Outdoor readability failures rarely come from “too few nits” alone. Glare, sun angle, cover glass reflections, and enclosure heat limits can turn a high-brightness spec into a poor user experience in real installations.

For semi-outdoor use, 700–1000 nits is often a practical start, while direct-sun outdoor installs typically need 1500 nits or more—plus strong reflection control. The right target depends on exposure (shade vs sun), mounting geometry, and the optical stack (cover glass, touch, AR/AG, bonding). Validate with worst-case sun angles and thermal soak so end-of-life brightness still meets readability.

Brightness selection is a system decision, not a single-number choice. In outdoor and semi-outdoor environments, effective contrast is driven by both luminance (cd/m², “nits”) and how much ambient light the front surface reflects back to the viewer. Even a bright module can look washed out if reflections dominate the viewing direction, especially under low-angle sun.

This article explains how to map brightness tiers to exposure conditions, how mounting orientation and surrounding surfaces shift real requirements, and how optical and mechanical choices reduce glare1 so you can avoid overdriving power and heat. It also outlines a validation approach that includes worst-case sun angles, the full cover/touch stack, thermal limits, and aging margin.

What brightness (nits) ranges typically match semi-outdoor vs outdoor LCD use?

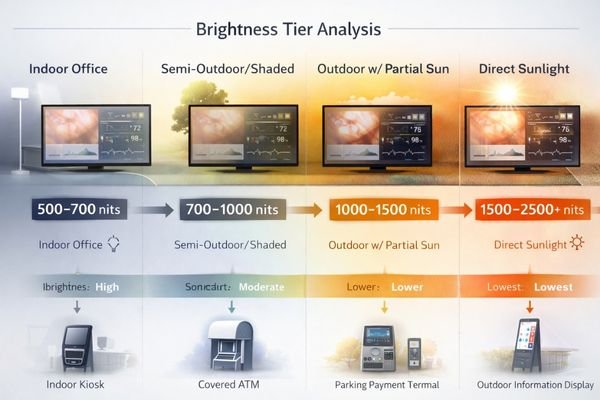

Picking a nit target is easiest when you start from exposure intensity rather than labels like “outdoor.” Semi-outdoor shade, indirect outdoor light, and direct sun behave very differently, and each can move your required brightness by a full tier.

As a baseline, 500–700 nits often fits bright indoor or near-window use, 700–1000 nits commonly works for shaded semi-outdoor installations, 1000–1500 nits suits many outdoor installs with some shading or controlled viewing angles, and 1500–2500+ nits is typically where direct-sun outdoor readability begins—then adjust for reflections, cover glass losses, and geometry.

These ranges are starting points, not guarantees. Real readability depends on whether sunlight can hit the screen at low angles, how reflective the front stack is, and whether the installation is recessed or shaded. Treat brightness as the last lever after you reduce reflection paths and control the viewing direction.

Application Context Mapping

Semi-outdoor usually means the display is under a roofline or canopy, protected from direct precipitation, and viewed from more predictable angles. Outdoor use typically includes some direct sun exposure during the day and larger temperature swings. If direct sun can reach the screen at any time, size your brightness and reflection control for outdoor conditions.

Environmental Load Assessment

Seasonal sun paths and nearby reflective surfaces can raise the effective ambient load2 beyond what a quick inspection suggests. Light pavement, glass building facades, water, and metal cladding can create strong glare sources. These conditions often demand either a higher nit tier or better reflection suppression, even if the installation is nominally “shaded.”

How do ambient light, sun angle, and mounting location change the brightness you need?

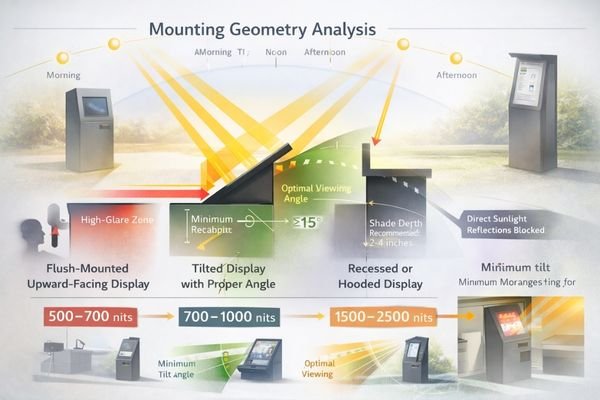

Two displays with the same nits can look completely different outdoors because geometry determines glare. Orientation to the sun, the tilt angle, bezel depth, and nearby reflective surfaces all influence how much light is redirected into the user’s eyes.

