO, I’ve found most “color consistency” disputes are not caused by poor supplier capability, but by missing contract mechanics. Without locked measurement conditions, the same module can “pass” on one bench and “fail” on another. A procurement-ready clause1 should read like a closed loop: define the target (CCT plus a chromaticity reference), lock the measurement conditions (instrument, warm-up, brightness/dimming state, geometry, sampling), set tolerances (within-lot vs lot-to-lot), and define a workflow (sampling, retest, dispute resolution, and change control). This reduces false rejects, protects visual consistency across reorders, and keeps service replacements aligned months later.

What does "color temperature consistency" mean in LCD module procurement?

Color temperature consistency must be defined as measurable white-point outcomes under specific operating conditions rather than subjective appearance expectations.

Color temperature consistency should be defined as controlled white-point outcome for LCD display modules under stated conditions including nominal CCT target with corresponding chromaticity reference, specification of consistency requirements across units and production lots, clarification of operating states including brightness levels and dimming regions, and definition of whether requirements apply to bare modules or assembled optical stacks.

From an engineering standpoint, I usually explain that perceived white point is a system outcome: backlight spectrum, optical films, panel behavior, and drive conditions all contribute. The procurement definition must therefore specify the outcome under stated conditions, not a subjective promise of “same color.” It should also state whether acceptance is for a bare module or the assembled optical stack, because cover lenses, coatings, and adhesives can shift chromaticity and create avoidable disputes if inspection conditions don’t match real product evaluation.

Target Definition Requirements

Effective procurement terms establish a nominal CCT target2 and a chromaticity reference so acceptance does not rely on interpretation. CCT alone is easy to communicate but can hide shifts that look “greenish” or “pinkish” while still landing in a similar CCT range, so adding a chromaticity reference (or an agreed color-space tolerance) makes the target enforceable. The clause should also define how the reference is anchored—such as a customer-approved reference and the exact measurement setup—so both sides are evaluating the same definition of “white” rather than arguing over impressions.

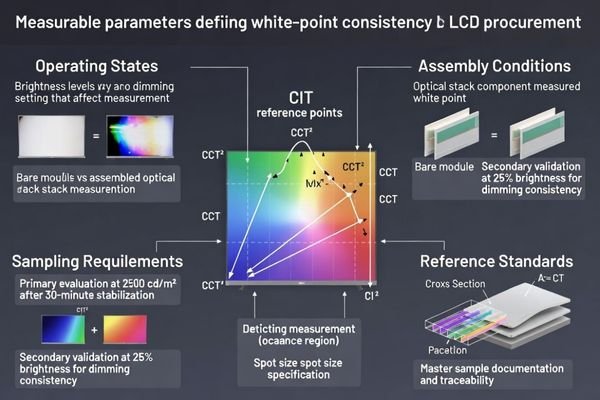

Operating State Specifications

Consistency requirements must state the operating states where white point matters in real use: the brightness level(s), the dimming method, and the warm-up/stabilization timing. White point can shift with backlight drive, temperature, and stabilization, so “measured at any state” is not workable. Define the key inspection points that reflect the user experience (for example, a primary brightness setting plus a dimmed state if used at night or in enclosed cabinets). If the product is judged assembled, specify whether the assembled stack is required for inspection or whether a correlation method will be used.

Which measurement conditions must be locked to make terms enforceable?

Enforceable terms require comprehensive specification of measurement methodology and boundary conditions that control white-point measurement results.

Critical measurement conditions include instrument type and calibration traceability expectations, ambient conditions with stray light control, module warm-up and stabilization timing, exact electrical drive state during measurement including backlight and dimming settings, measurement geometry and sampling rules, and definition of whether optical stack is included during measurement to prevent false rejects.