Brightness requirements are highly geometry-dependent: horizontal or upward-facing screens receive more sky light and glare, east/west-facing screens are punished by low-angle morning or afternoon sun, and flush mounting increases reflection paths—while recessing, deep bezels, or a hood can often reduce glare enough to drop the needed brightness tier.

A practical way to think about this is “glare probability3.” If the display surface can reflect a bright source toward the user’s typical viewpoint, the perceived contrast collapses and extra nits offer diminishing returns. Mechanical design that blocks or redirects incident light often improves readability more efficiently than raising backlight power, while also reducing thermal stress.

What optical and mechanical choices can reduce the brightness you need?

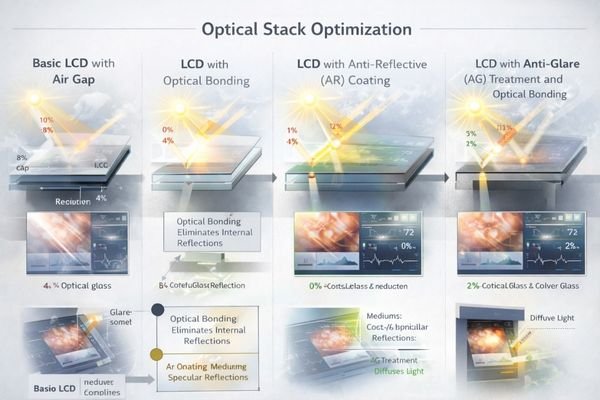

Outdoor readability frequently fails due to reflections rather than insufficient luminance. Reflection control increases effective contrast so the same UI remains readable at a lower nit target, reducing power and heat risk in sealed enclosures.

Optical bonding can reduce air-gap reflections and internal glare, AR coatings can lower specular reflection intensity under sun, AG treatments can diffuse glare hotspots (with possible sharpness trade-offs), and polarizer selection can improve perceived contrast in high ambient light—often allowing a lower brightness target to meet the same usability requirement.

From an engineering perspective, these options should be chosen as a stack, not individually. A cover lens or touch layer can add reflectance and reduce transmittance, so it is common to pair reflection suppression with a brightness tier that stays inside your thermal envelope and lifetime target.

| Optical / Mechanical Option | Primary Benefit Outdoors | Key Trade-off to Watch |

|---|---|---|

| Optical bonding | Reduces internal reflections and improves perceived contrast | Process complexity and rework strategy |

| AR coating4 | Lowers specular reflection intensity in direct sun | Stack-dependent durability and cost |

| AG treatment | Diffuses glare hotspots for better legibility | Possible sharpness and sparkle trade-offs |

| Polarizer optimization | Improves contrast impression under high ambient light | Interaction with cover stack and angles |

Choose the combination based on your exposure, UI sensitivity to haze/sharpness, and enclosure constraints. If glare is the dominant failure mode, improving reflection control can be more effective than pushing nits higher.

How should you validate the right brightness level before committing to mass production?

Validation must reflect worst-case reality, not best-case lab conditions. The goal is not “maximum nits,” but consistent readability with your final optical stack, mounting geometry, and enclosure thermal behavior across the full operating life.

Validate brightness by testing readability at multiple sun angles (especially low-angle glare), using the complete optical stack (cover glass and touch if applicable), confirming sustained high-brightness thermal behavior, and applying an aging margin so end-of-life luminance still meets your pass/fail readability criteria at the intended viewing distance and angles.

Start by defining a measurable pass/fail criterion that matches your UI: critical font size, viewing distance, acceptable glare level5, and whether users must read the screen quickly or continuously. Then reproduce the real mounting geometry—tilt, bezel depth, and any hood—because small changes can shift reflection paths and perceived contrast dramatically.

Worst-Case Exposure Testing

Test at the intended site (or an equivalent sun path) across the day, prioritizing morning and afternoon when low-angle sun creates the harshest specular glare. Evaluate readability from expected user positions, not only straight-on. Record ambient conditions and note when reflections dominate; this is often where a design fails despite high luminance.

Thermal Soak and Aging Margin

Run sustained high-brightness operation in the final enclosure to confirm temperature rise, color shift behavior, and stability. Apply a practical aging margin so the design remains readable at end of life, not just at day-one peak output. If thermal limits force dimming, the best time to discover it is during validation, not after deployment.

Which MEIDAYINGNUO module models fit common outdoor brightness targets?

Moving from brightness theory to product selection is where many projects lose margin. Once exposure, reflection control, and mounting geometry are defined, choosing a module family that supports your target nit tier—within power and thermal limits—becomes straightforward and much lower risk.

MEIDAYINGNUO focuses on outdoor high-brightness LCD display modules designed for challenging ambient light conditions. In engineering terms, the goal is to match panel size and brightness capability to your enclosure heat budget, then confirm readability with the actual cover/touch stack and mounting geometry. The models below align with common outdoor and semi-outdoor integration patterns.

| Clinical Role/Application | Usage Pattern | Display Requirements | Recommended Model | Key Integration Considerations |

|---|---|---|---|---|

| Outdoor HMI / control cabinet | Frequent glance viewing | High contrast under mixed sun/shade | HB156X | Recess/hood design, thermal path for sustained high brightness |

| Compact outdoor kiosk | Intermittent interaction | Sunlight readable with cover glass | HB185X | Reflection control for touch stack, verify low-angle glare cases |

| Mid-size outdoor terminal | Mixed day exposure | Stable readability with controlled angles | HB215X | Enclosure airflow/heat sinking, validate end-of-life margin |

| Outdoor signage / panel | Longer viewing distance | Wide-area legibility in bright ambient | HB238X | Front-surface reflections, mounting angle optimization |

| Large-format outdoor display | Continuous visibility | Strong ambient resistance and uniformity | HB270S | Power/thermal planning, glare mitigation, field validation protocol |

FAQ

Is “nits” the only specification that matters for outdoor readability?

No. Outdoor readability is dominated by effective contrast, which depends on reflections from the cover/touch stack and mounting geometry as much as on luminance. Managing glare often determines whether a screen is usable.

What’s the practical difference between semi-outdoor and outdoor installations?

Semi-outdoor typically means consistent shade and more controlled viewing angles, while outdoor implies stronger ambient light and potential direct sun during part of the day. If direct sun can hit the surface, treat it as outdoor.

Can a hood or recessed mounting reduce my required brightness?

Often yes. A hood or recess can block incident light and shift reflection paths away from typical viewing positions, effectively improving perceived contrast. Always validate under low-angle sun when glare is strongest.

How do cover glass and touch layers affect brightness selection?

They can increase reflections and reduce transmittance, which may push you into a higher nit tier or require stronger reflection suppression (bonding, AR/AG). Validate with the final stack, not a bare panel.

What should I test before locking mass production brightness?

Test worst-case sun angles, the complete optical stack, sustained thermal behavior at high brightness, and end-of-life readability with aging margin. Confirm readability from real user distances and angles, not only straight-on.

Conclusion

Outdoor brightness selection works best when you start from exposure intensity, then maximize effective contrast through reflection control and mounting geometry before raising nits. Validate using worst-case sun angles, the final cover/touch stack, and thermal soak testing, and include an aging margin so end-of-life performance still meets your readability criteria.

MEIDAYINGNUO provides outdoor high-brightness LCD display modules and engineering support for optical stack and integration planning. If you want help mapping your installation conditions to a brightness tier and validation plan, contact our team using the email below.

✉️ info@lcdmodulepro.com

🌐https://lcdmodulepro.com/

-

Exploring glare reduction techniques can significantly enhance viewer experience and display visibility. ↩

-

Exploring ambient load helps in assessing the impact of environmental factors on display visibility and effectiveness. ↩

-

Understanding glare probability can help improve display design for better readability and user experience. ↩

-

Learn about AR coating’s role in reducing glare and enhancing durability for outdoor applications. ↩

-

Understanding acceptable glare levels is crucial for ensuring optimal screen visibility and user comfort in various lighting conditions. ↩