Based on the projects I support with color consistency validation3, the largest discrepancies typically come from “small” setup differences: different instrument types or calibration status, uncontrolled ambient light, different warm-up timing, or mismatched brightness and dimming settings. To avoid this, procurement terms should lock: the instrument class (and calibration/traceability expectations), stray-light control method (such as a controlled environment or shading), stabilization time, the exact drive state (brightness target and dimming method), and the sampling rule (location and spot size). Also state clearly whether the optical stack is included, or define a correlation method, to prevent false rejects when the final product is judged assembled.

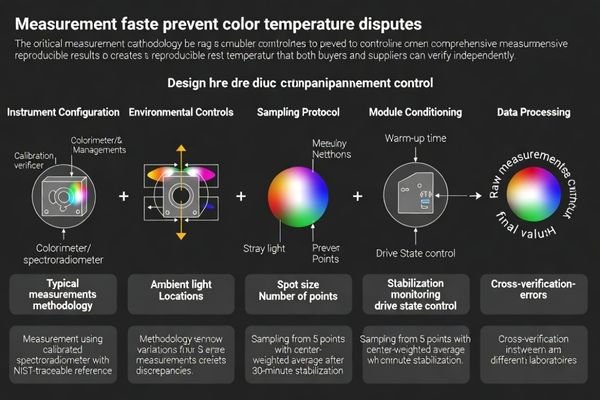

How can you set tolerances that are both fair and manufacturable?

Tolerance specification must balance manufacturing capability with functional requirements while providing clear acceptance criteria.

Fair tolerances should be written as acceptance windows around defined references with rules distinguishing lot-level versus unit-level control requirements, allowable white-point ranges relative to customer-approved reference methods, practical acceptance approaches accounting for measurement uncertainty including lot-based sampling and retest procedures, and methodology for establishing final limits using pilot data anchored to controlled reference standards.

When I troubleshoot color consistency procurement problems, unrealistic expectations often create more disruption than protection—driving rework, sorting, or arguments that don’t improve end-user perception. A workable approach is to set acceptance windows relative to a controlled reference, then define how variation is managed within a lot and across lots. Tolerances should also consider measurement uncertainty, so the workflow supports sampling and retest rather than single-sample conflict. If numeric limits are not finalized early, write the method for finalizing them after pilot data under the agreed measurement setup, so “acceptable” is determined by a shared process rather than opinion.

| Tolerance Type | Application Scope | Typical Range |

|---|---|---|

| Within-Lot Variation | Production consistency | ±200K CCT, ±0.01 xy |

| Lot-to-Lot Drift | Long-term stability | ±300K CCT, ±0.015 xy |

| Reference Matching | Replacement parts | ±150K CCT, ±0.008 xy |

Tolerance ranges should reflect actual measurement uncertainty and manufacturing capability while maintaining functional performance requirements. The ranges above are illustrative examples only; final limits should be confirmed using pilot/production data under the agreed measurement method and evaluation condition.

For expert color consistency specification development and tolerance optimization4 support during procurement planning phases, engineering teams can contact info@lcdmodulepro.com when white-point control requires precise validation methodology.

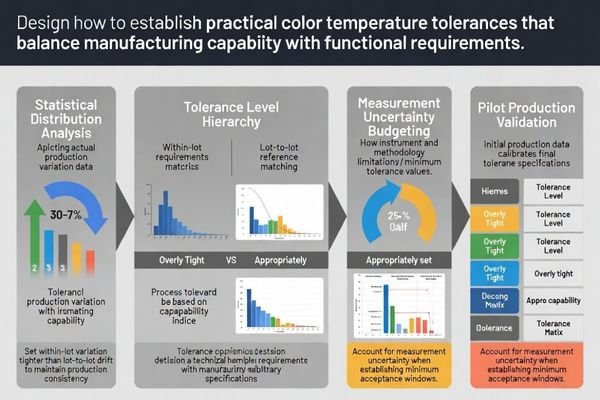

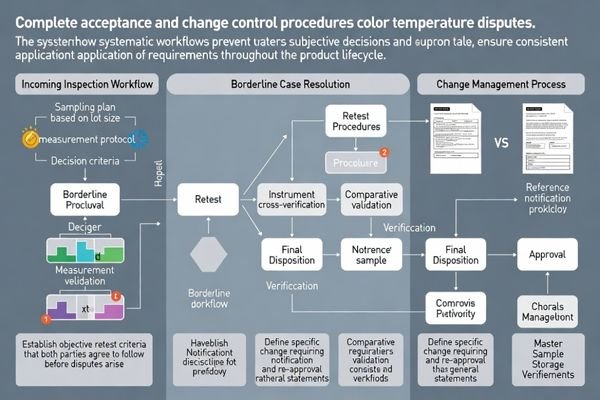

What acceptance and change-control clauses reduce disputes over time?

Effective procurement terms combine objective measurement protocols with clear acceptance workflows and lifecycle change management.

Dispute-resistant terms establish shared references such as golden samples or master reference definitions, define incoming inspection sampling rules tied to lot size, specify borderline result handling including retest procedures and instrument verification, separate functional compliance from appearance grading, and require notification plus re-approval for changes affecting white point including backlight binning and optical film modifications.

I’ve observed that disputes escalate when acceptance drifts over time—because measurement setups change, references degrade or go missing, or suppliers make component substitutions without a defined re-approval path. A robust clause prevents this by combining a shared reference, a repeatable sampling plan, and a clear dispute-resolution path for borderline results. It also separates “functional compliance” from “appearance grading” so the contract does not convert subjective preference into a hard reject. Finally, it protects lifecycle stability by requiring change notification and validation for any modification that can shift white point, ensuring later shipments and spare parts remain visually interchangeable.

Reference Control Procedures

Establish a master reference that both buyer and supplier can use consistently, and define how it is maintained. Specify the reference condition (bare module vs assembled stack), the measurement setup used to create the reference, and how inspection sites verify their instruments (for example, a routine check against an agreed standard or reference unit). Define how sampling is performed (lot-based sampling tied to lot size) and how results are reported. For borderline results, write a clear retest sequence: same unit, same drive state, same conditions, instrument verification, and a disposition rule so the outcome is repeatable rather than negotiated.

Change Notification Requirements

Change control5 should explicitly list trigger items that can move white point: backlight LED binning/spectral characteristics, optical films and diffusers, adhesives/coatings in the optical path, and drive settings or dimming strategy. The clause should require notification, define what evidence is needed (e.g., comparison to the master reference under the agreed setup), and specify when re-approval is mandatory. This is especially important for long programs where suppliers may need to manage component availability. With clear triggers and validation steps, buyers reduce surprises and suppliers avoid unnecessary rejections.

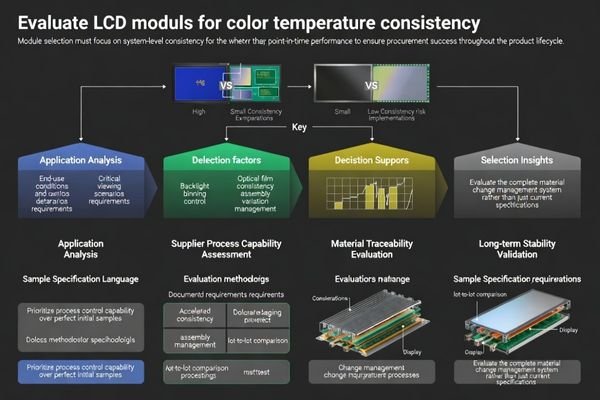

How to choose LCD display modules when white-point consistency is procurement-critical?

Module selection for critical color consistency applications requires prioritizing controllability and process stability over initial sample appearance.

Selection strategy should prioritize controllability and repeatability by defining real evaluation conditions including assembled optical stack requirements, brightness and dimming states affecting user perception, and acceptable risk levels for operators or end users, then evaluating suppliers on backlight spectral control capability, optical stack stability, and critical material traceability determining lot-to-lot consistency and replacement part matching.

Based on my experience with color-critical applications, long-term consistency depends more on supplier process control and change management than on achieving a “perfect” white point in a single early sample. Start by defining how the product is truly judged (assembled vs bare), then align the measurement and acceptance method to that condition. Next, evaluate whether the supplier can control the main drivers of drift—backlight spectral variation, optical stack stability, and traceability of critical materials—because these determine lot-to-lot behavior and spare-part matching. Also confirm that the module is driven in a stable, repeatable way in your system (brightness/dimming state and power stability), so procurement measurements are not distorted by unstable drive conditions.

White-Point Consistency Optimization Framework:

- Process Control Assessment: Evaluate supplier capability for backlight LED binning control, optical film specification stability, and assembly process repeatability affecting white-point variation

- Material Traceability Requirements: Establish documentation and change notification procedures for critical components including LED suppliers, optical film sources, and adhesive specifications

- Validation Methodology Development: Define measurement protocols, reference standards, and acceptance workflows that can be reproduced across sites and maintained over product lifecycles

- Lifecycle Continuity Planning: Implement change control procedures, reference retention strategies, and continuity validation methods ensuring consistency across production ramps and service requirements

FAQ

Should I specify only CCT, or also chromaticity coordinates?

CCT is easy to communicate but can hide meaningful chromaticity shifts; adding chromaticity coordinates (or an agreed color-space tolerance) makes acceptance more precise and reduces disputes.

Do I need to define warm-up time in the procurement spec?

Yes. White point can shift during stabilization, so warm-up and the measurement timing should be fixed to ensure both sides evaluate the same steady-state condition.

Should inspection be done on the bare module or the assembled cover lens/touch stack?

It should match how the product is judged in reality; if the assembled unit is the decision basis, align procurement and incoming inspection to the assembled condition or define a correlation method.

How can I avoid "false rejects" caused by different measurement setups?

Lock instrument type and calibration expectations, ambient light control, geometry/spot size, brightness setting, and sampling locations, and include a retest/cross-check procedure for borderline results.

What changes should trigger supplier notification and re-approval?

Any change that can shift white point—backlight LED binning, optical films/diffusers, adhesives/coatings in the optical path, or drive settings—should trigger notification and a defined validation step.

How do I keep replacement parts visually consistent months later?

Use a master reference, define lot-to-lot limits, enforce change control, and include continuity planning so later lots are validated against the same reference under the same method.

Conclusion

Color temperature consistency becomes procurement-ready when defined as measurable white-point targets under fixed conditions, supported by fair tolerances, repeatable acceptance workflows, and comprehensive lifecycle change control. Effective procurement terms align measurement conditions with real product evaluation methods while reducing disputes through controlled references and systematic retest procedures. Success comes from treating white point as a system outcome—backlight, optical stack, and drive conditions—so requirements are enforceable for buyers and achievable for suppliers over production ramps, reorders, and service spares.

MEIDAYINGNUO can support LCD display module procurement planning where white-point consistency is critical, including measurement method alignment, tolerance-setting based on pilot data, and acceptance/change-control workflow design. Contact our technical team when color temperature consistency requirements need clearer, more enforceable specification language and validation planning.

✉️ info@lcdmodulepro.com

🌐 https://lcdmodulepro.com/

-

Exploring procurement-ready clauses can enhance your contract mechanics, ensuring better supplier relationships and product quality. ↩

-

Understanding the nominal CCT target is crucial for ensuring consistent color quality in products, making this resource invaluable. ↩

-

Understanding color consistency validation is crucial for ensuring accurate color reproduction in various projects. ↩

-

This resource will provide insights into tolerance optimization techniques that enhance product quality and reduce rework. ↩

-

Exploring best practices in change control can help streamline processes and minimize disruptions in production. ↩